In this article, you will comprehensively understand two-color plastic products from two aspects. The first is its production process characteristics, and the second point is its injection mold form.

Production process characteristics of injection molding two-color products

1. The two-color injection molding machine is composed of two sets of plasticizing injection devices with the same structure and specifications. According to the production method, the nozzle should have a special structure, or be equipped with two component molds with the same structure that can be rotated and transposed.

When injection plasticizing, the melt temperature, injection pressure, injection melt amount and other process parameters in the two injection plasticizing devices must be the same. Minimize the fluctuation difference of process parameters in the two injection plasticizing devices.

2. Compared with ordinary injection molding plastic products, the melting temperature and injection pressure of the two-color plastic products should adopt higher parameter values. The main reason is that the mold flow channel in the two-color injection molding is relatively long, the structure is relatively complex, and the flow resistance of the injection molten material is larger.

3. Two-color injection molding plastic products should choose raw materials with good thermal stability and low melt viscosity to avoid decomposition due to high melt temperature and long residence time in the flow channel. The most widely used plastics are polyolefin resins, polystyrene, and ABS materials.

4. In the injection molding of two-color plastic products, to make two different colors of molten material in the molding can be well fused in the mold, to ensure the molding quality of the injection molding products, higher melting temperature, higher mold temperature, higher injection pressure and injection rate should be used.

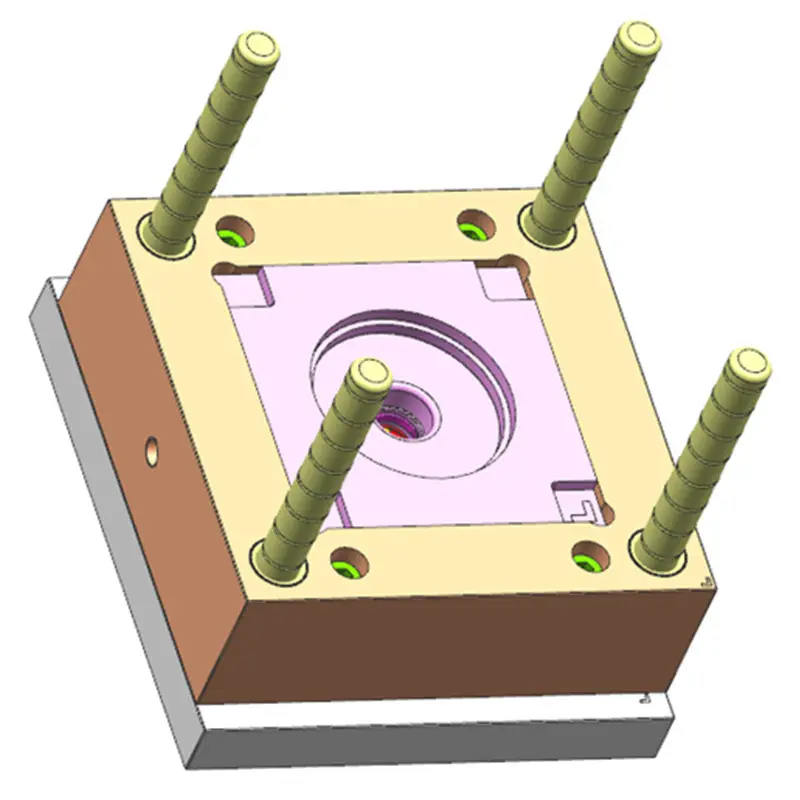

Two-color mold structure form

The traditional two-color injection mold has two forms: “punch translation” and “punch rotation”.

a: The punch translation die has two dips and one punch.

b: When the first cartridge is shot, the punch and the first die are closed. Complete the injection of the first plastic. After the first type of plastic solidifies, the concave and punch are separated, and the semi-finished product formed by the first type of plastic stays in the punch and moves with the punch to the position aligned with the second concave die. After the injection molding machine is closed, the second cylinder is injected with the second plastic. After the second kind of plastic solidifies, the injection molding machine opens the mold and takes out the complete product.

c: The two-color die in the punch rotation form has two concave dies and a rotatable punch consisting of two back-to-back combinations. Double-sided injection molding machine with two cylinders. The second cylinder is proposed to be designed in the vertical direction of the direction of the injection molding machine. Two different plastics can be injected at the same time. When the two types of injected plastic solidify, the injection molding machine opens and automatically ejects the complete product. After removing the product, the “rotatable punch” is turned 180 degrees. The injection molding machine closes and proceeds to the next cycle.

d: Because the punch translation mode of the first and second cylinders are injected in turn. The first and second cylinders of the punch rotation mode are injected simultaneously. Therefore, for the same product, the production efficiency of the punching rotation method is twice that of the punching translation method.