Thermoplastic Polyurethane (TPU) is a versatile polymer known for its elasticity, transparency, and resistance to oil, grease, and abrasion. Its unique properties make it a popular choice in various industries, from medical devices to consumer electronics. However, understanding the safety aspects of TPU is crucial for its effective and responsible application.

What Is TPU?

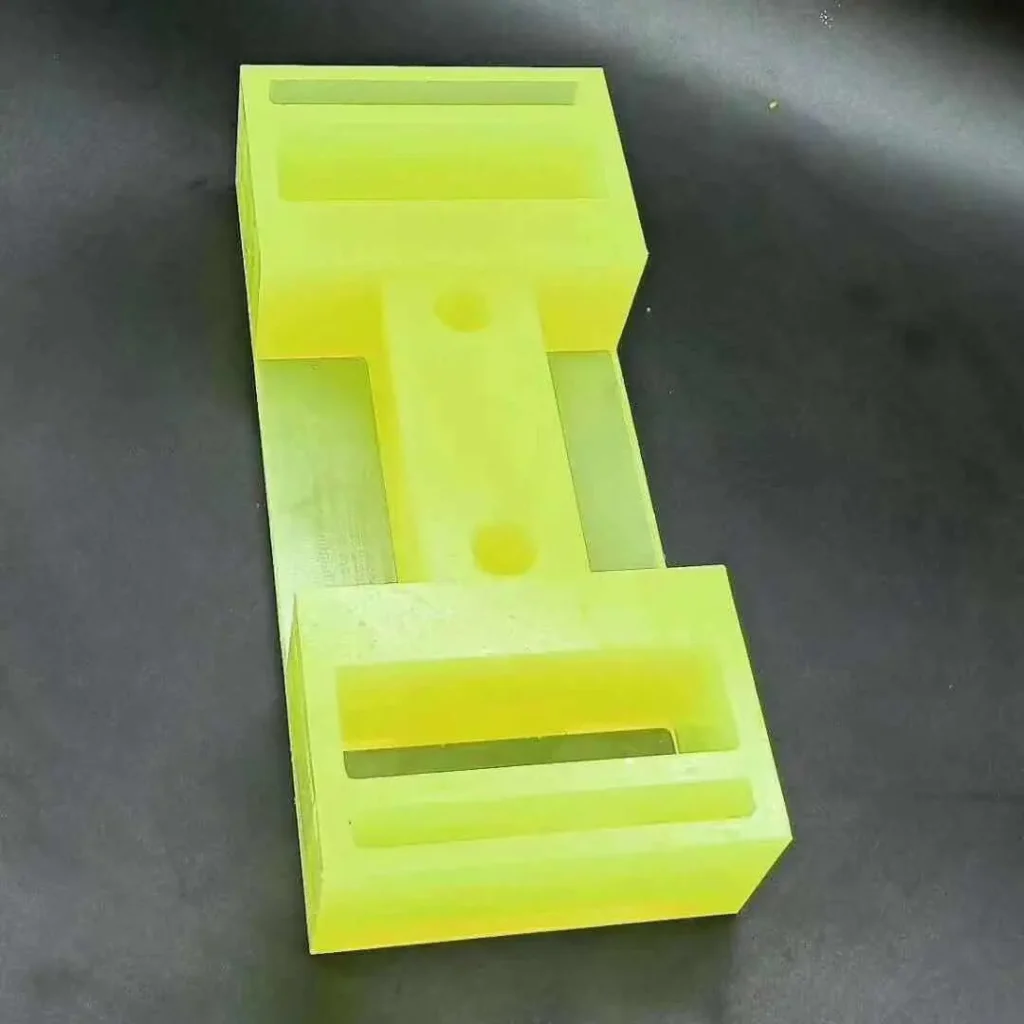

TPU is short for thermoplastic elastomer, a material that has the properties of both rubber and plastic. The polyaddition reaction of diisocyanates with diols leads to a flexible and durable material. TPU can be processed using conventional methods such as TPU injection molding and extrusion, rendering it versatile for various manufacturing requirements.

Key Properties:

- Hardness Range: 60A–80D (Shore scale)

- Temperature Resistance: -40°C to 120°C

- Elongation: 300–700%

The Composition of TPU

The primary components of TPU include:

- Diisocyanates: These are responsible for the rigidity of the polymer chain.

- Polyols (polyether or polyester-based): They provide flexibility and elasticity.

- Chain extenders: Short-chain diols that modify the hardness and mechanical properties of the TPU.

This provides versatility to TPU, which can be adapted by changing the ratios of these components to give a particular application hardness, elasticity, and other properties.

Material Safety:

- No BPA/Phthalates: Unlike PVC, TPU avoids endocrine-disrupting additives.

- REACH Compliant: Meets EU standards for chemical safety.

TPU Plastics Manufacturing Process

TPU is manufactured in several processing stages:

- Polyaddition Reaction: Diisocyanates react to polyols to produce prepolymers

- Chain Exyemsion: The prepolymers are reacted with chain extenders to obtain the desired molecular weight and properties.

- Compounding: The TPU produced is then cooled down and processed into pellets for easier handling and processing.

- Energy Use: 80–100 MJ/kg (lower than silicone’s 150 MJ/kg).

This enables fine-tuning of the material’s properties to produce the desired characteristics with high precision and replicability in the resulting product.

Is TPU Safe for Food?

TPU is indeed rated as safe for food contact applications. It does not contain harmful substances such as formaldehyde and plasticizers, which allows it to be used in food packaging and kitchen utensils. Because TPU does not emit harmful substances when processed this way, human health is protected from potential chemical hazards.

FDA Compliance:

- 21 CFR 177.1680: Approved for food-contact applications.

- Conditions: Avoid temperatures >100°C to prevent degradation.

Applications:

- Reusable food pouches, baby bottle nipples.

- Leaching Tests: <0.01 ppm heavy metals (FDA limit: 0.1 ppm).

Why TPU Could Be The Best Material In The Medical Industry

This also makes TPU a great choice for medical applications, where biocompatibility and elasticity are paramount. It finds wide utility with applications in medical devices like catheters, surgical instruments, and tubing. It can also endure sterilization techniques without degrading, so it does not compromise patients’ health, prolonging the life of treatment devices.

The Environmental Impact of TPU Plastics

TPU is recognized for its environmental friendliness:

- Recyclability: TPU materials are very recyclable, and the waste produced in this process can be recycled and reused, reducing the problem of environmental pollution.

- Degradability: TPU exhibits greater degradability than many traditional plastic materials under certain conditions, thus minimizing its long-term pollution of soil and water sources.

- Compliance with Environmental Regulations: Many TPU materials products comply with strict environmental regulations, such as the EU’s REACH regulations and RoHS directive, ensuring that their production and use have minimal environmental impact.

| Factor | TPU | PVC |

| Recyclability | Mechanically recyclable | Rarely recycled |

| Biodegradability | No (but recyclable) | No |

| Carbon Footprint | 3.2 kg CO2/kg | 5.8 kg CO2/kg |

Is TPU Safe for Human Health?

Extensive studies have shown that TPU is non-toxic and safe for human health. It does not contain harmful chemicals like phthalates, latex, or Bisphenol A (BPA), making it suitable for direct skin contact applications, such as wearable devices and medical equipment. Its hypoallergenic properties further enhance its suitability for sensitive applications.

- Skin Contact: Non-irritating (OECD 439 certified).

- Inhalation Risk: Minimal VOCs at <120°C processing.

- Toxicity: LD50 >2,000 mg/kg (classified as non-toxic).

Regulatory and Standardization of TPU for Its Secure Use

Several regulations and standards have been set to maintain TPU’s safe usage:

- ISO 10993: In China, medical-grade TPU products must conform to ISO 10993 production standards before being used.

- FDA(Food and Drug Administration) Compliance: TPU-based materials can only be used in food contact applications in the United States if they comply with FDA regulations, as such materials in contact with food must not pose a potential health risk.

By complying with these criteria, TPU materials products can be assured safe for the intended uses and pose no danger to consumers or patients.

TPE vs. TPU: Safety Comparison

Both Thermoplastic Elastomers (TPE) and Thermoplastic Polyurethanes (TPU) are considered safe materials, but they have distinct characteristics:

| Property | TPE | TPU |

| Hardness Range | 0A to 100A | 60A to 70D |

| Flexibility | Softer and more flexible | More rigid but offers better load-bearing capacity |

| Chemical Resistance | Less resistant to abrasion, grease, oils, chemicals, and extreme temperatures | More resistant to abrasion, grease, oils, chemicals, and extreme temperatures |

| Applications | Suitable for products requiring softness and flexibility (e.g., toys, grips) | Ideal for high-performance applications requiring durability (e.g., industrial components) |

Regarding safety, both materials are non-toxic and comply with environmental regulations. The choice between TPE and TPU depends on the application’s specific requirements.

Best Use For:

TPU: Medical devices, automotive seals.

TPE: Consumer goods, soft-grip handles.

Cost of TPU Materials in Injection Molding

The cost of TPU materials in injection molding depends on several factors, including material grade, processing requirements, and production volume. Here’s a breakdown of cost considerations:

| Factor | Impact on Cost |

| Raw Material Cost | Higher than standard plastics but varies by grade |

| Processing Complexity | Requires precise temperature and pressure control |

| Tooling Costs | Mold design affects cost efficiency |

| Production Volume | Larger volumes reduce per-unit costs |

While TPU is more expensive than some traditional plastics, its durability, flexibility, and safety make it a cost-effective choice in long-term applications.

- Material Cost: 3–8/lb(medical−grade:3–8/lb(medical−grade:10–15/lb)

- Mold Cost: 20,000–50,000 (complex geometries).

- Cycle Time: 30–60 seconds (faster than silicone).

Savings Tip: Use gas-assisted molding to reduce material use by 15%.

Common Applications of TPU

TPU has valuable properties that make it suitable for various industries:

| Industry | Use Case | Benefit |

| Automotive | CVJ boots, seals | Oil resistance, durability |

| Footwear | Shoe soles | Cushioning, abrasion resistance |

| Electronics | Phone cases | Shock absorption, clarity |

| Medical | Tubing, catheters | Biocompatibility, flexibility |

- Consumer Electronics: Phone case protector, smartwatch band, laptop cover.

- Footwear: High-performance shoes and insoles because of TPU’s cushioning and durability.

- Automotive: Gaskets, seals, and interior parts must be flexible and wear-resistant.

- Key Applications: Conveyor belts, seals, and impact-resistant parts.

- Medical Equipment: Catheters, tubing, wearable medical devices (TPU offers biocompatibility).

10 FAQs About TPU Injection Molding and Material Selection

1. What is TPU material, and what makes it unique for injection molding?

Thermoplastic Polyurethane (TPU) combines elasticity, abrasion resistance, and chemical stability. Its shore hardness range (60A–80D) and ability to bond with substrates (e.g., metals, plastics) make it ideal for overmolding grips, seals, and flexible components.

2. How does TPU compare to TPE or silicone for injection molding?

| Property | TPU | TPE | Silicone |

| Tensile Strength | 30–60 MPa | 10–30 MPa | 5–10 MPa |

| Abrasion Resistance | Excellent | Moderate | Low |

| Cost | $3–8/kg | $2–5/kg | $10–25/kg |

| TPU excels in high-stress applications (e.g., industrial belts), while silicone suits extreme temperatures. |

3. What industries benefit most from TPU injection molding?

- Automotive: Vibration-damping mounts, CVJ boots.

- Medical: Catheters, biocompatible tubing (ISO 10993 certified).

- Consumer Goods: Phone cases, sports equipment.

4. What are the optimal processing conditions for TPU injection molding?

- Melt Temperature: 180–220°C (varies by TPU grade).

- Mold Temperature: 20–60°C to prevent warping.

- Injection Pressure: 500–1,500 psi (low-pressure molding reduces internal stress).

5. How do I reduce defects like air traps or sink marks in TPU parts?

- Mold Design: Use venting channels (0.02–0.03mm) and adequate gate sizes.

- Process Control: Maintain consistent cooling rates (±2°C).

- Material Drying: Preheat TPU pellets at 80–100°C for 4 hours to avoid moisture bubbles.

6. Can TPU be overmolded onto other materials?

Yes. TPU adheres well to:

- Metals: Aluminum, stainless steel (via mechanical interlocks).

- Plastics: ABS, PC, nylon (chemical bonding after plasma treatment).

- Applications: Tool handles, medical device grips.

7. What certifications ensure TPU material safety for medical or food-contact applications?

- Medical: ISO 10993, USP Class VI.

- Food Contact: FDA 21 CFR 177.1680, EU 10/2011.

- General: REACH, RoHS compliance.

8. How does TPU recycling work, and is it cost-effective?

- Mechanical Recycling: Grind scrap TPU into pellets (loses 10–15% properties).

- Chemical Recycling: Depolymerize TPU into raw materials (higher cost).

- Cost: Recycled TPU costs 20–30% less than virgin material but requires quality testing.

9. What tooling considerations are critical for TPU molds?

- Mold Material: Hardened steel (e.g., H13) for high-wear areas.

- Surface Finish: SPI-C1 (textured) to hide flow lines.

- Ejection System: Stripper plates to avoid damaging soft TPU parts.

10. How do I evaluate a TPU injection molding supplier’s expertise?

- Portfolio: Request examples of TPU overmolding or medical-grade projects.

- Testing Capabilities: Verify they perform tensile tests, FTIR analysis, and fatigue testing.

- Compliance: Confirm ISO 13485 (medical) or IATF 16949 (automotive) certifications.

Conclusion

TPU (Thermoplastic Polyurethane): a versatile, flexible, durable, and safe material. It is a common material for food packaging, medical applications, consumer goods, and industrial components. It is recognized as safe for human health and in harmony with international safety laws, making it a great tool that works for many industries.

TPU vs. TPE: TPU will be stronger and more resistant to wear and tear; TPU is typically a safer and less toxic material than TPE, so think of them as very similar, with TPU being more for higher performance stuff. Also, despite TPU often being the more expensive option for injection molders, considering its long-term benefits, it is worth the price increase.

Manufacturers and product designers still turn to TPU, a safe, high-performance material.