Typically, developing a new injection-molded product involves the following steps:

1. Determine the final use requirements of the product

Generally refers to the use of the product environment, bearing requirements, size, appearance requirements, life, etc. For some national standards and industry standards, it should also be considered when determining the use requirements in product design.

2. Structural modeling design

The design of injection molding products, is also preliminary, mainly in the case of detailed consideration of the processing conditions of the structure and appearance design, should try to avoid the side parting core withdrawal, and simplify the release mechanism.

3. Select materials

According to the use requirements of the product, determine the optional material, while considering the product structure according to the performance of the material, redesign its shape, and determine the final material.

4. Improve the design from the point of view of forming process

This step needs to be carried out after the material is determined, because the flow rate, molding shrinkage rate, and so on are different due to different materials and their processing properties are not the same.

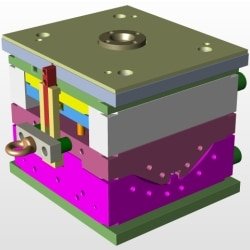

5. Mold manufacturing

The manufacturing of plastic parts is mainly to test the above design, and to further modify the design after a comprehensive evaluation of the processing performance and use performance.

It can be seen from the above steps that the design of injection molded products is a comprehensive process that consists of steps such as modeling design, structural design, and material selection according to the requirements of use.

Among them, these steps intersect and influence each other, and must be measured comprehensively in the design process to get the best design effect. This is the so-called structure and process performance of the relationship that has a deeper understanding, product designers can design the normal production of injection products.

The processing personnel can also identify the defects of some products in production and adjust the injection molding process parameters.

BFY Mold integrates product conception with product forming and mainly undertakes plastic mold product development, mold design and manufacturing, product injection molding, product surface treatment, and other services. With more than 20 years of production experience in mold design and mold manufacturing, the injection molding processing industry can create competitive molds for you. Contact us today for free drawing optimization.