Introduction

In the dynamic world of sports and outdoor activities, the pursuit of excellence knows no bounds. From the adrenaline-fueled arenas of competitive sports to the serene landscapes of outdoor adventures, athletes and enthusiasts alike demand nothing short of the best in performance and durability from their equipment.

At the heart of this quest for perfection lies the transformative power of plastic molds, driving innovation and shaping the future of sports and outdoor gear manufacturing.

The Evolution of Plastic Molds

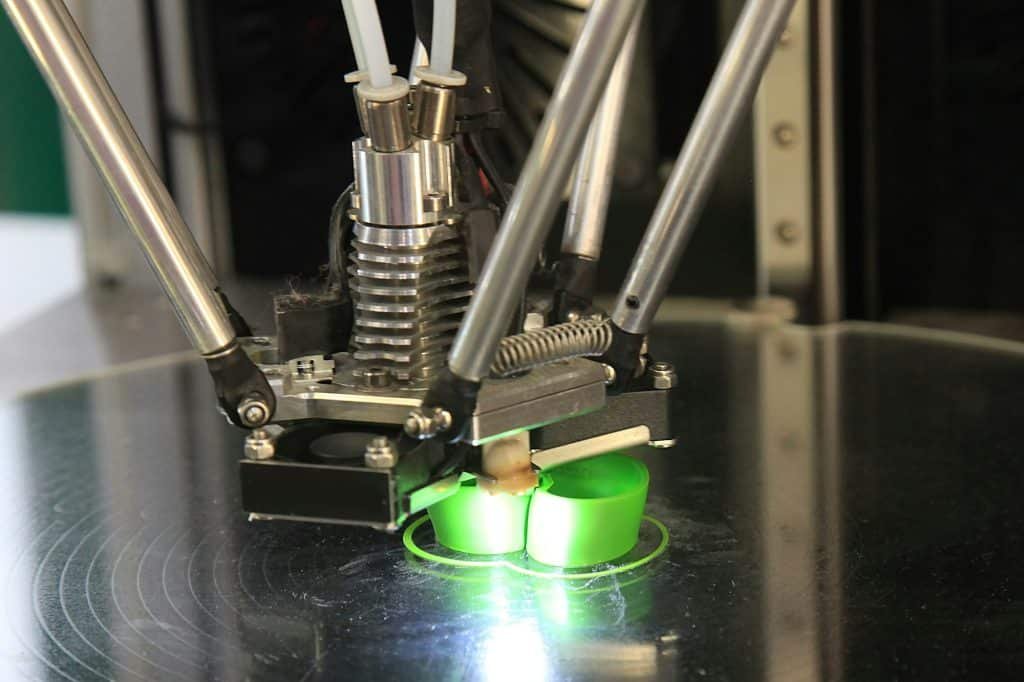

Plastic molding technology has undergone a remarkable evolution, from its humble beginnings as a niche manufacturing process to its current status as a cornerstone of modern production methods.

Injection molding, in particular, has emerged as the preferred choice for producing complex, high-quality components with unparalleled precision and efficiency. This transformative technology has revolutionized the way sports and outdoor equipment are designed, manufactured, and ultimately, experienced by athletes and adventurers around the globe.

Precision Engineering for Performance

In the realm of sports equipment, precision is paramount. Whether it’s a lightweight tennis racket engineered for maximum power and control or an aerodynamic bicycle helmet designed to minimize drag and enhance safety, every aspect of the equipment plays a crucial role in determining performance outcomes.

Plastic molds catalyze innovation, enabling manufacturers to push the boundaries of design and functionality to new heights. Through advanced molding techniques and meticulous attention to detail, manufacturers can create products that not only meet but exceed the exacting standards of athletes and outdoor enthusiasts.

Material Advancements Driving Innovation

Central to the success of plastic molding in the sports and outdoor markets are the advancements in materials science that have expanded the realm of possibilities for designers and engineers. High-performance polymers, reinforced composites, and advanced additives offer unparalleled strength, durability, and versatility, allowing for the creation of products that withstand the rigors of intense athletic competition and extreme outdoor conditions.

Whether it’s a resilient soccer ball that maintains its shape and responsiveness after countless kicks or a rugged hiking boot that provides superior traction and support on rugged terrain, the right choice of materials is essential in delivering the performance and reliability that athletes and adventurers demand.

Innovative Design Solutions

The marriage of precision molding technology with innovative design solutions has yielded a new generation of sports and outdoor equipment that pushes the boundaries of performance and functionality.

From intricate patterns and textures that enhance grip and control to aerodynamic profiles that minimize drag and maximize speed, designers are leveraging the capabilities of plastic molds to unlock new possibilities in product design.

Moreover, the ability to rapidly prototype and iterate designs allows for accelerated innovation cycles, enabling manufacturers to stay ahead of the curve and anticipate the evolving needs of athletes and outdoor enthusiasts.

Meeting the Demands of a Dynamic Market

In today’s fast-paced sports and outdoor markets, agility and adaptability are essential for success.

Plastic molding technology offers manufacturers the flexibility to respond swiftly to changing market demands, whether it’s introducing new product lines, customizing designs to meet individual preferences, or scaling production to meet surges in demand. By leveraging the inherent versatility of injection molding, manufacturers can maintain a competitive edge in a dynamic and ever-evolving landscape.

Conclusion

In conclusion, plastic molds are at the forefront of innovation in the sports and outdoor markets, driving advancements in performance, durability, and design. Through precision engineering, material advancements, and innovative design solutions, manufacturers are pushing the boundaries of what’s possible, delivering products that inspire athletes and adventurers to reach new heights of excellence.

As technology continues to evolve and market demands evolve, the transformative power of plastic molding will continue to shape the future of sports and outdoor equipment manufacturing for years to come.

Keywords: plastic molds, sports equipment, outdoor gear, injection molding technology, high-performance materials, innovative design solutions