Surface Finishing Service

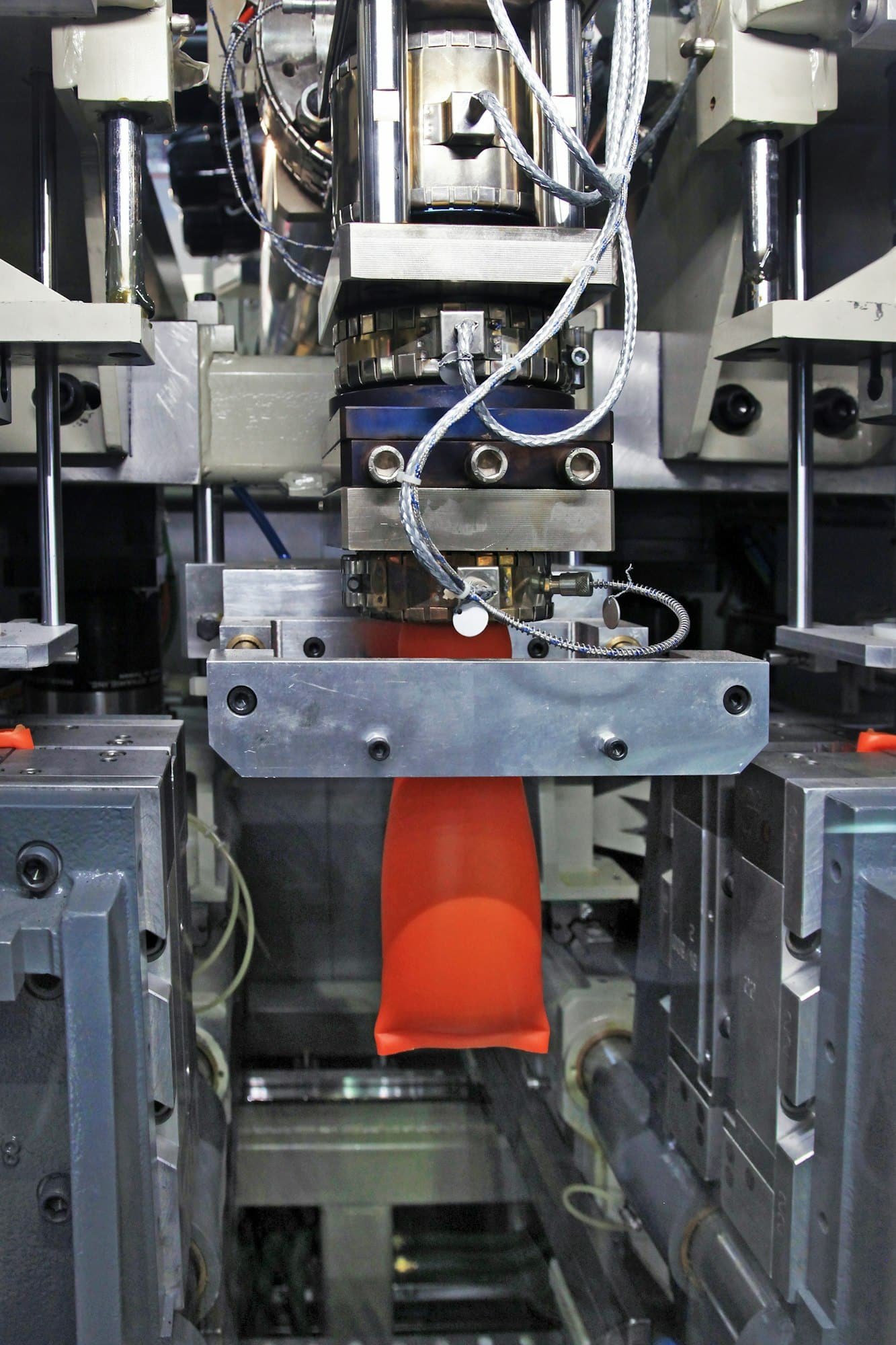

As specialists in injection molding, we take pride in offering a comprehensive suite of surface treatment and processing services that elevate the quality and performance of our molded parts.

Our Surface Finishing Capabilities

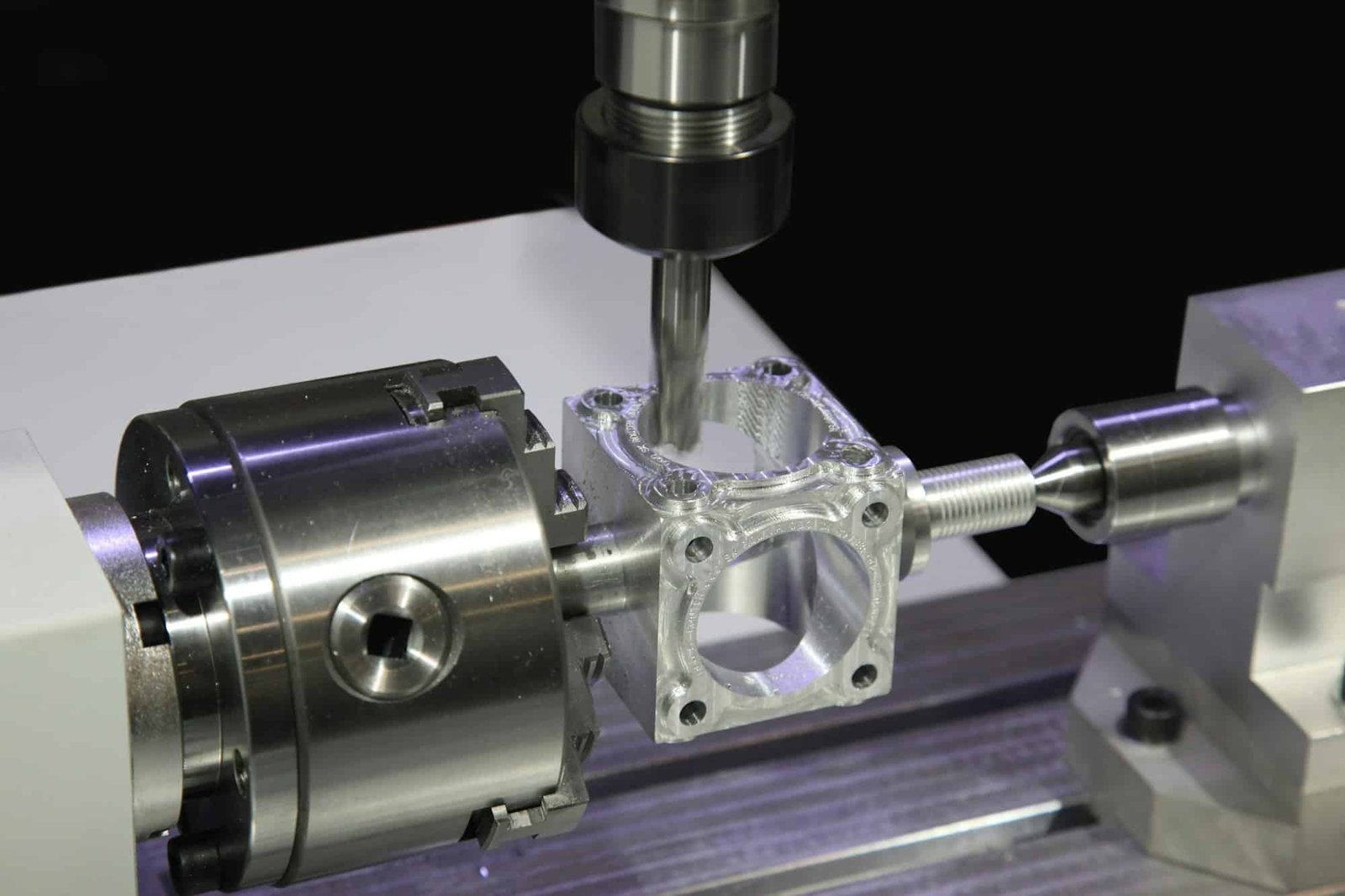

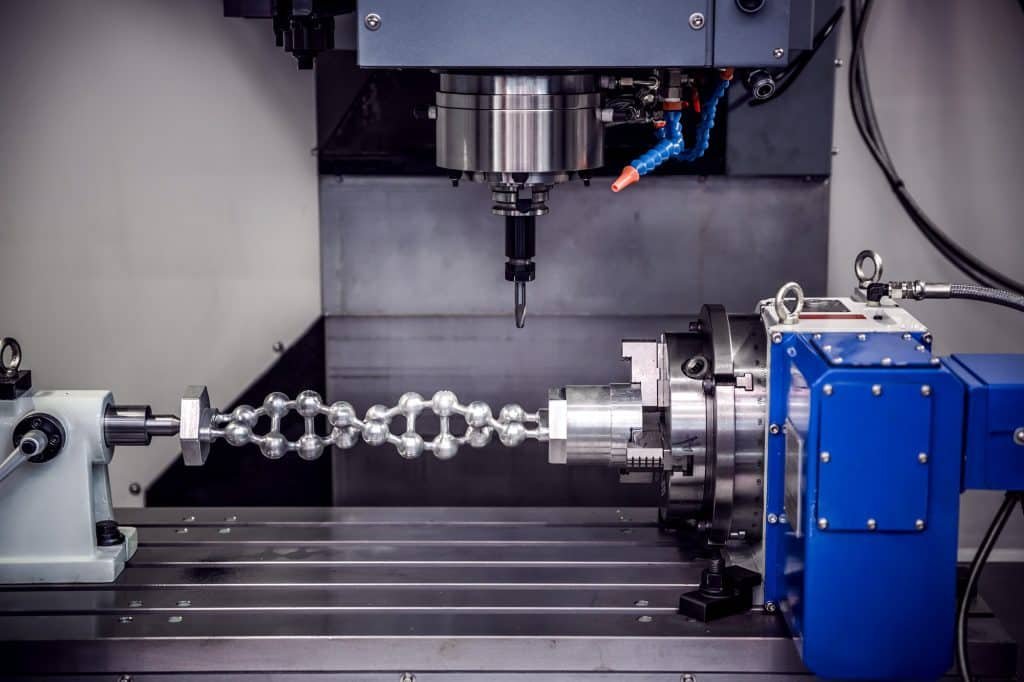

Our journey begins with precision in mold design and processing. Armed with state-of-the-art technology, our factory ensures the creation of molds with unparalleled accuracy, catering to diverse needs and specifications. Every mold is a testament to our commitment to precision engineering.

In the realm of injection-molded parts, surface treatment is a critical step in enhancing both functionality and aesthetics. Our surface treatment services are tailored to optimize the visual appeal and performance of molded components. From precision polishing to texture application, our experts apply techniques that elevate the quality of injection-molded parts.

Our surface treatment protocols are not just a matter of craftsmanship; they are rooted in data-driven optimization. Through extensive research and analysis, we fine-tune our treatments to align with the specific requirements of each injection-molded part. This approach ensures optimal performance and longevity, backed by quantifiable data.

Our Services

Explore More About Us

- ISO 9001:2015

- Environmentally Friendly Production

- Low MOQ Customized Solutions

- Timely Delivery

- Free Expert Consultation

Advantages of BFY Mold's Surface Finishing

Performance Enhancement Metrics

The impact of our surface treatment on injection-molded parts is measured in enhanced performance metrics. Our data reveals a significant increase in the durability, wear resistance, and overall efficiency of molded components subjected to our surface treatment services. This results in parts that not only meet but exceed industry standards.

Environmentally Responsible Practices

Environmental sustainability is a core consideration in our operations. Our surface treatment materials and processes adhere to eco-friendly practices, offering clients the assurance that their injection-molded parts contribute to a greener manufacturing ecosystem.

Client-Centric Collaboration

We recognize the importance of collaboration in achieving the best results. Our client-centric approach ensures that your insights and preferences play a pivotal role in the surface treatment and processing of injection-molded parts. Transparent communication channels facilitate a seamless exchange of ideas, creating a partnership that goes beyond manufacturing.

Different Parts Surface Finishing Services

At our factory specializing in mold design and processing, we take immense pride in showcasing a diverse range of surface finishing solutions that redefine industry standards.

Questions Not Listed Above? Get in Touch!

Surface Finishing Overview

In the dynamic landscape of manufacturing, surface finishing plays a pivotal role in transforming raw components into refined, high-performance products. At our factory specializing in mold design and processing, we offer a comprehensive array of surface finishing solutions designed to enhance not just the aesthetics but also the functionality and durability of each item we produce.

What are the main advantages of Surface Finishing?

1. Precision Polishing:

Meticulous mechanical or chemical processes ensuring a smooth and reflective surface.

Benefits: Enhances visual appeal, facilitates easy cleaning, and promotes a professional finish.

2. Texturing:

Implementation of mechanical or chemical processes to add varied textures to surfaces.

Benefits: Provides tactile feedback, enhances grip, and introduces visual interest.

3. Coating Technologies:

Application of coatings, including paints, films, or specialized finishes, for protection and enhancement.

Benefits: Improves corrosion resistance, durability, and introduces specific properties like anti-scratch or anti-reflective.

4. Anodizing:

Electrochemical process creating an oxide layer on metal surfaces for enhanced durability.

Benefits: Increases corrosion resistance, provides decorative finishes, and maintains material integrity.

5. Plating:

Electroplating or electroless plating processes depositing a thin layer of metal onto surfaces.

Benefits: Enhances conductivity, provides decorative finishes, and improves corrosion resistance.

6. Part Marking:

Techniques employed to mark parts with identification codes, logos, or other information.

Benefits: Enables traceability, branding, and compliance with industry standards.

Applications of Surface Finishing

1. Precision Polishing:

Applications: Ideal for products where aesthetics and surface smoothness are critical, such as consumer electronics and automotive components.

2. Texturing:

Applications: Commonly used in consumer goods, electronics, and automotive interiors for both functional and aesthetic purposes.

3. Coating Technologies:

Applications: Widely applied in automotive parts, appliances, and electronics for functional and protective enhancements.

4. Anodizing:

Applications: Primarily used in aerospace, automotive, and consumer electronics for aluminum components.

5. Plating:

Applications: Widely applied in automotive, electronics, and decorative products for metal finishing.

6. Part Marking:

Applications: Crucial across industries, including automotive, electronics, and medical devices, for product identification and tracking.

Years

Experience

Avoiding Common Injection Molding Defects: Tips for Perfection

Common Defects i...

CNC Machining vs. Injection Molding: Choosing the Right Manufacturing Method

When it comes to...

Reduce Production Costs and Get the Latest Prices Now!