Low Volume Manufacturing

At BFY Mold, our low-volume manufacturing service is designed to provide cost-effective molding solutions tailored to meet the rising demands of the market.

Low Volume Manufacturing by BFY Mold

Choosing BFY Mold for your low-volume manufacturing needs means partnering with a company that values quality, efficiency, and customer satisfaction. With our state-of-the-art facility and dedicated team, we are committed to delivering the best solutions tailored to your specific requirements.

What is Low-Volume Manufacturing?

Low-volume manufacturing is a specialized production approach designed to meet the needs of businesses requiring smaller quantities of parts or products, typically ranging from a few hundred to several thousand units. This method allows companies to transition from prototypes to market-ready products without the heavy upfront costs associated with large-scale manufacturing.

Advantages of Low-Volume Manufacturing

Cost-Effectiveness

Low-volume manufacturing significantly reduces overhead costs compared to traditional mass production. By optimizing processes and materials, we provide affordable solutions that do not compromise on quality.

Speed to Market

With reduced production times and streamlined processes, low-volume manufacturing enables faster delivery of products. This is crucial for companies looking to respond quickly to market demands or testing new products.

Flexibility

Our low-volume manufacturing services offer the flexibility to accommodate changes in design and production schedules. This adaptability is vital for businesses facing fluctuating market needs or evolving product specifications.

Quality Assurance

At BFY Mold, we maintain rigorous quality control standards, ensuring that every product meets your specifications. Our focus on quality guarantees that even small production runs maintain high standards.

Our Low-Volume Manufacturing Process

The low-volume manufacturing process at BFY Mold is designed to efficiently produce smaller quantities of custom parts.

Initial Consultation

We begin with a thorough consultation to understand your project’s requirements, budget, and timeline.

Design Optimization

Our engineering team collaborates with you to optimize the product design for manufacturability, focusing on simplifying structures and selecting appropriate materials.

Prototyping

We produce prototypes for testing and validation, allowing for any necessary adjustments before moving to full production.

Production

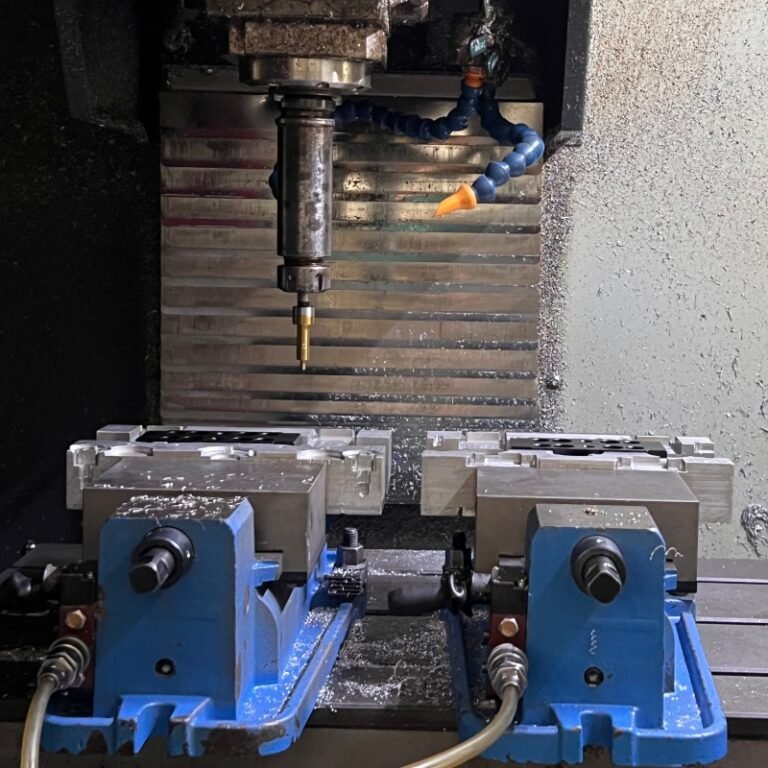

Utilizing advanced manufacturing techniques such as injection molding, CNC machining, and 3D printing, we efficiently produce the required quantities while ensuring high quality.

Delivery and Support

Once production is complete, we ensure timely delivery of your products. Our team remains available for any post-production support or adjustments you may need.

Why Choose BFY Mold For Low-Volume Manufacturing Services?

Transparent Quotations Within 24 Hours

We offer transparent, blind-free quotations for every project within 24 hours. Our detailed cost breakdown allows you to clearly understand the expenses involved, empowering you to make informed decisions.

Design for Manufacturing Expertise

Our experienced team focuses on simplifying and optimizing your product design for manufacturability. Our goal is to enhance your product while reducing costs, ensuring a smoother production process.

Flexible, Customer-Centric Services

We pride ourselves on our flexibility and responsiveness to your unique needs. Whether you require extremely low volumes, urgent order fulfillment, or design modifications, our team is dedicated to resolving challenges and delivering solutions that meet your specifications.

Proven Success

Since our inception, BFY Mold has successfully supported over 300 clients in bringing their products to market. We have a proven track record of excellence, backed by positive feedback from satisfied customers.

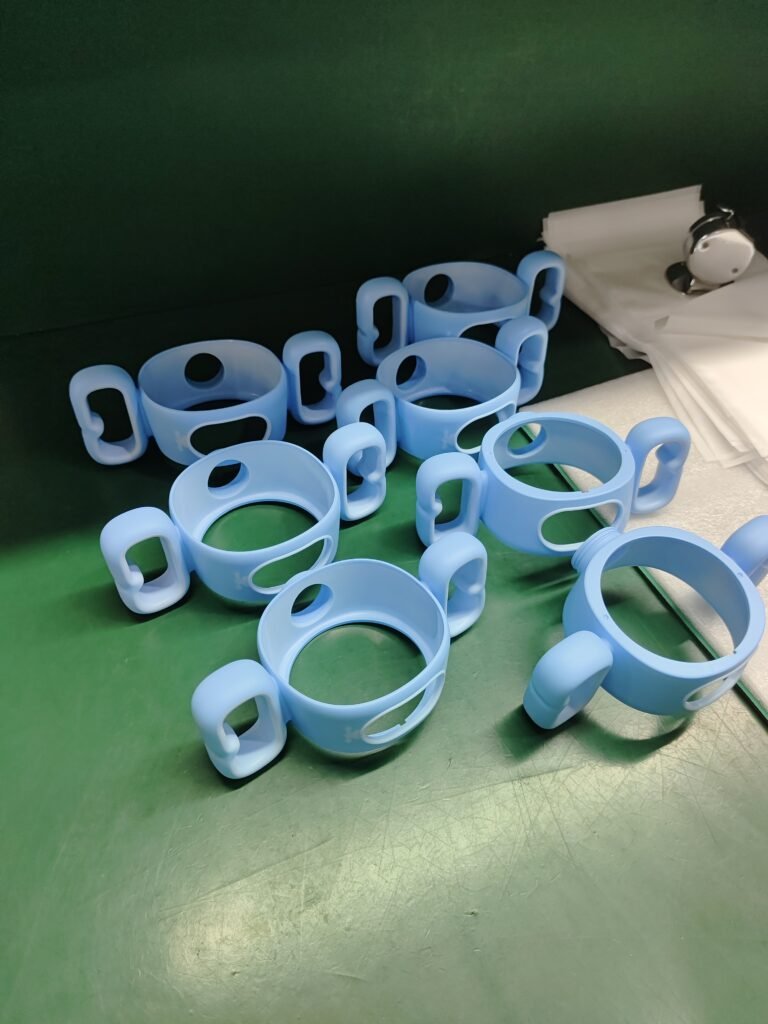

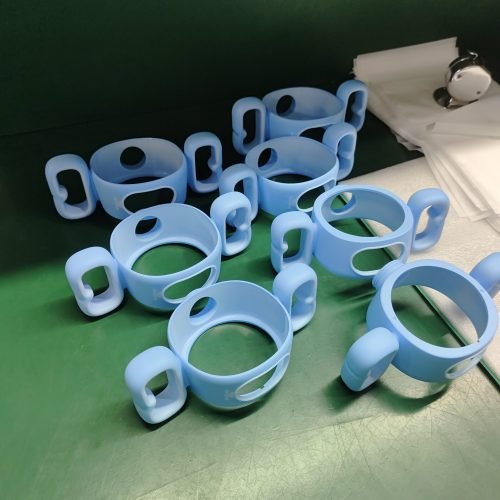

Low-Volume Manufacturing Products

How It Works

Low-Volume Manufacturing Service

At BFY Mold, we offer low-volume manufacturing solutions tailored to meet your specific needs.

1. Request Manufacturing

Provide us with your 3D drawings your designs, choose quantity, material and colour options.

2. Quote & DFM

We perform design-for-manufacturability analysis and prepare your quote within 48 hours.

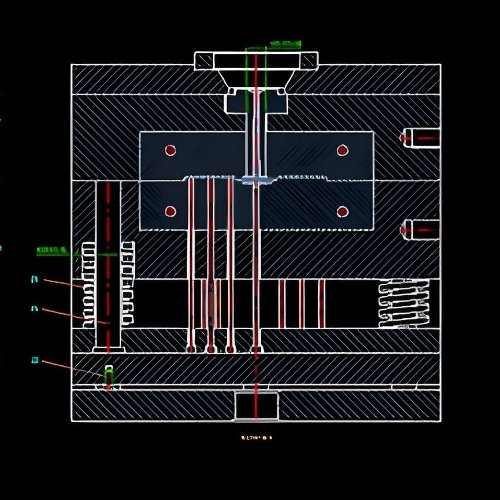

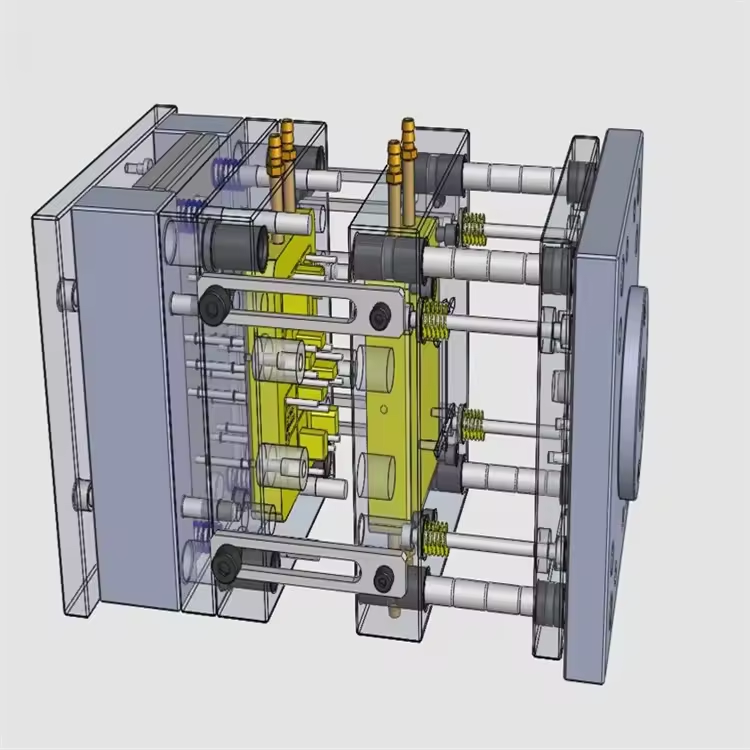

3. Tool Manufacturing

After mold design approval, we start manufacturing the mold.

4. Samples

We produce samples, perform QA, and send the samples to you.

5. Production Completion

When samples are approved, mass production begins.

6. Delivery

Your parts will be delivered to you. Including molds and injection molded parts