20 Years

Professional ISO Plastic

Injection Molding Company

BFY Mold focuses on the development and production of plastic injection molded products. We assist you in all stages, including mold design and mold making, material selection, and injection molding. The types of quantity include low-volume manufacturing and mass production.

Your ISO Certificated Injection Molding Company

20 years of industry experience

- Shenzhen Baofengyuan Hardware & Plastic Co., LTD., referred to as BFY Mold, was founded in 2010, is committed to innovating traditional manufacturing process, with more than 20 years of industry experience engineers. BFY Mold is a mold injection molding production company that helps wholesalers and brand owners fulfill their products.

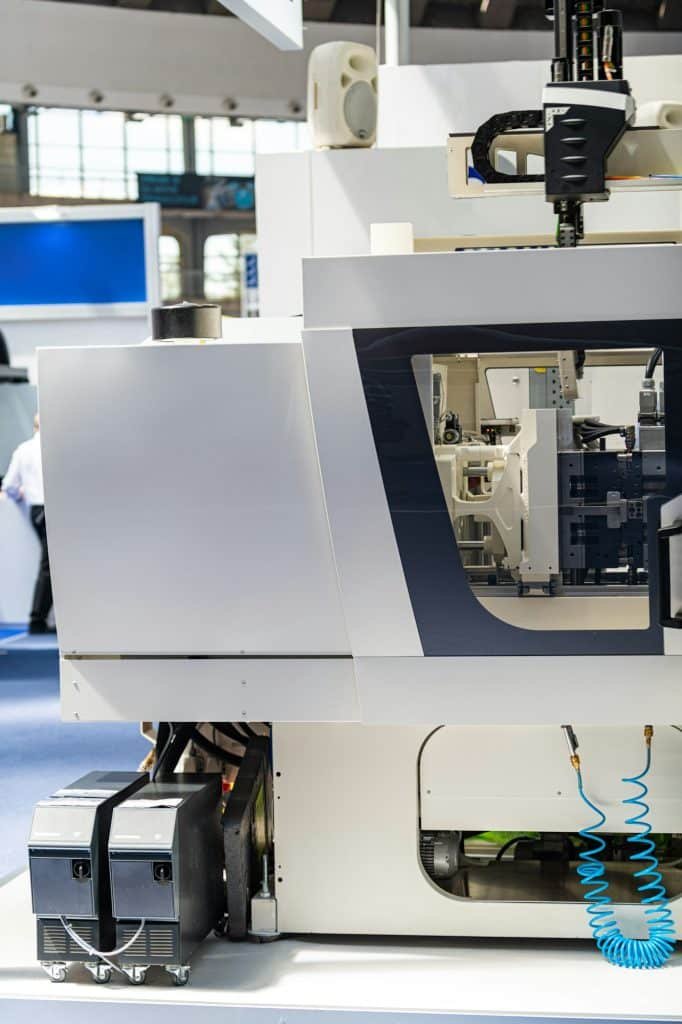

Strong Manufacturing Capabilities

- At the heart of BFY Mold’ s success lies strong manufacturing capabilities. Equipped with senior engineers and advanced machinery, we deliver exceptional precision and efficiency in every project. From CNC Machining, Injection Molding, and Mold Design to Surface Finishing and more, our extensive manufacturing capabilities cover a wide spectrum of industries and applications.

One-stop Services & Solution

- Whether prototyping, low-volume production, or high-volume manufacturing, we offer an extensive range of manufacturing services that cater to diverse requirements. With a team of skilled engineers and state-of-the-art facilities, BFY Mold ensures a seamless transition from concept to final product, saving time, effort, and resources for our clients.

Our injection molding factory churns out hundreds of injection molding parts on demand. We use premium quality materials for every project.

Custom injection molding service for the manufacturing of competitive pricing, high-quality plastic prototyping and production parts in a fast lead time.

CNC machines are very precise and have large tolerances. This service is ideal for prototyping and producing metal, resin and other parts.

High-quality surface finishing services can improve the appearance and functionality of your parts, providing quality metal, composite and plastic surface treatment services.

Services

Strong Molding Capabilities

As a professional injection mold company in China, we provide services from plastic parts & mold design to mold making and molded parts manufacturing. We are capable of bringing injection molded product ideas into reality for a wide range of industries and applications.

BFY Mold takes care of all manufacturing tasks in house thus we are able to offer you an accuracy range within 0.005mm for all molds and well-made injection molded parts.

BFY Mold only uses high-quality metal steel for injection molds and qualified resin for plastic parts. We are happy to provide composition analysis and other necessary test documents.

From raw material inspection and quality control through out the production process, we set up strict standards and make sure that everything undergoes through the quality system.

- Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment (paint, print, water trans-print, welding, assemble).

- Custom made all kinds CNC machining products.

- Custom die casting mold and die casting products, with surface treatment, powder coating, anodizing, etc.

Custom Injection Molding Process

Let us tell you how to make mold design more in line with production efficiency, low cost can also make high quality.

Get Fast Quote

Send us your design by email. Within 1 business day, get a favorable quote and a free design analysis for your prototype and production parts.

Start Production

After you place order, we start the manufacturing process. Besides, we provide 1 to 1 order follow-up service to ensure the quality and cycle of production.

Receive Custom Parts

Once parts pass quality inspections they are well packed for delivery. Rest assured with our 30-day quality guarantee.

After-sales Service

We will continue to follow up with your order, professional engineers to carry out effective after-sales order processing.

Why Choose BFY Mold For Injection Molding?

Among the numerous mold manufacturing companies, BFY Mold stands out as a leader. We bring not only years of experience in the molding industry but also a wide array of distinct advantages. When you choose us, you gain access to premium thermoplastic materials from reputable suppliers. Our streamlined molding process ensures faster production, providing you with comprehensive injection services.

Another key benefit we offer to all clients is significantly reduced molding costs. We prioritize efficiency in our molds, resulting in minimal material waste and cost savings for every product. Our cutting-edge equipment in our Chinese plastic molding facility allows us to meet your specifications down to the finest details. By partnering with BFY Mold, you can be confident in receiving only top-quality products.

BFY Mold

Benefits Of China Plastic Injection Molding

Capabilities

Lead Time

Tooling

Mold Cavity Tolerances

Problem-solver of Your Plastic Injection Molding

Comprehensive on-demand production service that guarantees superior precision and quality in all our products. Our advanced production process ensures efficient production rates, enabling us to provide just-in-time delivery for your production parts.

Questions Not Listed Above? Get in Touch!

Develop a precise plastic injection mold design according to your specifications, our expert technicians handle all complexities involved in the mold production process. Quickly customizing product molds, allows you to quickly test prototype parts and bring them to market faster.

For customers’ common injection molding problems, you can browse this section for a quick understanding.

How can I get a quote?

Send us detailed drawings (STEP/IGS/DWG/PDF/ etc) Or Samples with material, quantity, and surface treatment etc information.

Are you a trading company or a manufacturer?

We are a manufacturer in Shenzhen, China. Our factory’s main business is mold customization, injection molding processing and hardware manufacturing, etc.

What are your processing equipment?

CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine.

Do you have injection machine for mould test?

Yes, we have 90T, 160T, 250T, 320T, 390T, 400T, 450T, 650T, 800T injection machine for mould test and production.

If your mold have problem, how do you solve the problem?

If some spare part broken, we will send you new one. If the mould quality problem, we will repair and pay the ship cost. Or we make another new mould to you free.

Feedback From Plastic Injection Molding Partners

Blogs & Cases

We regularly update articles related to the prototyping and manufacturing industry. Dive deeper into the knowledge with our blog. Learn how to solve problems with powerful injection molding capabilities.