Mold Design

We provide custom plastic injection molds to ensure your project is a success. We work with you to understand the characteristics of your project and then develop a precise injection mold design based on your specifications. Our professional technicians handle all the complexities involved in the mold production process. Our versatility allows us to develop prototype tooling and production molds at affordable prices.

20 Years Experienced As A Mold Making Factory

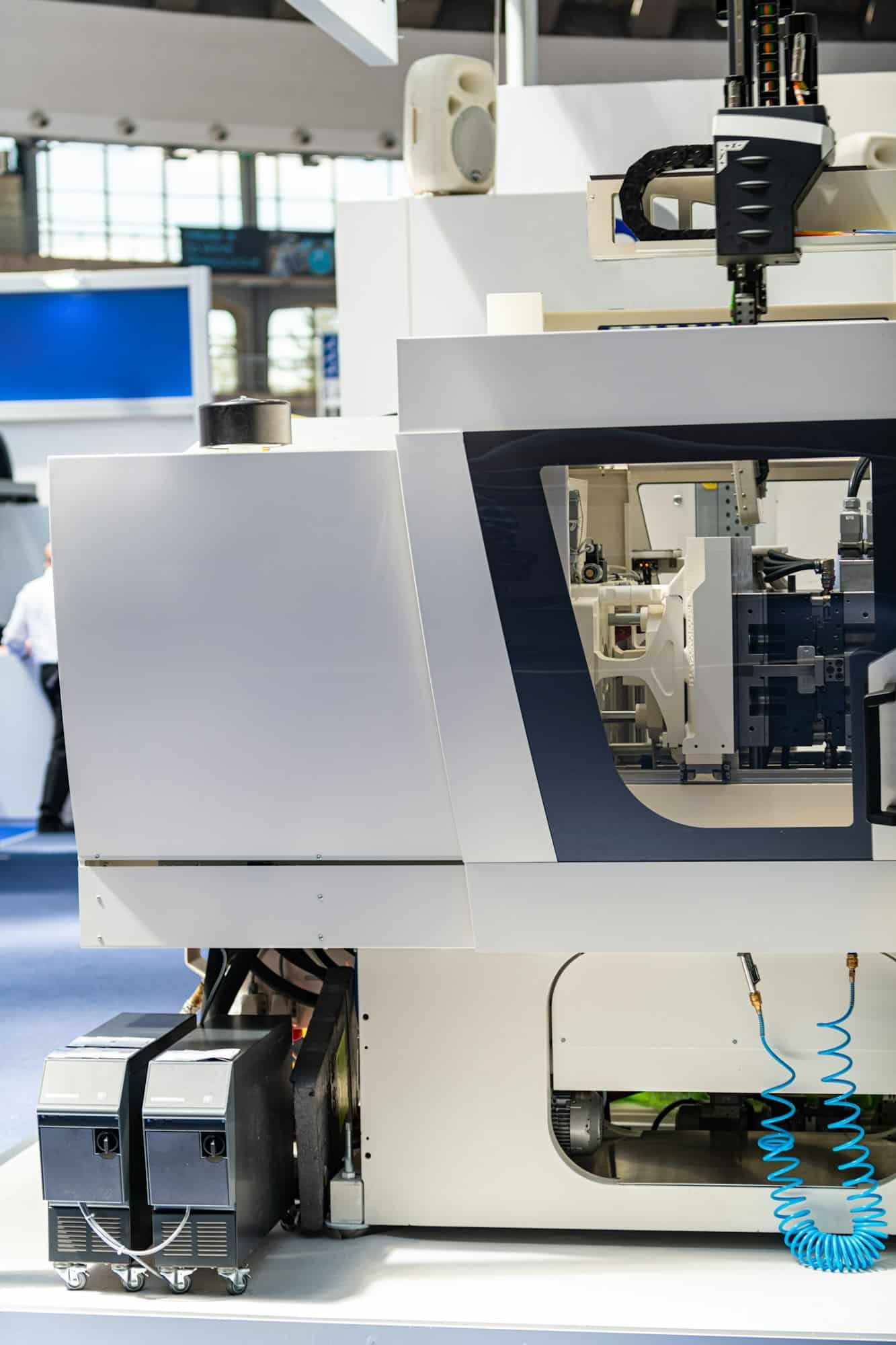

From plastic prototyping to production molding, BFY Mold’s custom mold manufacturing service is your ideal choice for manufacturing high-quality molded parts at competitive prices and with fast lead times. Our state-of-the-art manufacturing facilities house powerful and precise machines, ensuring consistency across all parts produced from the same mold tool.

What sets us apart is our commitment to providing expert consultation at no cost with every injection molding order. This includes advice on mold design, guidance in selecting materials and surface finishes suitable for your specific applications, as well as assistance in choosing the most appropriate shipping methods.

At BFY Mold, we provide a comprehensive range of injection molding services. If you require product design or a prototype for viability testing, we have the expertise to fulfill your needs.

Rest assured, we can deliver precision-made, high-quality molds with turnaround times as short as 10 days. If you’re working against tight deadlines, worry not. Our well-equipped facility boasts numerous injection machines to expedite your orders.

BFY Mold boasts extensive experience with a wide variety of plastic material. We offer a broad material selection and can even source unique alternatives upon client request.

Our Services

Your Precise Plastic Molding Company

- ISO 9001:2015

- Environmentally Friendly Production

- Low MOQ Customized Solutions

- Timely Delivery

- Free Expert Consultation

Overview of Injection Mold Types

From prototype molds to production and export molds, we offer various types of injection molds as per your specifications and applications.

Single Cavity Mold

- A single-cavity mold is a type of injection mold that specifically refers to a design that contains only one molding cavity inside the mold. This type of mold is suitable for producing plastic products of a single shape or size. Single-cavity molds are a flexible and economical choice, especially suitable for scenarios that require small-scale production or have relatively simple product shape requirements.

Multi-cavity Mold

- A multi-cavity mold is a type of injection mold. Compared with a single-cavity mold, it has multiple molding cavities and can produce multiple identical or different plastic products at the same time. It has significant advantages in improving production efficiency, reducing costs, and ensuring product consistency, and is especially suitable for large-scale and high-efficiency injection molding production.

Household Appliance Mold

Since household appliances usually need to operate stably for a long time, household appliance molds usually use highly wear-resistant tool steel or alloy materials to ensure that the mold has sufficient life and stability. In order to improve production efficiency and reduce production costs, some household appliance molds adopt multi-cavity designs to produce multiple identical or different parts at the same time. With the improvement of environmental awareness, some household appliance molds have begun to use environmentally friendly materials to meet the market’s demand for environmentally friendly performance.

Auto Parts Mold

- Auto parts often have complex structures and shapes, so auto parts molds need to be able to cope with these special design requirements. The design of the mold needs to take into account the structural characteristics of the product to ensure that defects do not occur during the molding process and that it can meet the high standards of automotive manufacturing. Since auto parts usually require high strength and durability, auto parts molds usually use high-quality tool steel or special alloy materials to ensure that the mold has sufficient life and stability.

Two-Shot Injection Mold

A Two-Shot Injection Mold, also known as dual-shot, double-shot, or multi-shot mold, is a specialized type of injection mold used in the plastic injection molding process. The primary characteristic of a Two-Shot Injection Mold is its ability to inject two different materials or colors into the same mold during a single cycle. Two-Shot molding is particularly beneficial for parts that would traditionally require multiple components or assembly steps. By molding two materials together, it can eliminate the need for secondary operations and reduce overall manufacturing costs.

Why Choose BFY Mold For Mold Design Services?

BFY Mold applies strict quality standards to every plastic injection mold to ensure the consistency and quality of molded parts. Our experts work with you from prototyping to production to optimize rapid processing of prototypes and production parts. Every step of our mold production reflects our commitment to quality and customer satisfaction.

No Minimum Order Quantity

No minimum order requirements facilitate quick turnaround of plastic molded parts from design to production and support your on-demand molding manufacturing needs by reducing injection molding costs.

Quick Turnaround

With certified domestic factories and strong supply chain systems, we speed up product development cycles and bridge your injection molded parts production as quickly as possible.

Tight Tolerances

As an ISO certified company, our standard tolerances are defined by the ISO 2768 standard. We offer a range of injection mold processing tolerances to meet your requirements. Depending on your design, we can achieve tight tolerances of up to +/-0.02mm.

Professional Technical Support

Extensive expertise in a wide range of molds and products can support your business by providing advice and solutions to achieve your goals.

How It Works

One-Stop Mold Making Service

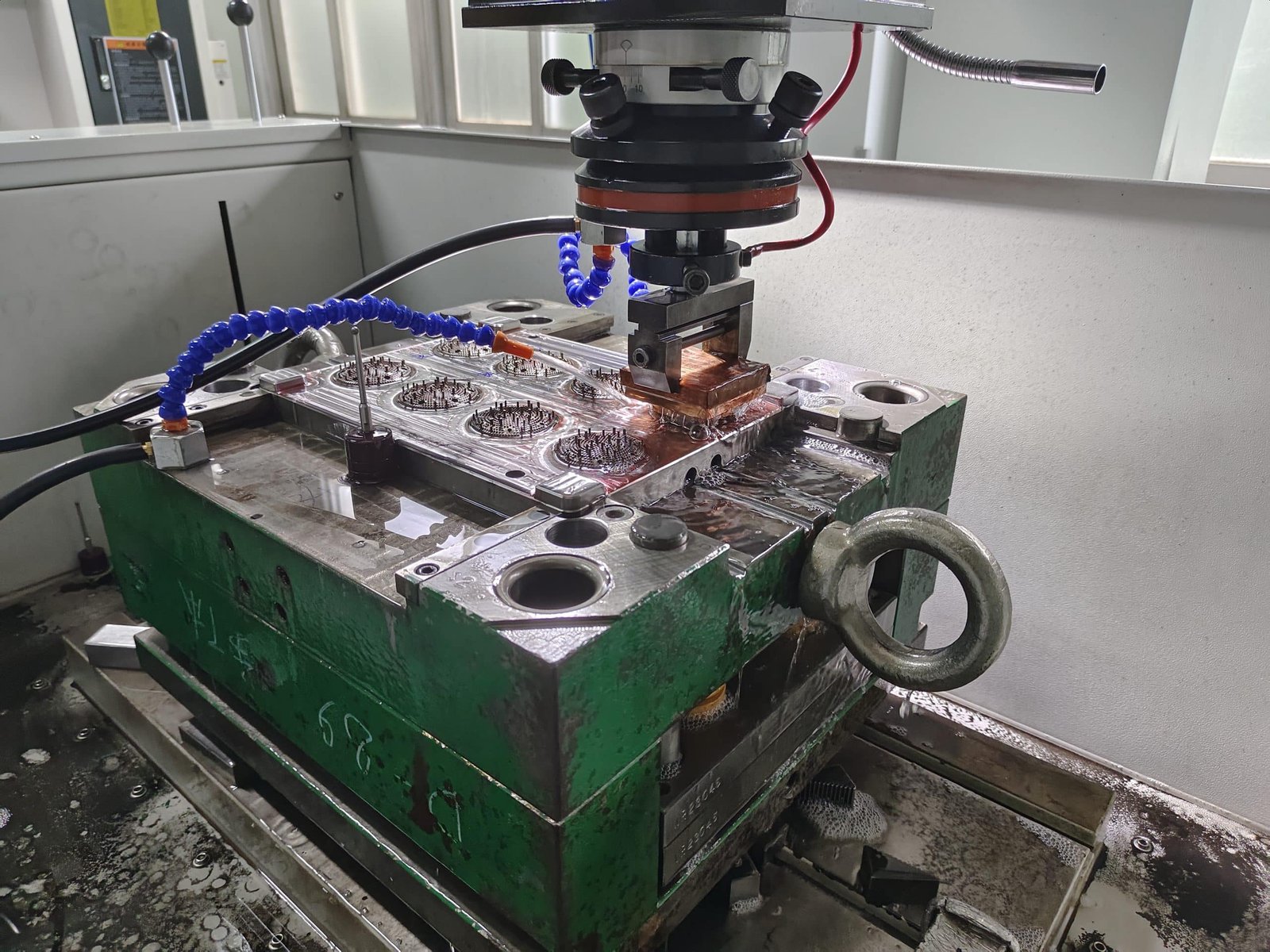

BFY Mold offers high-precision toolmaking and injection molding services, as well as the use of customized surface finishing, polishing or surface texturing processes.

1. Request Manufacturing

Provide us with your 3D drawings your designs, choose quantity, material and colour options.

2. Quote & DFM

We perform design-for-manufacturability analysis and prepare your quote within 48 hours.

3. Tool Manufacturing

After mold design approval, we start manufacturing the mold.

4. Samples

We produce samples, perform QA, and send the samples to you.

5. Production Completion

When samples are approved, mass production begins.

6. Delivery

Your parts will be delivered to you. Including molds and injection molded parts

Custom Plastic Injection Molding

Visit our extensive gallery featuring a selection of our successfully completed injection molded projects. Gain the assurance that we can tailor your injection molding project to meet your exact specifications.

Home Injection Molding

At BFY Mold, we specialize in a diverse range of injection molding applications for the toy industry. Our technology is adaptable to various materials, allowing us to craft an assortment of toy molds, including plastic trucks, shovels, and baby seats.

We have partnered with various companies in the medical device industry. Utilizing our advanced injection molding technology, we specialize in the production of a wide range of medical equipment components, including but not limited to surgical instruments, diagnostic device casings, and critical components for healthcare applications.

Over the last decade, we’ve collaborated with numerous companies in the automotive sector. Leveraging our injection molding technology, we excel in producing a broad spectrum of automobile components, encompassing car bumpers, exterior plastic parts, brake components and so on.

BFY Mold has a rich history of collaboration with diverse industries. Notably, we’ve partnered with numerous companies to produce plastic parts for household appliances. Our injection molding technology has played a pivotal role in crafting critical components for millions of electrical appliances.

Application of Mold Making

Comprehensive on-demand production service that guarantees superior precision and quality in all our products. Our advanced production process ensures efficient production rates, enabling us to provide just-in-time delivery for your production parts.

What is Mold Design?

Mold design refers to the process of creating the blueprint or design for a mold, which will be used to shape a material (usually plastic, metal, or other substances) into a final product. The mold is typically the inverse of the desired product shape and is crafted to accommodate the material’s flow and solidification.

What is the Key Aspects of Mold Design?

- Part Design Analysis:

Understanding the geometry and specifications of the part to ensure the mold will produce it accurately. This includes considering dimensions, tolerances, and the material’s shrinkage upon cooling.

- Material Selection:

Choosing appropriate materials for the mold, considering factors such as wear resistance, thermal conductivity, and the type of material being molded.

- Mold Structure:

Designing the mold components, including the cavity, core, cooling channels, runners, gates, and ejection systems. These elements must work together to allow for efficient material flow, cooling, and part removal.

- Mold Flow Analysis:

Simulating how the material will flow into the mold, identifying potential issues such as air traps, weld lines, or incomplete filling. This analysis helps optimize the design for better quality and efficiency.

- Cooling System Design:

Ensuring the mold has an effective cooling system to quickly and uniformly cool the material, reducing cycle time and improving part quality.

What are the main advantages of injection molding?

1. High Precision and Consistency: Injection molding can produce highly precise and consistent parts with tight tolerances. This precision is crucial in industries like automotive and medical where parts must meet strict specifications.

2. Design Flexibility: It accommodates the use of multiple materials, colors, and surface finishes, enabling creative and customized product designs.

3. Scalability: Injection molding can scale from low to high production volumes, making it suitable for both prototyping and mass production.

4. Short Lead Times: Injection molding can offer shorter lead times compared to some alternative manufacturing methods.

Injection Molding Material Options

- PP

- ABS

- PC

- PE

- PA6

- Nylon

- POM

- PVC

- PS

- PMMA

- PLA

Finish Options of Injection Molding

- Mold Texturing

- Custom color-matching

- Threaded inserts

- Pad printing

- Laser engraving

- Basic assembly

- Standard finish

- SPI finish

Applications of Mold Design

- Automotive: Producing various components, from small gears to large body panels.

- Medical: Creating precise and sterile parts for medical devices.

- Consumer Goods: Manufacturing everyday products like plastic bottles, containers, and household items.

- Electronics: Producing parts for electronic devices, such as casings and connectors.

Years

Experience