Injection mold is an indispensable tool in the plastic processing industry, which determines the quality and cost of plastic products. For many enterprises and individuals, determining the price of injection molds is a critical issue. The following content mainly describes the determinants of injection mold prices, to help customers understand and choose the right price.

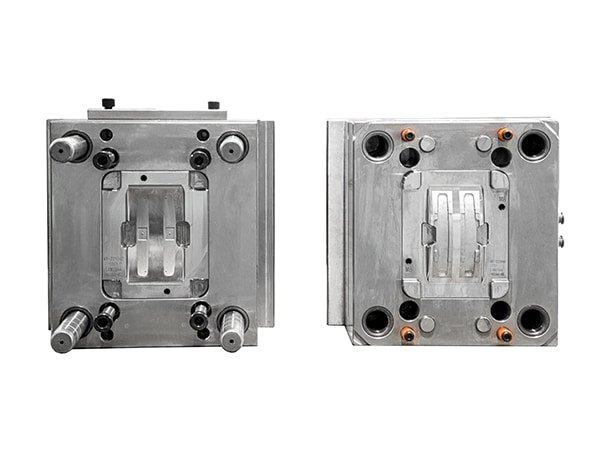

The complexity and scale of the mold

First, the price of injection molds is affected by many factors. Among them, the most important factor is the complexity and scale of the mold. The complexity of the mold includes the complexity of the product shape, the number of parts required in the mold, and the mold opening method. In general, the price of a mold with a complex shape, a large number of parts, and a more complex mold opening method is higher. In addition, the size of the mold is also an important factor affecting the price, and the price of large-scale injection molds will be relatively high.

Mold material selection

Secondly, the price of injection molds also depends on the choice of materials. Common injection mold materials include plastics, metals, alloys, etc. The cost and performance of different materials are also different, so the choice of materials will directly affect the price of the mold. In general, metal and alloy materials are more durable and stable, but the price is also relatively high. Plastic materials are cheap but have a relatively short lifespan. Companies need to weigh the cost and performance of different materials when making injection mold choices.

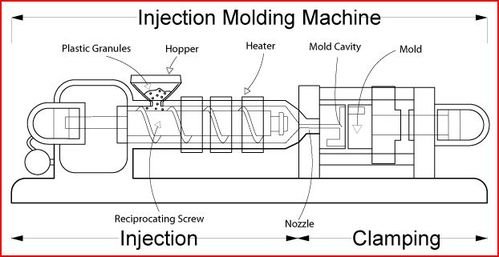

Processing technology

In addition, the accuracy and quality requirements of the injection mold will also have an important impact on the price. High-precision and high-quality injection molds require higher-quality materials and more complex processing processes, so their prices are relatively high. At the same time, the technical strength and professional level of the mold manufacturer will also directly affect the quality and price of the mold. Therefore, enterprises need to consider their technical strength and reputation when choosing mold suppliers.

Market factor

In addition to the above factors, market supply and demand relations and regional differences will also have an impact on the price of injection molds. For example, supply and demand and the degree of market competition are important factors in determining prices. In the case of oversupply, mold prices may be relatively low, and supply shortages may lead to price increases. In addition, the level of economic development and industrial demand in different regions will also affect the price difference of molds, and the price of molds in economically developed regions and regions with strong demand is relatively high.

In summary, the price determination of injection molds is affected by several factors, including the complexity and scale of the mold, material selection, accuracy and quality requirements, market supply and demand relations, and regional differences. Customers need to weigh various factors when choosing injection molds and choose the right price and supplier. Only in this way can we meet the requirements of product quality and cost and promote the sustainable development of enterprises.

If you are looking for a professional Mold factory, please contact BFY Mold. Whether it is mold design or injection molding, we have a one-stop service.