ABS Injection Molding

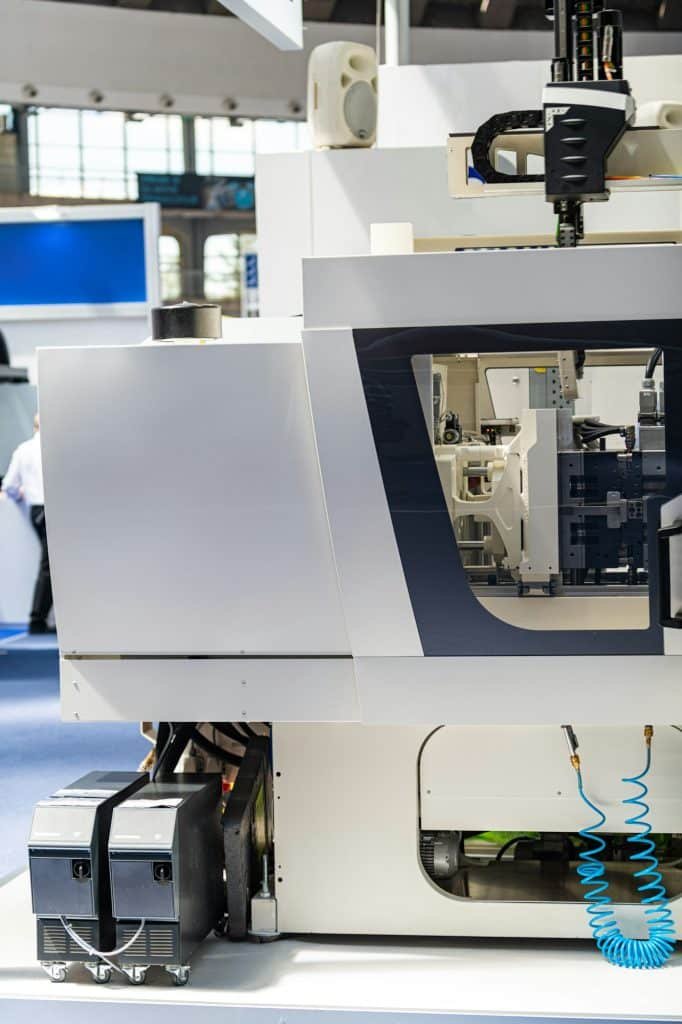

BFY Mold specializes in providing high-quality ABS injection molding solutions, offering precise manufacturing, complex geometries, and efficient mass production to meet diverse industry needs.

ABS Injection Molding Services

BFY Mold’s ABS injection molding services provide you with high-quality, durable parts tailored to your exact specifications, ensuring reliable performance and cost efficiency for your projects.

- High-Tech ABS Molding for Detailed Designs

- Custom ABS Solutions to Your Standards

- Fast-Track ABS from Concept to Production

- Crafting Perfect ABS Parts

Tailored solutions for diverse industries

Sector-Specific Expertise

Specialized materials for optimal performance

Custom Material Solutions

Precision molding with high-quality finishes

Mold, Finish, & Quality

Precision ABS Molding Solution By BFY Mold

At BFY Mold, we specialize in precision ABS molding solutions that cater to your unique project requirements. Our advanced technology and expertise ensure that each part is manufactured with the highest level of accuracy, durability, and consistency, making us the ideal partner for your molding needs.

Whether you need complex geometries, tight tolerances, or high-volume production, our team is dedicated to delivering high-quality ABS parts that meet your exact specifications.

Trust BFY Mold to provide reliable, cost-effective solutions that help you bring your ideas to life with speed and precision.

Advantages of ABS Materials Injection Molding

ABS injection molding offers several key advantages that make it a preferred choice for various applications. Here are six benefits:

Excellent Dimensional Stability

ABS maintains its shape and dimensions even under stress, ensuring precise and consistent parts with minimal warping or deformation.

Ease of Processing

ABS material is known for its ease of molding, allowing for efficient production and the ability to create complex geometries with high accuracy.

Versatility

ABS material can be easily customized with various additives to enhance properties like UV resistance, color, or flame retardancy, making it versatile for diverse applications.

Cost-Effective Production

The efficiency of ABS injection molding reduces material waste and production costs, making it a cost-effective option for both small and large runs.

Good Surface Finish

ABS material provides a smooth surface finish, which can be easily enhanced through post-processing techniques, resulting in aesthetically pleasing parts.

High Impact Resistance

ABS parts are highly resistant to impact, making them durable and ideal for applications requiring toughness and resilience

How We Works

One-Stop Plastic Injection Molding Service

BFY Mold offers high-precision toolmaking and injection molding services, as well as the use of customized surface finishing, polishing or surface texturing processes.

1. Request Manufacturing

Provide us with your 3D drawings your designs, choose quantity, material and colour options.

2. Quote & DFM

We perform design-for-manufacturability analysis and prepare your quote within 48 hours.

3. Tool Manufacturing

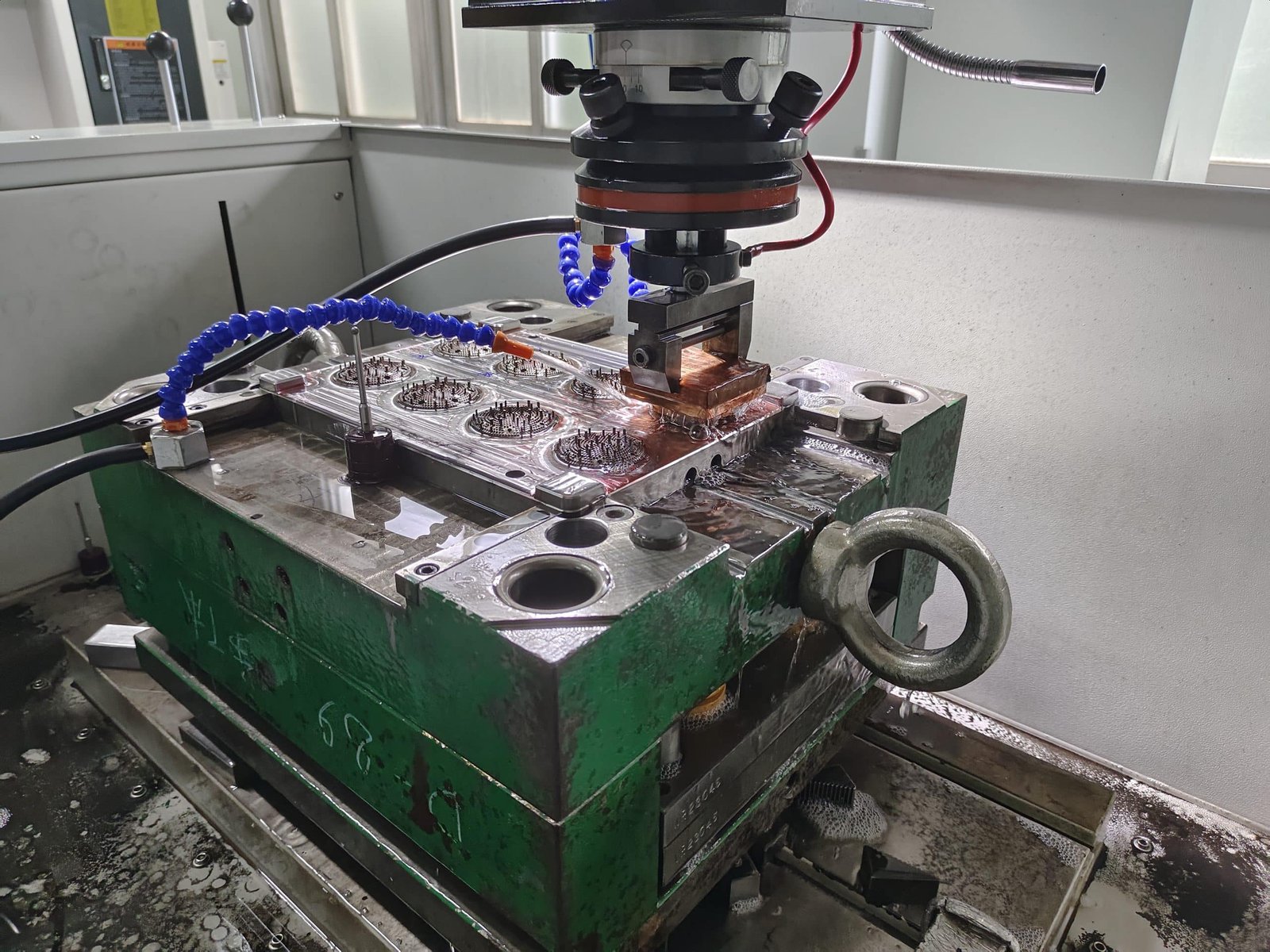

After mold design approval, we start manufacturing the mold.

4. Samples

We produce samples, perform QA, and send the samples to you.

5. Production Completion

When samples are approved, mass production begins.

6. Delivery

Your parts will be delivered to you. Including molds and injection molded parts

Custom Plastic Injection Molding

Visit our extensive gallery featuring a selection of our successfully completed injection molded projects. Gain the assurance that we can tailor your injection molding project to meet your exact specifications.

Home Injection Molding

At BFY Mold, we specialize in a diverse range of injection molding applications for the toy industry. Our technology is adaptable to various materials, allowing us to craft an assortment of toy molds, including plastic trucks, shovels, and baby seats.

Medical Device Injection Molding

We have partnered with various companies in the medical device industry. Utilizing our advanced injection molding technology, we specialize in the production of a wide range of medical equipment components, including but not limited to surgical instruments, diagnostic device casings, and critical components for healthcare applications.

Automotive Injection Molding

Over the last decade, we’ve collaborated with numerous companies in the automotive sector. Leveraging our injection molding technology, we excel in producing a broad spectrum of automobile components, encompassing car bumpers, exterior plastic parts, brake components and so on.

Custom Electronics

BFY Mold has a rich history of collaboration with diverse industries. Notably, we’ve partnered with numerous companies to produce plastic parts for household appliances. Our injection molding technology has played a pivotal role in crafting critical components for millions of electrical appliances.

Why Choose BFY Mold For Injection Molding?

Among the numerous mold manufacturing companies, BFY Mold stands out as a leader. We bring not only years of experience in the molding industry but also a wide array of distinct advantages. When you choose us, you gain access to premium thermoplastic materials from reputable suppliers. Our streamlined molding process ensures faster production, providing you with comprehensive injection services.

Another key benefit we offer to all clients is significantly reduced molding costs. We prioritize efficiency in our molds, resulting in minimal material waste and cost savings for every product. Our cutting-edge equipment in our Chinese plastic molding facility allows us to meet your specifications down to the finest details. By partnering with BFY Mold, you can be confident in receiving only top-quality products.

Application of Plastic Injection Molding

Comprehensive on-demand production service that guarantees superior precision and quality in all our products. Our advanced production process ensures efficient production rates, enabling us to provide just-in-time delivery for your production parts.

What is Plastic Injection Molding?

Injection molding is a manufacturing process used to produce parts and products by injecting molten material (typically plastic) into a mold cavity. The process begins with the material being heated to a liquid state and then forced into a mold under pressure. Once inside the mold, the material cools and solidifies, taking the shape of the mold cavity. Injection molding is commonly used for producing a wide range of items, from small precision components to larger, more complex parts.

What is the process of injection molding?

1. Material Preparation: The raw material, often in the form of small pellets, is melted to a liquid state.

2. Injection: The molten material is injected into a mold under high pressure, filling the mold’s cavities.

3. Cooling: The material inside the mold cools and solidifies, taking on the desired shape.

4. Ejection: The mold opens, and the finished product is ejected or removed.

What are the main advantages of injection molding?

1. High Precision and Consistency: Injection molding can produce highly precise and consistent parts with tight tolerances. This precision is crucial in industries like automotive and medical where parts must meet strict specifications.

2. Design Flexibility: It accommodates the use of multiple materials, colors, and surface finishes, enabling creative and customized product designs.

3. Scalability: Injection molding can scale from low to high production volumes, making it suitable for both prototyping and mass production.

4. Short Lead Times: Injection molding can offer shorter lead times compared to some alternative manufacturing methods.

Injection Molding Material Options

- PP

- ABS

- PC

- PE

- PA6

- Nylon

- POM

- PVC

- PS

- PMMA

- PLA

Finish Options of Injection Molding

- Mold Texturing

- Custom color-matching

- Threaded inserts

- Pad printing

- Laser engraving

- Basic assembly

- Standard finish

- SPI finish

Years

Experience