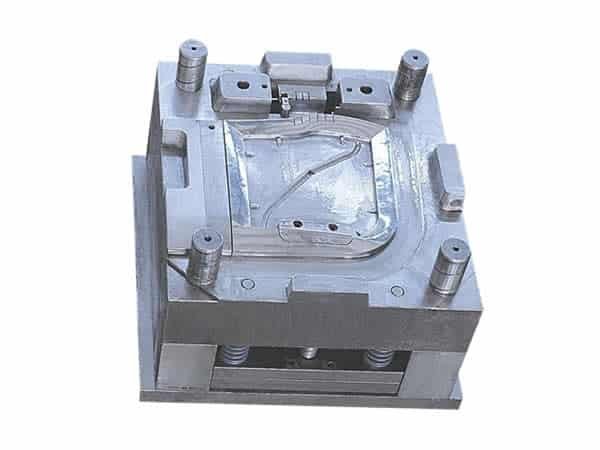

1. The cavity and core are three-dimensional

The internal and external shapes of the plastic parts are directly injection-molded by the cavity and the core of the plastic mold. The shape of the cavity and the core is also the reaction of the plastic parts. These complex three-dimensional shapes are difficult to process, especially the product surface processing in the blind area of the cavity, which is enhanced by the common machine tool. This not only requires high technical level workers, a variety of auxiliary tools to be more, and a long processing cycle.

2. High precision is required

The dimension precision of the cavity and core of modern mold is generally required to be IT8-9, and the dimension precision of the cavity and core of precision mold for plastic parts is required to be IT6-7, a part of the accuracy of IT7-8. In addition, the mold on the size of each mechanism must be very high requirements, to make the mold open and close reliable. So after the development of mold to adopt high-precision mold processing and product measurement means to reduce errors.

3. High surface quality is required

The Surface roughness of modern mold cavity and mold core are generally Ra0.2-0.1 um, and the Surface roughness of mold cavity with mirror light is below Ra0.05 um. To meet the requirements of roughness, the surface of the cavity and core must be polished after fine carving and electrical pulse. But at present most of them are manual grinding and polishing, the manual part of the work accounted for the whole mold about 40%. Precision Mold, most of the mosaic structure, manual about 10%.To improve the service life of the mold, some molding parts also need to be quenched.

4. The demand for tool performance is increasing

Because the performance of die material is better and better, the requirement of tools for die machining is also increasing, some excellent alloy materials and improved tool designs are often used. In addition, to improve the processing efficiency and reduce the loss, but also to re-design and transformation of the tool to meet the fast-paced mold processing requirements.

5. Long process flow and short manufacturing time

The forming part of the plastic mold is composed of a cavity, a core, a slider, an inclined guide column, etc.. Fixed mold and dynamic mold are by the ceiling and cavity, floor and core, and other components of the combination. To ensure the accuracy of the shape and position of the plates, the matching method is needed. Many kinds of work, many processes, and long process flow. As the injection mold is related to product replacement and market speed, generally given the mold manufacturing time is relatively short. Therefore, the requirements of mold manufacturing to minimize manual operation, improve automation, fast and excellent rapid molding