How to Find Overmolding Services in China?

Introduction to Overmolding Services in China

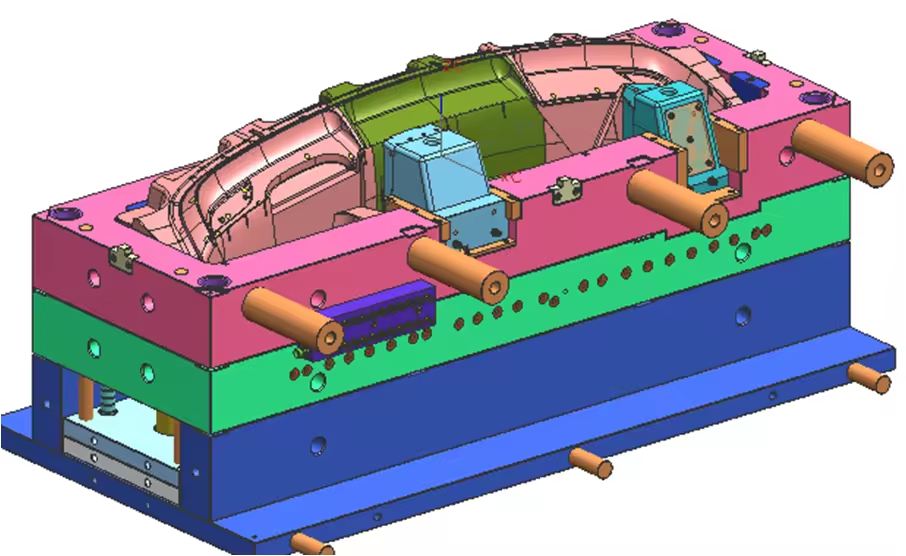

Overmolding is a highly advanced technique used in the manufacturing of plastic parts. In this process, two or more materials are molded together to create a single component. By bonding materials like plastic and rubber or plastic with metals, this process offers improved durability, functionality, and aesthetics. For manufacturers looking to optimize their production process, overmolding presents unique advantages such as enhanced product performance, reduced assembly costs, and increased design flexibility.

With its extensive industrial capabilities, China has become one of the leading global hubs for overmolding services. Whether you are an entrepreneur or a large corporation, sourcing overmolding services in China can be a cost-effective and strategic choice. This blog will guide you on how to find reliable overmolding services in China, what to consider when choosing a supplier, and the benefits of overmolding in the manufacturing process.

What is Overmolding?

Overmolding involves injecting a second layer of material over an already formed substrate or base material to create a part with a multi-material construction. This technique enhances the performance and aesthetics of a product by combining materials with different properties, such as soft-touch elastomers for grip or metal inserts for strength.

Overmolding can be performed in two primary forms:

- Two-shot overmolding: This involves injecting two different materials into the mold at separate stages, typically using two injection units.

- Insert overmolding: A pre-made component (often metal or plastic) is placed into the mold, and the second material is injected around it to form the final part.

Why Choose Overmolding for Your Manufacturing Needs?

Overmolding offers several benefits, making it an attractive choice for many industries:

- Enhanced Durability: By combining materials like rubber and plastic, overmolded products often have better resistance to wear and tear, making them ideal for high-use applications.

- Improved Aesthetics: The overmolding process allows for a variety of textures and colors, improving the overall look and feel of the product.

- Reduced Assembly Costs: Since the materials are molded together in one process, the need for secondary assembly steps is eliminated.

- Better Ergonomics: The technique allows manufacturers to incorporate soft-touch or grippy materials where needed, improving the comfort and usability of products.

- Customization: Overmolding provides design flexibility to create complex shapes and multi-material structures that would be difficult or impossible to achieve with traditional injection molding.

How to Find Overmolding Services in China?

Finding a reliable overmolding service provider in China can be a challenging task, especially if you are unfamiliar with the local market. However, with a structured approach, you can locate a trustworthy supplier that meets your business needs. Here are key steps to help you find overmolding services in China:

1. Conduct Online Research

The first step in finding overmolding services in China is to conduct thorough online research. Websites like Alibaba, Made-in-China, and Global Sources are popular platforms where manufacturers and suppliers list their services. You can search for “overmolding services” or “overmolding manufacturers in China” to find a range of suppliers. Pay attention to:

- Customer reviews and ratings

- Product photos and descriptions

- Years of experience in overmolding

- Certifications or industry memberships

2. Check for Certifications and Compliance

When outsourcing manufacturing to China, it’s crucial to ensure that the company follows industry standards and quality control measures. Look for certifications such as:

- ISO 9001 (for quality management)

- ISO 14001 (for environmental management)

- UL Certification (for safety standards in electronics)

These certifications will help ensure that the overmolding process meets international standards and regulatory requirements.

3. Evaluate the Supplier’s Capabilities

Not all manufacturers are equipped to handle the complexities of overmolding. It’s important to evaluate a supplier’s technical capabilities. Some critical questions to ask include:

- What types of materials do they specialize in for overmolding?

- Do they offer custom design services, or do they only work with standard molds?

- What type of injection molding equipment do they use?

- Can they handle both small-scale and mass production runs?

A company that can demonstrate a deep understanding of the overmolding process and material compatibility will be better suited to meet your specific requirements.

4. Request Samples

Before committing to a large-scale order, request samples of overmolded parts to assess the supplier’s capabilities and product quality. The samples will help you evaluate:

- Material bonding: Ensure the materials are well-bonded and the overmolding process is smooth.

- Finish quality: Check for any visible defects, such as bubbles, cracks, or uneven surfaces.

- Tolerances: Ensure that the molded parts meet your precise dimensional requirements.

5. Discuss Production Lead Times and Costs

Discuss production timelines and cost structures upfront to avoid unexpected delays or expenses. Keep in mind that the cost of overmolding may vary depending on:

- Material costs

- Complexity of the design

- Mold creation and setup

- Quantity of parts

Ensure that the supplier can provide you with a clear and detailed quote and realistic lead times for your order.

6. Visit the Factory (If Possible)

If you are ordering a large or complex production run, consider visiting the factory in China to evaluate the manufacturing facility in person. A visit allows you to inspect:

- Production capabilities: Check the equipment and technologies used in the overmolding process.

- Quality control practices: Ensure the company has robust quality checks in place.

- Working conditions: Verify that the supplier adheres to ethical labor practices.

Why Choose China for Overmolding Services?

China has emerged as a leading global hub for overmolding services due to its low labor costs, advanced manufacturing technologies, and well-established supply chain network. Working with overmolding suppliers in China can provide several advantages:

- Cost savings: China’s manufacturing industry benefits from economies of scale, which can significantly lower production costs.

- Access to advanced technologies: Many Chinese manufacturers use cutting-edge machinery and equipment for precise overmolding and injection molding processes.

- Skilled workforce: China has a large pool of skilled engineers and technicians who are well-versed in modern molding techniques.

- Flexibility in production volumes: Whether you need small batches for prototyping or large-scale mass production, Chinese suppliers can accommodate a variety of order sizes.

So why Choose BFY Mold for Your Overmolding Needs?

If you are looking for reliable and cost-effective overmolding services, BFY Mold is your trusted partner. Based in China, we specialize in high-quality injection molding and mold manufacturing, offering a wide range of services including:

- Mass production and on-demand production to meet your business needs

- CNC machining and mirror spark services for precise and high-quality mold finishes

- Custom overmolding solutions tailored to your design specifications

- Expert team with extensive experience in overmolding and multi-material product design

We have our state-of-the-art factory, ensuring that all our products meet the highest standards of quality and efficiency. Choose BFY Mold for your overmolding and injection molding needs, and experience world-class service at competitive prices.