About Us

Home – About Us

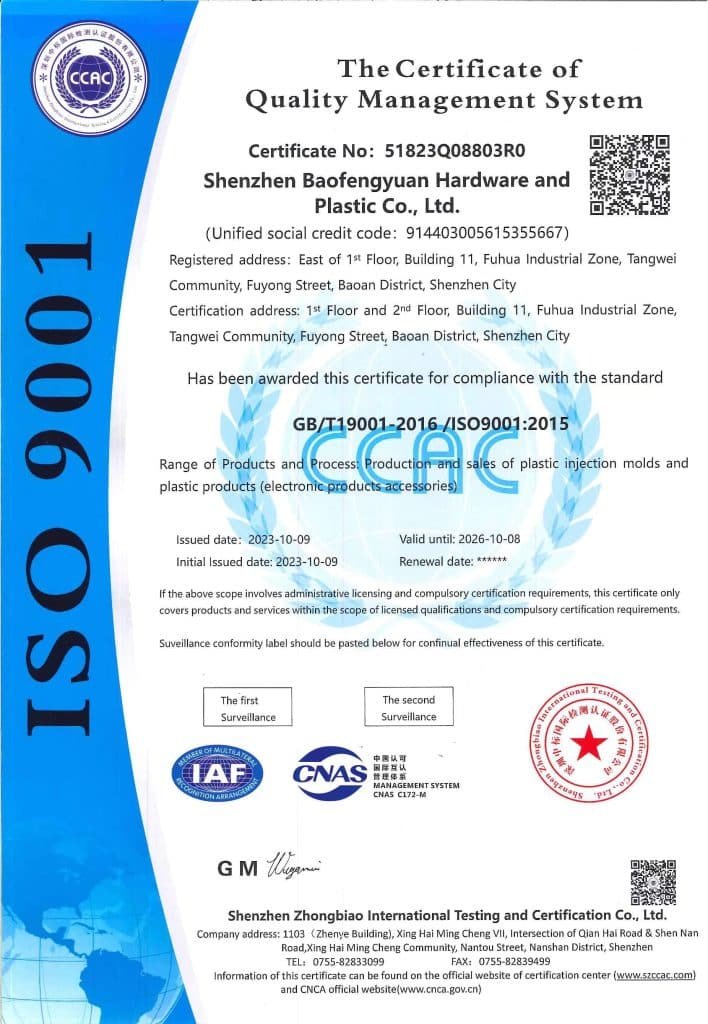

Your ISO Certificated Injection Molding Company

20 years of industry experience

- Established in 2010, Shenzhen Baofengyuan Hardware And Plastic Co., Ltd. is dedicated to evolving traditional manufacturing processes and has several engineers with more than 20 years of industry experience.

Strong Manufacturing Capabilities

- At the heart of Baofengyuan’ s success lies strong manufacturing capabilities. Equipped with senior engineers and advanced machinery, we deliver exceptional precision and efficiency in every project. From CNC machining, injection molding, and sheet metal fabrication to 3D printing and more, our extensive manufacturing capabilities cover a wide spectrum of industries and applications.

One-stop Solution

- Whether prototyping, low-volume production, or high-volume manufacturing, we offer an extensive range of manufacturing services that cater to diverse requirements. With a team of skilled engineers and state-of-the-art facilities, Baofengyuan ensures a seamless transition from concept to final product, saving time, effort, and resources for our clients.

Forged in Unity, Mold Success Transcends Every Challenge!

Injection Mold Place

Injection Molding Machine

CNC Machining Place

Production Parts Warehouse

How to Start Injection Molding Order?

Develop a precise plastic injection mold design according to your specifications, our expert technicians handle all complexities involved in the mold production process. Quickly customizing product molds, allows you to quickly test prototype parts and bring them to market faster.

For customers’ common injection molding problems, you can browse this section for a quick understanding.

How can I get a quote?

Please email us with the project specification, and attach the part design drawing (STEP/IGS/DWG/PDF/CAD/ etc) .

If you would like to purchase plastic injection molds, the information that needs to be told are mold steel, plastic material and surface requirements of the part, the mold life, and the runner system you would like to use.

If you want to purchase the molded plastic parts, please tell us the specific plastic material, the production quantity, the part surface treatment, and the color of the plastic parts.

How soon will I get the quote after I submit my request?

1 to 3 days. Usually within 24 hours. However, if your project is a large or difficult one, we need more time to provide a reasonable quote.

I have the pictures for the parts/products, can I get a quote?

For some relatively simple products with simple structures, it’s good to quote only the product photos.

Please send us the pictures of all the dimensions and tell us the weight, that would be good. If the part is structurally complicated, and you don’t have the CAD design drawing, you could send the part to us by express, so that we give you the quote with the sample in hand.

Is there a MOQ (Minimum Order Quantity)?

BFY Mold does not have a minimum order policy. Our sales and engineers will help recommend the right injection mold and molding solution for you.

Do you have any after-sales service?

Yes, we provide after-sales service. After the mold is exported, our sales engineers will continue to follow up the molding situation. At this stage, if the mold breaks down, our engineers will be involved in the evaluation process and help to solve the problem.

Do you have injection machine for mould test?

Yes, we have 90T, 160T, 250T, 320T, 390T, 400T, 450T, 650T, 800T injection machine for mould test and production.

How do you guarantee my design not be plagiarized or copied?

These are how we guarantee:

- Our customers could sign the NDA (Non-Disclosure Agreement) with BFY Mold to ensure that we will not plagiarize the design.

- We are an OEM injection mold manufacturer, and we do not have any channels and genes to sell such products, that’s one of the reasons we don’t plagiarize or copy the part design.

- For most projects, injection molded items are only parts of the product, which effectively prevents the whole product from being duplicated by manufacturing in one supplier.

How long to make a plastic injection mold?

Depending on the complexity of the product, it usually takes 4 to 6 weeks to manufacture a set of molds. Delivery times will be listed on the quotation for reference before the order is started.

Feedback From Plastic Injection Molding Partners