Introduction

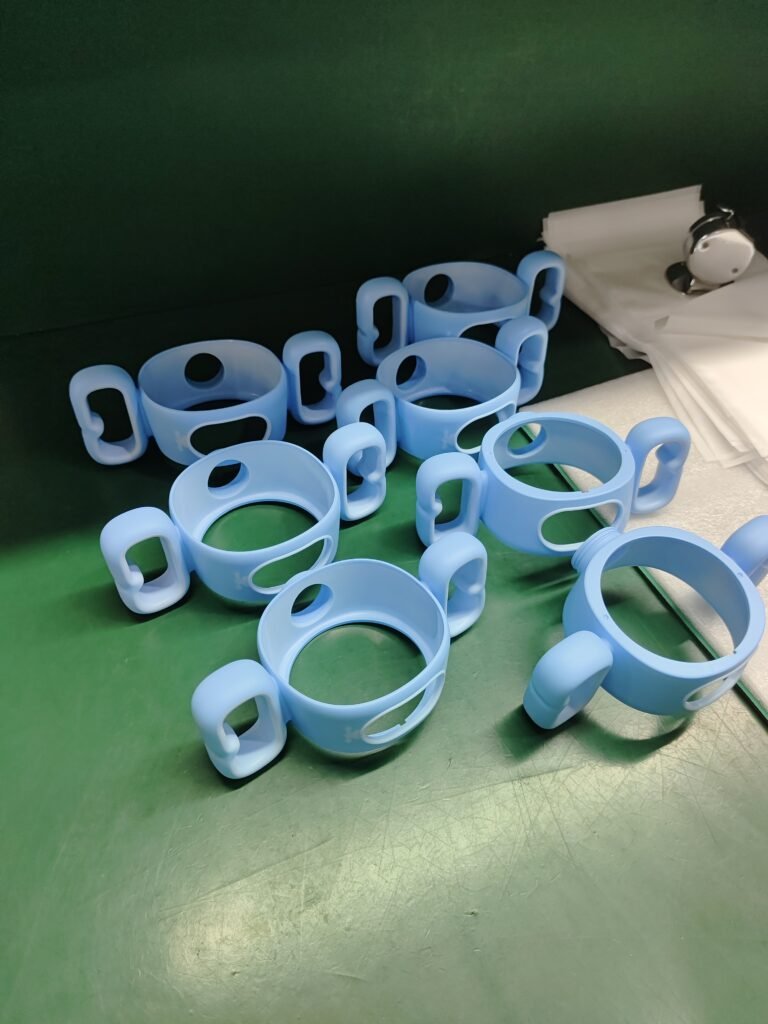

Quality control is paramount in the injection molding industry. Quality is one of the most important aspects of injection molding products, as customers expect high functional precision.

But to produce consistently high quality, you need solid planning, solid processes, and the right technology. This article discusses how to control the quality of injection molding products, complemented by useful tools and practices to achieve the best results.

Understanding the Importance of Quality in Injection Molding

1. Meeting Industry Standards

Injection molding products are used in many industries, such as automotive, medical, electronics, consumer goods, etc. Various industries have quality standards that manufacturers must comply with including ISO certificates and regulations.

2. Enhancing Customer Satisfaction

High-quality products lead to satisfied customers, repeat business, and a strong reputation in the market. Poor-quality items can result in complaints, returns, and a tarnished brand image.

3. Reducing Waste and Costs

By controlling the quality, you can avoid these defects and rejects which also contribute to material wastage and production costs.

Key Factors Affecting Control of the Quality of Injection Molding

1. Material Selection

Choosing the right plastic materials is crucial for producing durable and functional products. Consider factors like strength, flexibility, heat resistance, and compatibility with the injection molding process.

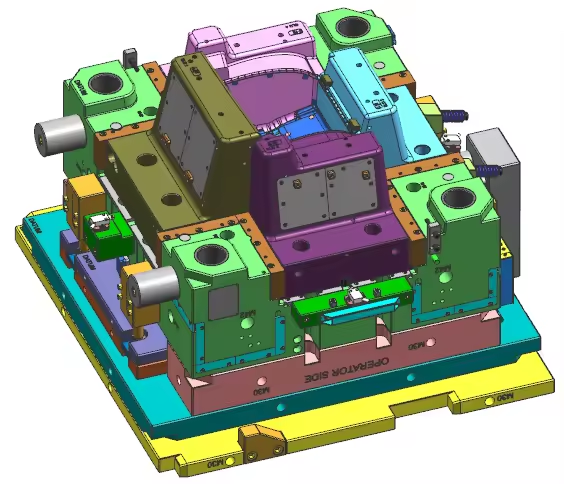

2. Mold Design

The design of the mold significantly impacts product quality. Poorly designed molds can lead to defects such as warping, sink marks, or flash.

3. Process Parameters

Critical parameters like temperature, pressure, and cooling time must be precisely controlled to ensure consistent quality.

4. Machine Maintenance

Regular maintenance of injection molding machines prevents malfunctions and ensures consistent production quality.

How to Control the Quality of Injection Molding Products?

1. Establishing Quality Control Systems

Quality control systems are responsible for monitoring and measuring production to ensure the standards are being met. Key components include:

- In-Process Inspection: Monitoring of production parameters.

- Quality Control: This must be physically checked for defects and inconsistencies.

- Statistical Process Control (SPC): For trends and variations data analysis.

2. Mold Design Accuracy Guaranteed

Advanced design software and simulation tools help detect and avoid potential problems before production. Molds are made to exact specifications through precision CNC machining.

3. Using High-Quality Materials

Work with reputable suppliers to source high-grade raw materials. Verify the material’s properties through testing to ensure suitability for the intended application.

4. Training the Workforce

Skilled operators are essential for maintaining quality. Regular training ensures the team understands the latest techniques, machinery, and quality standards.

5. Conducting Regular Machine Maintenance

Scheduled maintenance prevents breakdowns and ensures machines operate at peak efficiency. Calibration checks are vital for maintaining accuracy.

6. Monitoring Environmental Conditions

Factors like humidity and temperature can affect the molding process. Maintain a controlled environment to ensure consistent results.

Tools and Techniques for Quality Control

1. Advanced Inspection Tools

- Coordinate Measuring Machines (CMM): For precise dimensional analysis.

- Optical Microscopes: For identifying surface defects.

- Non-Destructive Testing (NDT): To evaluate structural integrity without damaging the product.

2. Process Automation

Automating the production process reduces human error and ensures consistency. Technologies like robotics and IoT-enabled machines provide real-time monitoring and data collection.

3. Defect Detection Systems

Use advanced imaging and AI-powered systems to detect defects early in the process, minimizing waste.

Common Defects in Injection Molding and How to Prevent Them

1. Warping

Cause: Uneven cooling.

Solution: Optimize cooling channels and ensure uniform temperature distribution.

2. Sink Marks

Cause: Insufficient packing pressure or cooling time.

Solution: Increase packing pressure and adjust cooling parameters.

3. Flash

Cause: Excess material escaping the mold cavity.

Solution: Ensure proper mold alignment and tighten clamping pressure.

4. Bubbles or Voids

Cause: Trapped air or moisture.

Solution: Dry the material thoroughly and adjust the injection speed.

Importance of Quality Certifications in Injection Molding

Obtaining certifications like ISO 9001 or ISO 13485 demonstrates a commitment to quality and compliance with international standards. These certifications are often required for industries like medical and automotive, enhancing trust and credibility.

Why Choose BFY Mold for High-Quality Injection Molding Products?

At BFY Mold, we prioritize quality in every aspect of our operations. With our state-of-the-art factory and advanced technology, we ensure each product meets the highest standards of precision and durability.

Our Services Include:

- Injection Molding and Mold Manufacturing: Precision engineering for reliable molds.

- Mass Production: Efficient and scalable manufacturing solutions.

- On-Demand Production: Flexible production tailored to your needs.

- CNC Machining: High-precision machining for intricate designs.

- Mirror Spark Technology: Enhanced product aesthetics and finish.

Why Partner with BFY Mold?

- Expertise: Decades of experience in mold making and injection molding.

- Advanced Technology: State-of-the-art equipment for superior results.

- Commitment to Quality: Stringent quality control processes at every stage.

Conclusion

Control of the quality of injection molding requires a combination of skilled personnel, advanced technology, and robust processes. By implementing best practices and collaborating with experienced manufacturers like BFY Mold, businesses can achieve consistent quality, reduce costs, and enhance customer satisfaction.