In today’s increasingly competitive market in the consumer electronics industry, the manufacturing of components and mold development has become one of the decisive factors in product quality. To meet the market demand for high-precision and high-performance electronic products, enterprises need to invest a lot of energy in mold research development and design. This article will explore the various aspects of mold development for consumer electronics meta accessories, providing a comprehensive guide for readers who want to gain an in-depth understanding of the process.

First, mold development is a complex and fine process, including market research, design, material selection, processing, assembly, testing, and other stages. Different electronic components have different requirements for the mold, which requires personalized design and adjustment in the mold development process.

Market Research & Demand Analysis

Market research is the first step of mold development, through the analysis of market trends, grasping the latest demand for electronic products, and predicting the future direction of development to determine the goal of mold development. At the same time, it is also necessary to understand the advantages and disadvantages of similar products through the analysis of competitive products to provide a reference for mold development.

Mold Design & Simulation Best Practices

The design stage is the core of mold development. Excellent design can not only directly affect the production efficiency of the mold, but also the quality of the final product. Designers need to use professional CAD software to conduct 3D modeling and simulation to ensure the feasibility and efficiency of the design. In addition, the design work should also include the planning of the manufacturing process, and the structural strength and thermal stability analysis of the formed product.

Material Selection Trade-Offs

The choice of material is crucial to the performance of the mold. Usually die steel needs to have good wear, toughness, and heat treatment properties. For consumer electronics mold, it may also be necessary to choose corrosion-resistant materials to adapt to use in complex environments. Depending on the specific requirements of different parts, engineers need to precisely select the right material and consider the cost-benefit ratio.

High-Precision Machining Technologies

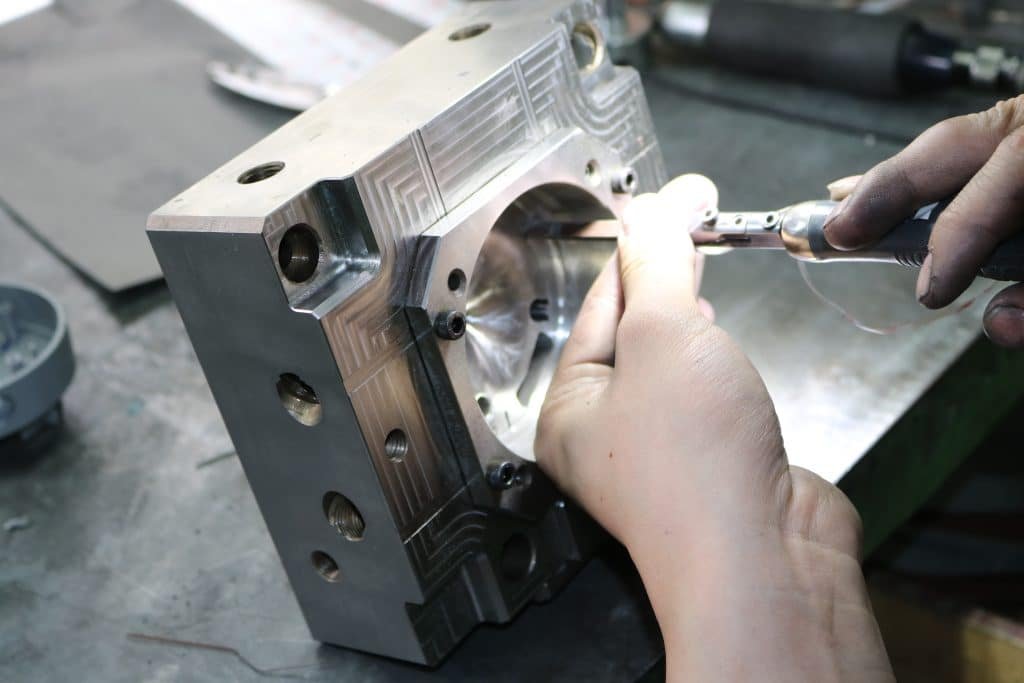

In the processing stage, the mold manufacturer will use a CNC machining center, electric discharge machine, wire cutting machine, and other high-precision equipment to ensure the accuracy of the mold. At the same time, to achieve efficient production, the processing process will optimize the mold components, reduce the processing difficulty, and shorten the production cycle.

Assembly Process & Quality Control

Assembly is the accurate assembly of each part of the mold into a complete system. This process requires a high degree of precision and experience, and any small deviation can lead to quality problems when the product is manufactured.

Testing is the final stage of the entire mold development, but it is also an important step in the acceptance of mold quality. At this stage, engineers will debug the mold and carry out strict production tests.

The consumer electronics mold components not only tests the design ability and production technology of enterprises but also tests the ability of enterprises to respond to market changes. Here are the detailed steps:

Market Research and Demand Analysis

Market research is the first step in the mold development process, which often requires a thorough investigation and analysis of the target market. The purpose is to clarify the object and direction of development and predict the future market competitiveness of the product. There are a wide variety of consumer electronics products on the market, from smartphones, and tablets to smart wearable devices, etc., which have extremely high requirements for the accuracy and reliability of meta accessories. At this stage, the information you need to understand includes the price, performance, user evaluation of competitive products, etc., but also pay attention to the technological development dynamics in the industry, to determine your product positioning and advantages.

The Importance of Design and Modeling Simulation

Excellent mold design can directly determine production efficiency and product quality. Designers need to accurately understand the function and structure of the product, and design a mold structure that can mass-produce high-precision electronic components. Modeling and simulation analysis using 3D design software can help designers anticipate possible problems and solve them. For example, for the lens holder mold of a mobile phone camera, the designer needs to ensure that the mold can accurately determine the position of each lens component, so as not to affect the image quality.

Trade-offs in Material Selection

The material of the mold needs to have good wear resistance and thermal stability to ensure the stability and service life of the mold under long-term high-pressure and high-temperature conditions. In addition, the selected materials must be easy to process, to reduce production costs. For specific electronic components, such as memory card sockets, charging interfaces, etc., the material also needs to have specific conductive properties or other physical properties. Therefore, in the choice of mold materials, there should be a comprehensive balance between economy, processability, and practicality.

High-precision Machining Technology

With the trend of consumer electronics products to be thinner and smaller, the precision requirements for mold processing are also getting higher and higher. Through high-precision machining processes, such as CNC machining, electric discharge, wire cutting, etc., you can ensure the size, shape, and position accuracy of the mold parts. Using simulation software to simulate the machining process can also optimize the machining path, reduce the production cost, and ensure product accuracy.

Assembly and Quality Control

The mold assembly process is a very critical step in mold production, which requires assembly workers to have rich experience and accurate operating skills. The position, direction, and fastening strength of each mold part in the assembly process need to be strictly controlled to ensure the accuracy of the mold assembly. At the same time, after the assembly is completed, the quality of the mold needs to be tested to ensure that the mold can run stably and produce qualified products.

Performance Testing and Optimization

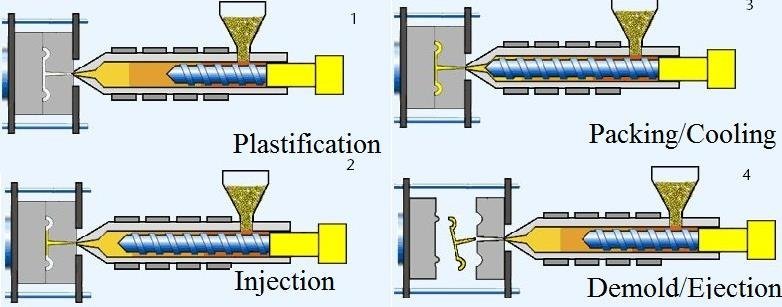

In the process of mold development, performance testing is an indispensable link. The mold is tested and run under real production conditions, and its potential problems can be found and improved in time. For example, in the production process, the temperature control of the mold will affect the flow and cooling speed of the plastic material of the part, which in turn affects the appearance and dimensional accuracy of the product. Through repeated testing and tuning of the mold, its stability and production efficiency can be improved, thereby reducing the overall cost.

Conclusion

All in all, the development of consumer electronics mold is a comprehensive engineering project, that involves market research, design, material selection, processing, assembly, and testing. A precise mold plays a vital role in the entire production process, which is directly related to the quality, cost, and delivery cycle of the finished product. Therefore, any enterprise involved in the consumer electronics industry must pay attention to the development and design of molds, which is not only the embodiment of technical strength but also the key factor for enterprises to win the market. Through continuous technological innovation and quality control, promote the development of consumer electronics mold to a higher standard, to help enterprises stand out in the complex market competition.