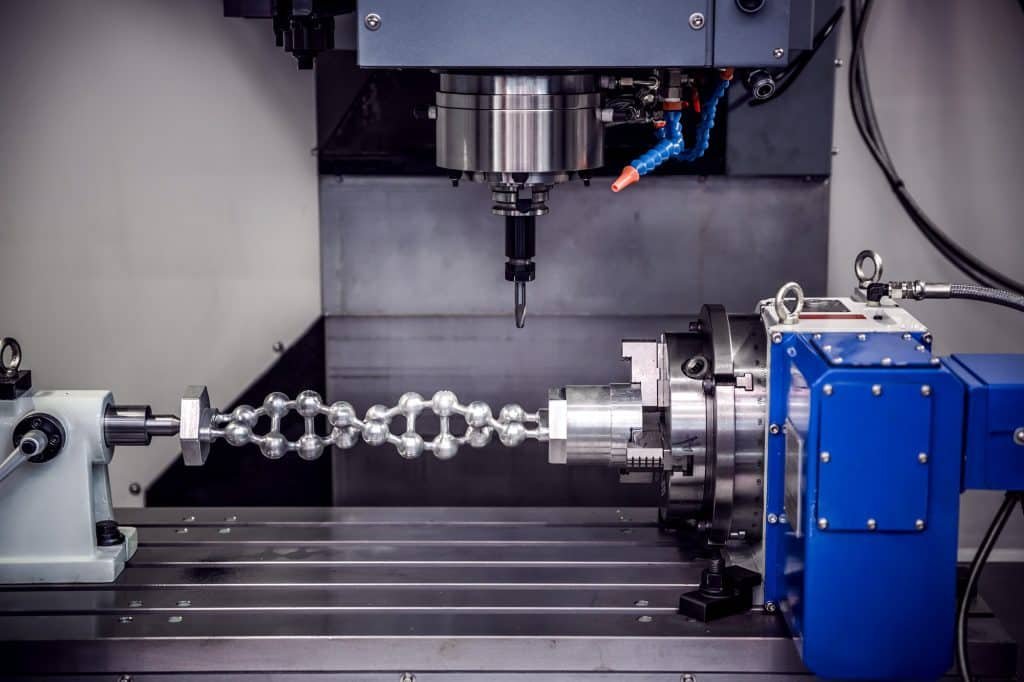

CNC Machining

From prototypes to parts produced on demand, get instant quotes on metal or plastic projects with our CNC machining services. More than 40 kinds of materials, 10 kinds of surface treatment to choose from. ISO 9001:2015 certification.

BFY Mold's CNC Machining Services

BFY Mold’s custom CNC machining services are the solution for engineers, product developers and designers who need prototyping and low-volume production. From simple designs to complex designs with tight tolerances, our ISO 9001 certified CNC machine shop ensures excellence.

Our rapid CNC machining capabilities guarantee high-quality custom machined parts delivered within 1 day.

CNC machines can work with a variety of materials, giving you multiple options for rapid prototyping and production runs of custom, complex parts. We provide instant quotes on over 40 metals and plastics for your manufacturing needs, and you can even compare prices on different processing materials.

Our Services

Your Precise Plastic Molding Company

- ISO 9001:2015

- Environmentally Friendly Production

- Low MOQ Customized Solutions

- Timely Delivery

- Free Expert Consultation

Advantages of BFY Mold's CNC Machining

Fast & Reliable Delivery

BFY Mold has extensive manufacturing capabilities that ensure fast turnaround of CNC machined parts. Plus, with our diverse shipping options, you’ll be able to receive your order on time without the usual hassles.

Professional Engineering Support

No matter where you are, you have access to our 24/7 engineering support year-round. Our experienced engineers can provide the most suitable solution for your part design, material selection, surface finishing and even delivery time.

Consistently High Quality

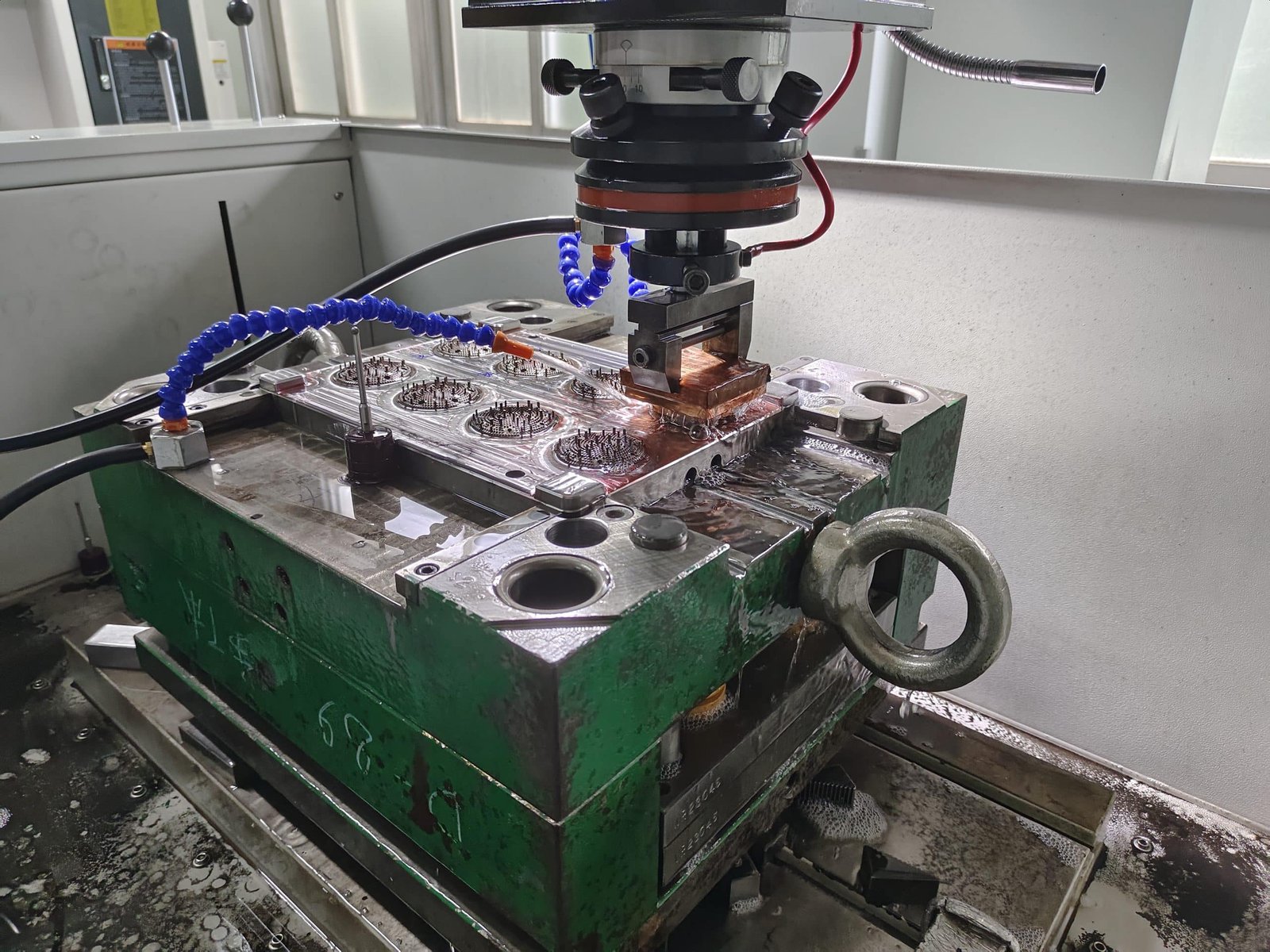

Advanced CNC capabilities, rigorous quality inspections, and ongoing communication ensure that every machined part you receive is of the highest standard, consistent and reliable.

Why Choose BFY Mold For CNC Machining?

Among the numerous mold manufacturing companies, BFY Mold stands out as a leader. We bring not only years of experience in the molding industry but also a wide array of distinct advantages. When you choose us, you gain access to premium thermoplastic materials from reputable suppliers. Our streamlined molding process ensures faster production, providing you with comprehensive injection services.

Another key benefit we offer to all clients is significantly reduced molding costs. We prioritize efficiency in our molds, resulting in minimal material waste and cost savings for every product. Our cutting-edge equipment in our Chinese plastic molding facility allows us to meet your specifications down to the finest details. By partnering with BFY Mold, you can be confident in receiving only top-quality products.

CNC Machining Materials

CNC machines can work with a variety of materials, giving you multiple options for rapid prototyping and production runs of custom, complex parts. We provide instant quotes on over 40 metals and plastics for your manufacturing needs, and you can even compare prices on different processing materials.

Aluminum

Copper

Brass

Stainless Steel

Titanium

Plastic

How It Works

One-Stop CNC Machining Service

BFY Mold offers high-precision toolmaking and injection molding services, as well as the use of customized surface finishing, polishing or surface texturing processes.

1. Request Manufacturing

Provide us with your 3D drawings your designs, choose quantity, material and colour options.

2. Quote & DFM

We perform design-for-manufacturability analysis and prepare your quote within 48 hours.

3. Tool Manufacturing

After mold design approval, we start manufacturing the mold.

4. Samples

We produce samples, perform QA, and send the samples to you.

5. Production Completion

When samples are approved, mass production begins.

6. Delivery

Your parts will be delivered to you. Including molds and injection molded parts

What is CNC Machining?

Computer Numerical Control (CNC) machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece to produce a custom-designed part or product. This process is widely used in various industries for creating precision components with high accuracy and repeatability. Here’s an overview of CNC machining:

What is the Process of CNC Machining?

1. Design:

Create a 3D model of the part using CAD software.

2. Programming:

Generate a CNC program using CAM software, specifying toolpaths, cutting parameters, and other instructions.

3. Setup:

Load the workpiece onto the CNC machine and secure it in place.

Install the necessary cutting tools in the machine.

4. Execution:

Run the CNC program, and the machine will automatically move the tools to cut the material according to the programmed instructions.

5. Quality Control:

Inspect the machined part to ensure it meets the required specifications.

What are the Main Advantages of CNC Machining?

1. Precision and Accuracy:

CNC machining allows for highly precise and accurate production of complex parts.

2. Repeatability:

Once a program is developed, the same part can be reproduced consistently.

3. Versatility:

CNC machines can be used to produce a wide range of parts in various materials.

4. Efficiency:

CNC machining is generally faster and more efficient than manual machining processes.

5. Complex Geometries:

CNC machines can handle intricate shapes and complex geometries that may be challenging for manual methods.

CNC Machining Material Options

- Aluminum

- Stainless Steel

- Brass

- Copper

- Plastics (e.g., Acrylic, Delrin, Nylon):

- Titanium

- Carbon Steel

- Bronze

Finish Options of CNC Machining

Anodizing:

An electrochemical process that creates a protective oxide layer on the surface of aluminum.

Improves corrosion resistance and provides a decorative finish.

Available in various colors.

Polishing:

Mechanical polishing processes, such as abrasive polishing or buffing, create a smooth, shiny surface.

Commonly used for stainless steel and other metals.

Can range from a satin finish to a mirror-like finish.

Painting or Powder Coating:

A layer of paint or powdered pigment is applied to the surface.

Provides corrosion resistance, durability, and aesthetic options.

Common in automotive and consumer electronics.

Electroplating:

A thin layer of metal is deposited onto the surface through an electrochemical process.

Enhances corrosion resistance and provides a decorative finish.

Common plating metals include nickel, chrome, and gold.

Passivation:

A chemical process that removes free iron and contaminants from the surface of stainless steel.

Improves corrosion resistance.

Common in medical and aerospace applications.

Tumbling or Vibratory Finishing:

Parts are placed in a tumbler or vibratory bowl with abrasive media.

Creates a smoother surface and helps remove burrs.

Suitable for small, intricate parts.

Applications of CNC Machining

CNC machining has revolutionized manufacturing by providing a highly efficient and accurate method for producing a wide range of parts across various industries.

- Automotive Industry:

Production of engine components, gears, and other precision parts. - Aerospace Industry:

Manufacturing of aircraft components with tight tolerances. - Medical Industry:

Production of medical implants and devices. - Electronics:

Creation of circuit boards and electronic components. - Prototyping:

Rapid prototyping for product development.

Years

Experience