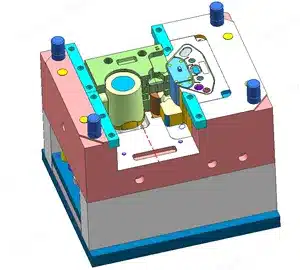

There are two templates on the injection molding machine. One does not move, called a fixed template; The other piece can be moved, called a dynamic template. The mold is fixed to the two templates by screws and pressure plates respectively. When opening the mold, the dynamic template of the injection molding machine moves, thus driving the mold to open.

After the mold is manufactured, it is necessary to carry out injection molding, on the machine, and start to make products. However, there are many models of injection molding machines, and each injection molding machine has its parameters. Mold design must meet the requirements of the injection molding machine model provided by the customer, otherwise, it will not be able to produce.

Injection molding machine design parameters are many, and the following focus on several parameters related to the mold. Let’s learn the specific mold design.

1. Injection Quantity

The injection volume is the maximum mass value (or volume value) that the injection molding machine can shoot the glue at one time during production. It represents the maximum injection molding capacity of this type of injection molding machine. The amount of molten glue used in the mold design is less than the injection molding machine. Otherwise, the product is not satisfied and can not be produced.

2. Clamping Force

The key is the compression force of the injection molding machine on the template when the mold is closed. The clamping force required by the molded product during molding must be less than the rated clamping force of the selected injection molding machine. Otherwise, the melt glue can easily run from the parting surface, resulting in a flash.

3. Pull Rod Spacing

There are four pull rods in the dead Angle of the fixed template and the moving template of the injection molding machine. Their role is to ensure that the injection molding machine has sufficient strength and stiffness, and is responsible for sliding the template. However, it often limits the overall size of the mold, because the mold is installed from the middle of the tie rod.

Mold dimensions can not be greater than they are for the rod spacing, if the length of the mold size has exceeded the rod spacing, then see whether the mold through the rotary lifting into the rod workshop, if the rotary lifting can not be carried out, then only change the mold size, or replace the injection molding machine.

4. Check Nozzle Size

The nozzle head of the injection molding machine is generally spherical. When selecting the gate cover, the spherical radius of the gate cover should be consistent with the spherical radius of the nozzle. To prevent the high-pressure melt from overflowing from the contact gap between the nozzle and the gate cover. The ball radius of the gate cover should be better than that of the nozzle. At the same time, the size of the small end of the main channel should also be slightly larger than the size of the nozzle hole. So the nozzle and the gate sleeve can be easily aligned.