Semiconductor

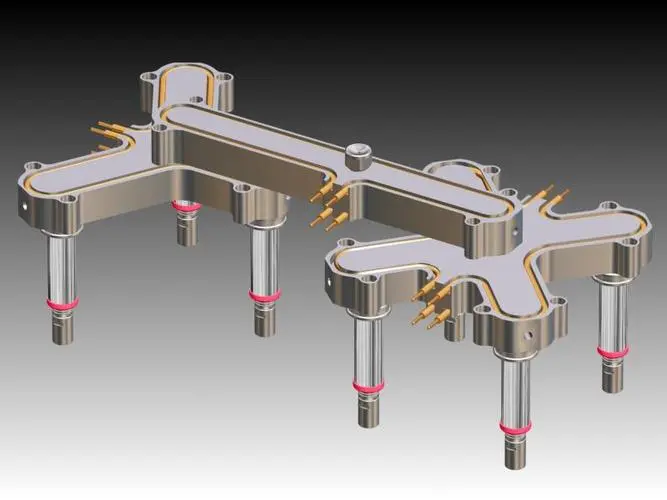

Injection molding plays a critical role in the development of semiconductor by enabling the production of precise prototypes and components rapidly and cost-effectively.

Injection Molding in the Semiconductor Industry

BFY Mold specializes in providing top-tier injection molding, mold design, mirror spark, and CNC machining services, tailored specifically for the semiconductor industry. Our advanced manufacturing techniques and commitment to precision make us a trusted partner for producing high-quality semiconductor components.

Applications of Injection Molding in the Semiconductor Industry

Precision Components:

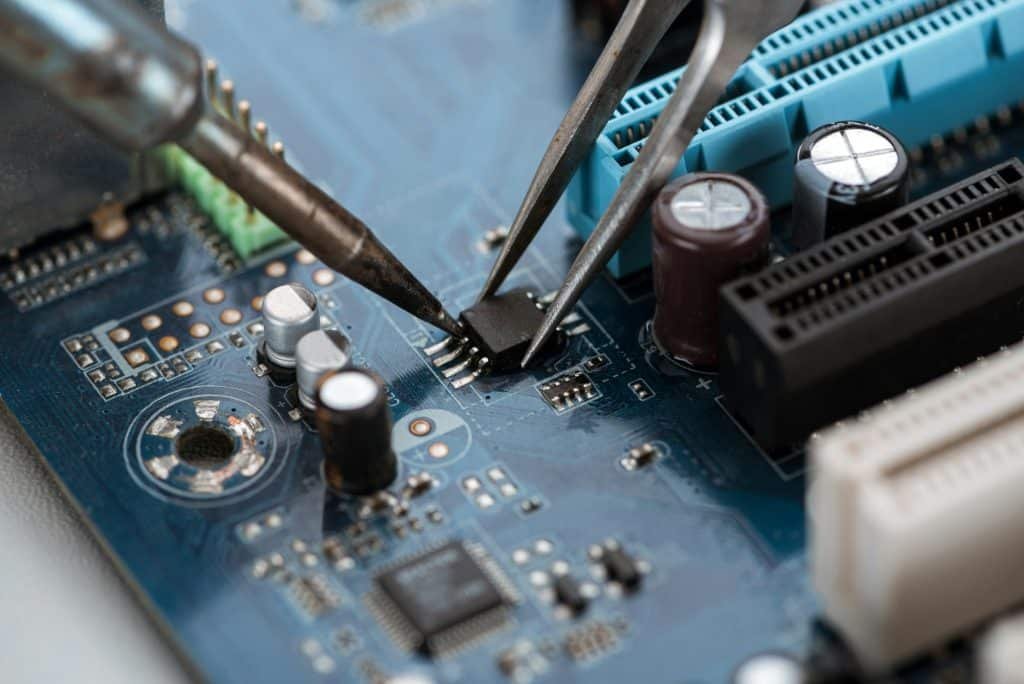

- Connectors: Ensuring reliable electrical connections in semiconductor devices.

- Housings and Casings: Providing protection and structural integrity for sensitive electronic components.

- Chip Carriers: Supporting and protecting semiconductor chips during handling and assembly.

Encapsulation:

Injection molding is used to encapsulate semiconductor devices, protecting them from environmental factors such as moisture, dust, and mechanical damage. Encapsulation ensures the longevity and reliability of semiconductor products.

Custom Parts:

The flexibility of injection molding allows for the creation of custom parts tailored to specific semiconductor applications. This includes components with complex geometries and integrated features that enhance the functionality of semiconductor devices.

Advantages of Injection Molding in the Semiconductor Industry

BFY Mold combines the strengths of injection molding and CNC machining to deliver comprehensive manufacturing solutions for the semiconductor part manufacturing, ensuring that our clients receive the highest quality products.

High Precision and Consistency

Achieves the tight tolerances required for semiconductor components, ensuring perfect fit and function. Consistent production quality is crucial for the reliability of semiconductor devices.

Material Versatility

Utilizes high-performance plastics that offer properties such as thermal stability, chemical resistance, and electrical insulation. Ability to formulate materials to meet specific requirements, enhancing component performance.

Cost Efficiency

Low per-unit cost after mold creation makes it a cost-effective solution for high-volume production.Efficient use of materials minimizes waste and contributes to cost savings.

Plastic Injection Molding For Semiconductor Components

A Comprehensive Guide to Choosing the Right Injection Molding Company

When it comes to producing high-quality plastic parts, choosing the right injection molding company is crucial....

Hot Runner vs Cold Runner Systems: Making Right Choice

Hot Runner vs Cold Runner: How to Choose? When it comes to injection molding, the choice...

7 Key Elements of Injection Mold Costs

When considering the purchase of an injection mold, especially for mass production of plastic parts, it's...