Injection Molding

Plastic injection molding involves the direct injection of plastic material into a specialized mold. After 20 years of relentless experimentation, BFY Mold has honed this method to perfection, providing invaluable support to a multitude of businesses.

20 Years Experienced As A Plastic Molding Company

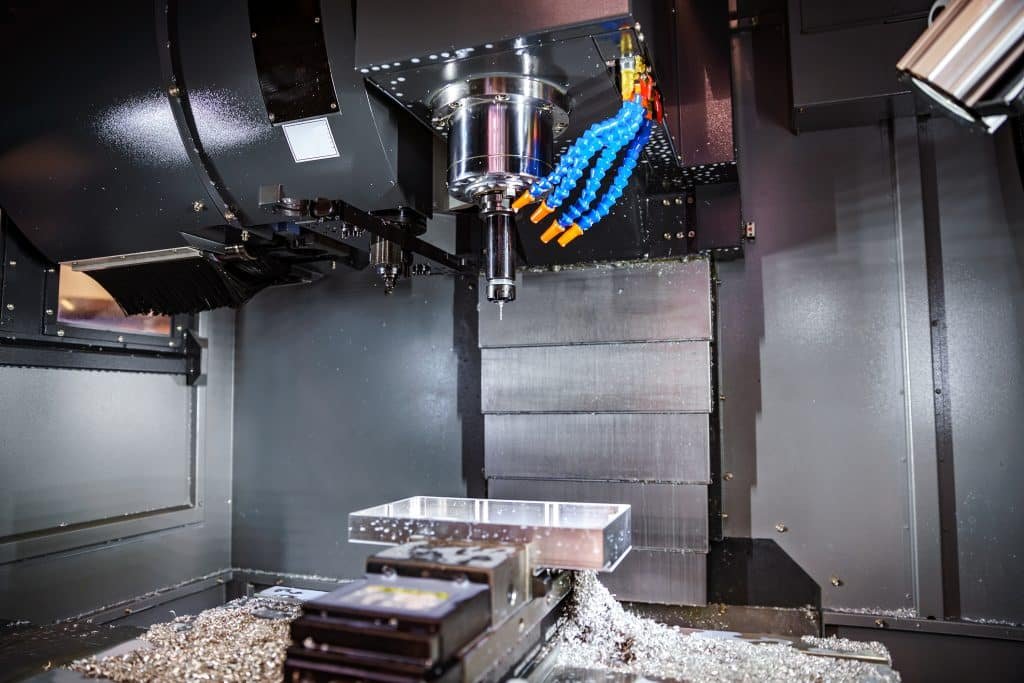

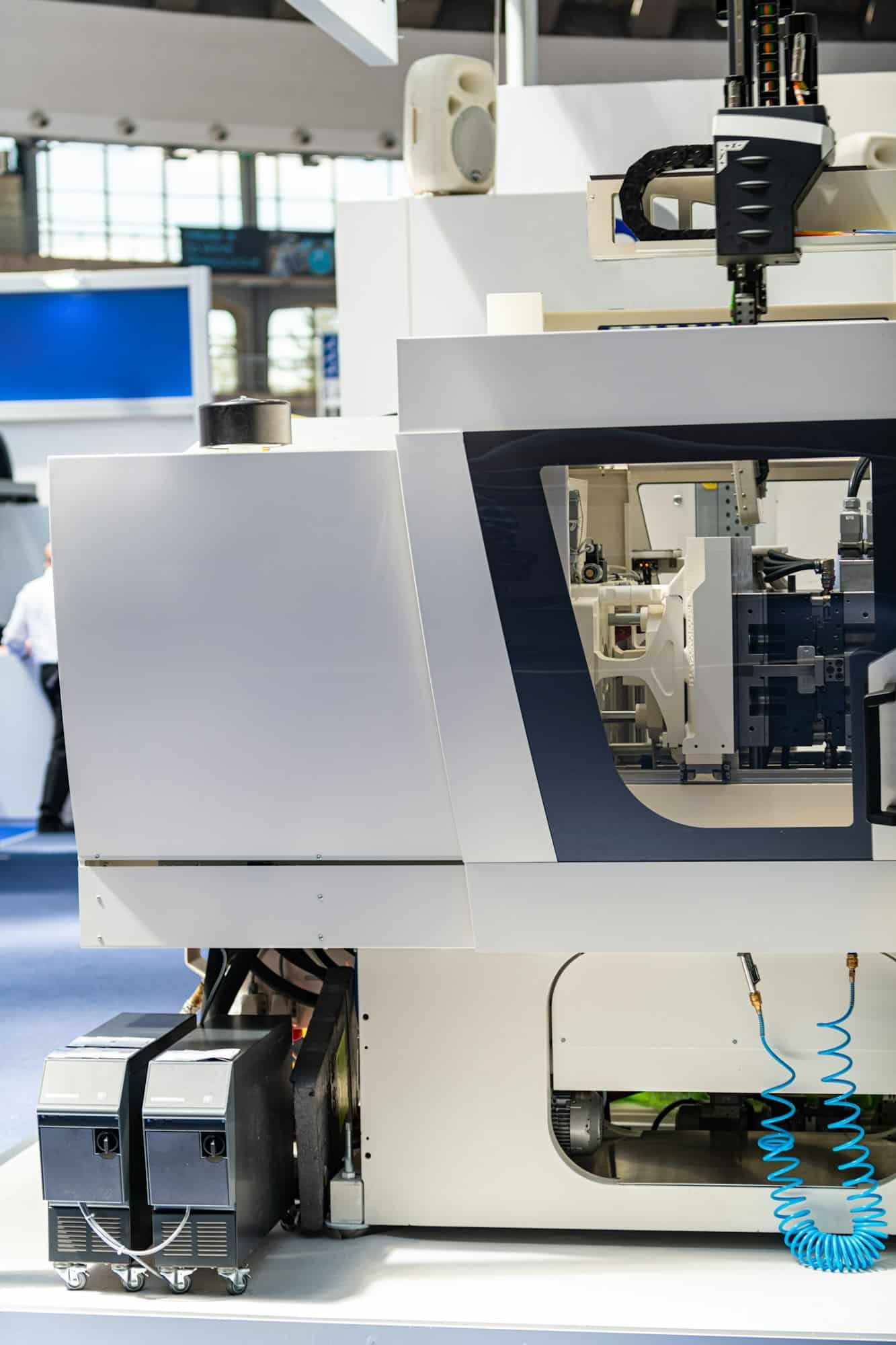

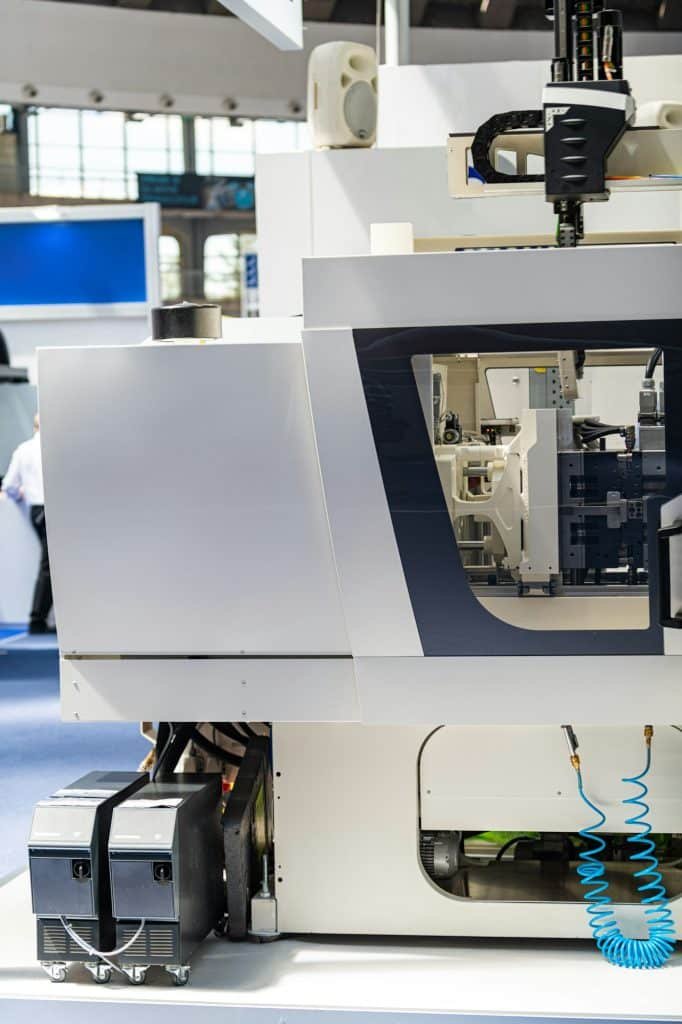

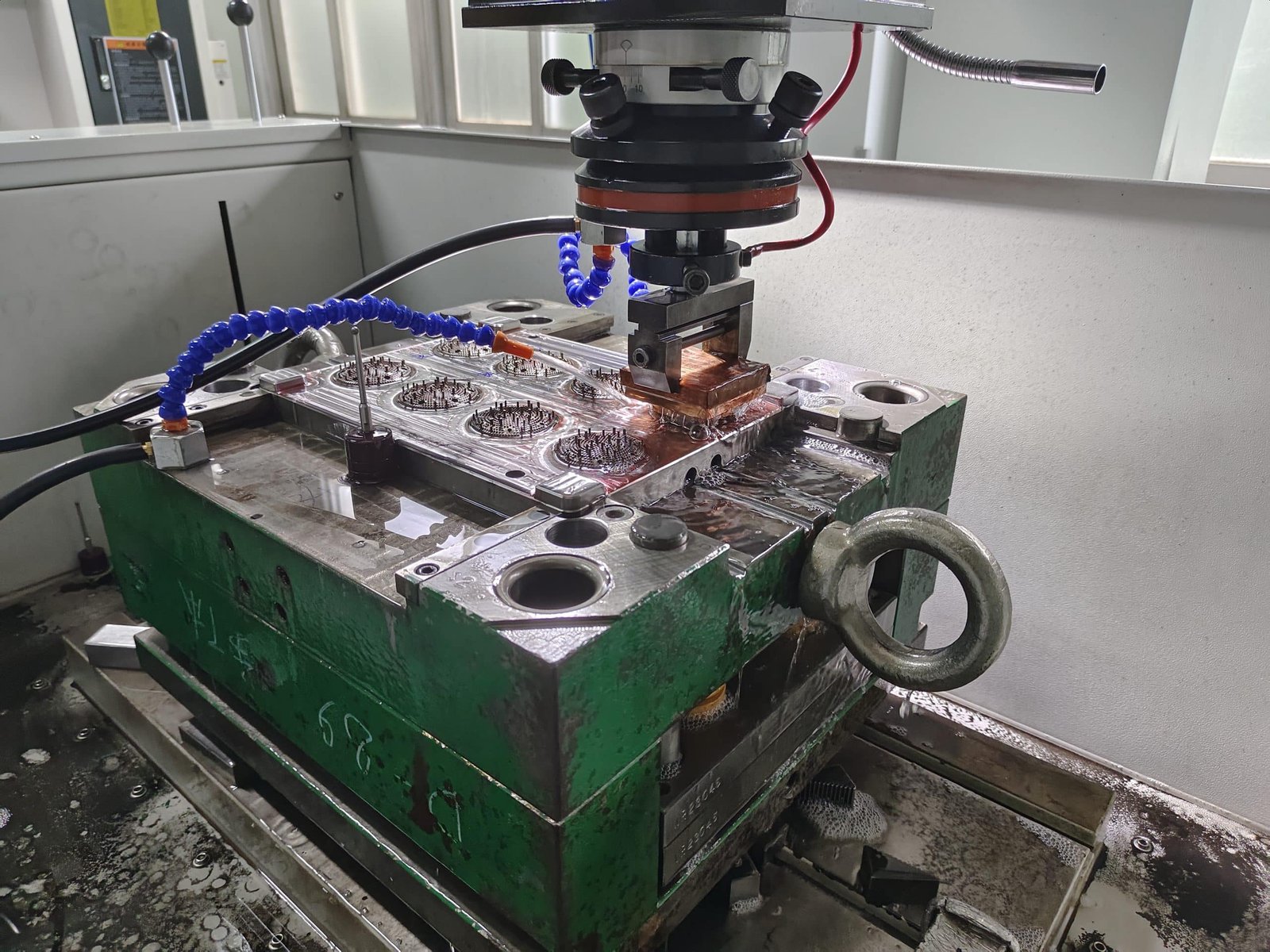

From plastic prototyping to production molding, BFY Mold’s custom mold manufacturing service is your ideal choice for manufacturing high-quality molded parts at competitive prices and with fast lead times. Our state-of-the-art manufacturing facilities house powerful and precise machines, ensuring consistency across all parts produced from the same mold tool.

What sets us apart is our commitment to providing expert consultation at no cost with every injection molding order. This includes advice on mold design, guidance in selecting materials and surface finishes suitable for your specific applications, as well as assistance in choosing the most appropriate shipping methods.

At BFY Mold, we provide a comprehensive range of injection molding services. If you require product design or a prototype for viability testing, we have the expertise to fulfill your needs.

Rest assured, we can deliver precision-made, high-quality molds with turnaround times as short as 10 days. If you’re working against tight deadlines, worry not. Our well-equipped facility boasts numerous injection machines to expedite your orders.

BFY Mold boasts extensive experience with a wide variety of plastic material. We offer a broad material selection and can even source unique alternatives upon client request.

Our Services

Your Precise Plastic Molding Company

- ISO 9001:2015

- Environmentally Friendly Production

- Low MOQ Customized Solutions

- Timely Delivery

- Free Expert Consultation

BFY Mold

Benefits Of China Plastic Injection Molding

Capabilities

Lead Time

Tooling

Mold Cavity Tolerances

Advantages of BFY Mold's Injection Molding

BFY Mold boasts more than two decades of experience in delivering mold manufacturing services to businesses. We seamlessly integrate this extensive know-how with cutting-edge industry technology to provide you with adaptable and budget-friendly injection molding solutions.

Furthermore, our versatile team consists of specialized designers and engineers, allowing us to expertly serve various sectors, including automotive, medical devices, consumer electronics, and new energy industries, to name a few.

Rapid Prototyping

Our rapid prototyping process accelerates part design iterations, offering prompt viability assessment. We offer 3D printing services and CNC machining services to ensure fast delivery of your prototypes to meet the most tight deadlines.

Production Flexibility

Our annual capacity exceeds 600 mold sets. Moreover, BFY Mold has established a trusted network of partners who collaborate with us to expand our production capabilities. Whether it’s a large-scale order or a smaller one, we’re equipped to handle your needs, recognizing that our clients serve various market sizes.

Exemplary Quality

We work with a range of materials sourced exclusively from trusted suppliers. Every step of the process is overseen by seasoned professionals who adhere to our rigorous quality protocols. Parts and prototypes are delivered to our clients only when they meet our exacting quality standards.

Cost-Effectiveness

A single injection mold can produce thousands of parts. Partnering with us not only grants you access to a complete range of cost-effective injection mold services but also eliminates the need for multiple service providers. Our precision and quick turnaround times are additional factors that contribute to keeping your production costs in check.

Exceptional Productivity

BFY Mold can adapt to your specific needs by utilizing multiple injection machines, depending on your order quantity and delivery schedule. Our injection molding expertise guarantees that your plastic parts manufacturing can speed up your time-to-market and align with your customer’s expectations.

Precision Excellence

Rest assured, precision is our top priority as your client. Our CNC machines offer tolerances of approximately +/-0.02mm, while our high-speed CNC models achieve tolerances as tight as +/-0.002mm, aligning perfectly with global industry standards.

How It Works

One-Stop Plastic Injection Molding Service

BFY Mold offers high-precision toolmaking and injection molding services, as well as the use of customized surface finishing, polishing or surface texturing processes.

1. Request Manufacturing

Provide us with your 3D drawings your designs, choose quantity, material and colour options.

2. Quote & DFM

We perform design-for-manufacturability analysis and prepare your quote within 48 hours.

3. Tool Manufacturing

After mold design approval, we start manufacturing the mold.

4. Samples

We produce samples, perform QA, and send the samples to you.

5. Production Completion

When samples are approved, mass production begins.

6. Delivery

Your parts will be delivered to you. Including molds and injection molded parts

Custom Plastic Injection Molding

Visit our extensive gallery featuring a selection of our successfully completed injection molded projects. Gain the assurance that we can tailor your injection molding project to meet your exact specifications.

Home Injection Molding

BFY Mold is your source for all types of injection molding applications for the toy industry. The technology applies to a broad variety of materials and our molds can fabricate a wide range of toys, from plastic trucks to shovels and baby seats.

Medical Device Injection Molding

We are currently working with several medical device companies. Utilizing our advanced injection molding technology, we specialize in the production of a wide range of medical equipment components, including but not limited to surgical instruments, diagnostic device casings, and critical components for healthcare applications.

Automotive Injection Molding

In the past ten years, we have worked with a multitude of companies in the automotive industry. Our range of automotive plastic components includes but is not limited to car bumpers, exterior plastic parts, and brake components, all of which take advantage of our injection molding technology.

Custom Electronics

BFY Mold has a long history of working with a wide range of industries. For example, we specialize in producing plastic parts for household appliances and have worked with many companies in this segment. Using our injection molding technology, millions of electrical appliances have used our technology to create critical elements of their equipment.

Why Choose BFY Mold For Injection Molding?

Among the numerous mold manufacturing companies, BFY Mold stands out as a leader. We bring not only years of experience in the molding industry but also a wide array of distinct advantages. When you choose us, you gain access to premium thermoplastic materials from reputable suppliers. Our streamlined molding process ensures faster production, providing you with comprehensive injection services.

Another key benefit we offer to all clients is significantly reduced molding costs. We prioritize efficiency in our molds, resulting in minimal material waste and cost savings for every product. Our cutting-edge equipment in our Chinese plastic molding facility allows us to meet your specifications down to the finest details. By partnering with BFY Mold, you can be confident in receiving only top-quality products.

Application of Plastic Injection Molding

Comprehensive on-demand production service that guarantees superior precision and quality in all our products. Our advanced production process ensures efficient production rates, enabling us to provide just-in-time delivery for your production parts.

What is Plastic Injection Molding?

Injection molding is a manufacturing process for producing parts by injecting material into a mold. The process starts with heating the material until it melts and shooting it under pressure into a mold. Inside the mold, this material cools and solidifies to form the proper shape. Many items in our everyday lives are produced through injection molding — from small, precise components to larger, complex parts.

What is the process of injection molding?

- Material Preparation: The raw material, usually delivered as tiny pellets, is liquefied.

- Injection: The molten material is injected into a mold at high pressure, filling the mold’s cavities.

- Cooling: The material within the mold cools and solidifies, assuming the desired form.

- Ejection: The mold opens and the product is ejected or removed.

What are the main advantages of injection molding?

- Precision and consistency: Injection molding can achieve very precise and consistent parts with tight tolerances. Such precision is necessary in automotive and medical industries where parts need to comply with exact specifications.

- The multitude of Materials: A variety of materials, colors, and relatively surface finishes can be used, allowing creative and bespoke product design.

- Scalability: Injection molding can scale from low to high production volumes, allowing it to be used for both prototyping and mass production.

- Lead Times: Injection molding can have shorter lead times than some of the alternative manufacturing processes.

Injection Molding Material Options

- PP

- ABS

- PC

- PE

- PA6

- Nylon

- POM

- PVC

- PS

- PMMA

- PLA

Finish Options of Injection Molding

- Mold Texturing

- Custom color-matching

- Threaded inserts

- Pad printing

- Laser engraving

- Basic assembly

- Standard finish

- SPI finish

Years

Experience