China is a global leader in mold manufacturing and service, including injection molding and CNC machining. There’s a part of the set that comes out of the Netherlands, which is the most recognizable — but most of the country’s mold manufacturers are known for their attention to detail and innovation fitted for every industry, including automotive and consumer electronics, as well as medical devices.

This article features six of the best mold manufacturers in China, with a special mention of BFY Mold for its one-stop services and well-equipped facilities.

1. BFY Mold: Precision and Innovation in Mold Manufacturing

BFY Mold is a premier mold manufacturer specializing in injection molding, mold making, mass production, on-demand production, CNC machining, and mirror spark technology. With its factory equipped with advanced machinery, BFY Mold ensures high-quality and efficient production processes.

Key Services:

- Injection Molding and Mold Making: BFY Mold offers end-to-end solutions from mold design to production, ensuring precision and quality at every stage.

- CNC Machining: Utilizing advanced CNC machines, the company provides high-precision components tailored to client specifications.

- Mirror Spark Technology: This cutting-edge technology enhances the surface finish of molds, resulting in superior product aesthetics.

- Mass and On-Demand Production: Whether for large-scale manufacturing or small-batch production, BFY Mold adapts to client needs with flexibility and efficiency.

BFY Mold’s commitment to quality and innovation positions it as a trusted partner for businesses seeking reliable mold manufacturing solutions.

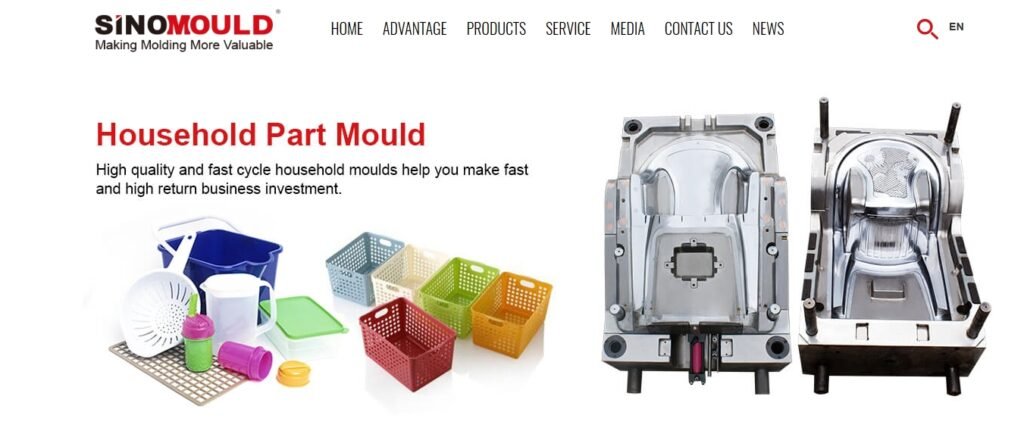

2. SinoMould: A Pioneer in Plastic Mould Manufacturing

Established in 1999, SinoMould is a renowned plastic mold manufacturer in China, specializing in plastic mold design, machining, and injection molding. The company has produced over 300,000 sets of plastic molds, serving industries such as automotive, home appliances, and medical devices.

Key Services:

- Plastic Mold Design and Machining: SinoMould emphasizes precision in mold design and machining, ensuring high-quality production.

- Injection Molding Services: Offering one-stop plastic injection molding solutions, the company caters to diverse client needs.

- Research and Development: Continuous innovation and pursuit of excellence are at the core of SinoMould’s operations.

With a strong focus on quality and customer satisfaction, SinoMould remains a leader in the plastic mold manufacturing industry.

3. Richfields Corporation: Excellence in Injection Molding

Richfields Corporation is a premier mold manufacturer in China, known for producing top-quality, durable products and exceptional service. The company specializes in plastic injection molding, serving various industries with a commitment to quality and innovation.

Key Services:

- Custom Injection Mold Solutions: Richfields offers tailored solutions to meet specific client requirements.

- Advanced Manufacturing Facilities: Equipped with state-of-the-art machinery, the company ensures precision and efficiency in production.

- Comprehensive Customer Support: Richfields emphasizes superior customer service, ensuring client satisfaction throughout the production process.

Partnering with Richfields guarantees access to high-quality injection molding solutions and a reliable manufacturing process.

4. Topworks Plastic Mold: Quality and Efficiency in Mold Making

Topworks Plastic Mold is a China-based plastic mold and injection molding company offering one-stop services with competitive pricing and quick delivery. The company specializes in custom plastic injection molding, catering to various industries with a focus on quality and efficiency.

Key Services:

- Custom Plastic Injection Molding: Topworks provides tailored solutions to meet diverse client needs.

- Rapid Prototyping and Production: The company focuses on quick turnaround times and ensures timely product delivery.

- Comprehensive Mold Design and Manufacturing: Topworks offers end-to-end services from design to production, ensuring high-quality outcomes.

With a commitment to customer satisfaction and quality, Topworks stands out as a reliable partner in the mold manufacturing industry.

5. UPMold: Expertise in Plastic Injection Mold Making

UPMold is a top-level quality plastic injection mold maker in China, specializing in mold making, molding, and assembling finished units. The company serves various industries, providing high-quality and durable mold solutions.

Key Services:

- Plastic Injection Mold Making: UPMold offers precision mold making services tailored to client specifications.

- Molding and Assembly: The company provides comprehensive services, including molding and assembling finished units.

- Custom Solutions: UPMold specializes in creating custom molds to meet specific client requirements.

With a focus on quality and customer satisfaction, UPMold is a trusted name in the plastic injection mold manufacturing industry.

6. Sincere Tech: Comprehensive Plastic Injection Molding Services

Sincere Tech is recognized as one of the top plastic injection molding companies in China, offering custom injection mold solutions. The company provides a wide range of services, including mold design, manufacturing, and injection molding, catering to various industries.

Key Services:

- Custom Injection Mold Solutions: Sincere Tech offers tailored solutions to meet diverse client needs.

- Advanced Manufacturing Capabilities: Equipped with state-of-the-art machinery, the company ensures precision and efficiency in production.

- Commitment to Quality: Sincere Tech emphasizes quality in all aspects of its operations, ensuring high-quality outcomes for clients.

With a dedication to innovation and customer satisfaction, Sincere Tech remains a leading player in the plastic injection molding industry.

Top 10 FAQs When Choosing Mold Manufacturers in China

1. What certifications should I look for in Chinese mold manufacturers?

Ensure they hold ISO 9001 (quality management), ISO 14001 (environmental standards), and IATF 16949 (automotive compliance). For medical molds, verify ISO 13485 and FDA compliance.

2. How do I verify the experience and expertise of a Chinese mold supplier?

- Request case studies or client references in your industry (e.g., automotive, medical).

- Check their portfolio for projects involving similar materials (e.g., P20 steel, aluminum) and complexities (multi-cavity molds, micro-features).

3. What materials do Chinese mold manufacturers typically use for molds?

- Steel molds: Common grades include 718, NAK80, and S136 for high-volume production.

- Aluminum molds: Often 7075-T6 for prototypes or low-volume runs.

- Specialized options: Beryllium copper for high-heat applications.

4. What is the average cost of a custom mold from China?

Costs range from 5,000–5,000–80,000+, depending on:

- Material: Steel molds cost 2–3x more than aluminum.

- Complexity: Side actions, lifters, or micro-features add 15–40% to the price.

- Size: Larger molds (e.g., automotive bumpers) require more material and machining time.

5. How long does it take to manufacture and ship a mold from China?

- Production time: 6–12 weeks for steel molds; 3–6 weeks for aluminum.

- Shipping: 1–3 weeks by sea (cost-effective) or 3–5 days by air (premium cost).

6. How do Chinese mold manufacturers handle language barriers and communication?

Reputable suppliers:

- Employ English-speaking engineers and project managers.

- Use collaborative tools (e.g., Zoom, WeChat) for real-time updates.

- Provide detailed documentation (CAD files, inspection reports) in English.

7. What safeguards protect intellectual property (IP) when working with Chinese mold makers?

- Sign NDAs (Non-Disclosure Agreements) enforceable in Chinese courts.

- Work with manufacturers that have ISO 27001 (information security) certification.

- Avoid sharing full CAD files until contracts are finalized.

8. Can Chinese mold manufacturers handle both prototyping and mass production?

Yes. Many offer end-to-end services:

- Prototyping: 3D-printed or aluminum molds (50–1,000 units).

- Mass production: Multi-cavity steel molds (10,000+ units/month).

- Bridge tooling: Hybrid molds for mid-volume runs (1,000–5,000 units).

9. What quality control processes do Chinese mold factories follow?

- Mold flow analysis to predict defects (warping, sink marks).

- CMM inspections to ensure tolerances within ±0.005mm.

- T1 sample testing with detailed inspection reports before mass production.

10. How do I handle mold maintenance and repairs with an overseas supplier?

Leading manufacturers provide:

- Remote troubleshooting: Video calls to diagnose issues.

- On-site support: Partner with local service centers in your region.

- Spare parts kits: Pre-ship replacement components (e.g., ejector pins, heaters).

Conclusion

China’s mold manufacturing industry is characterized by its diversity, innovation, and commitment to quality. The six companies highlighted above, including BFY Mold, exemplify these qualities, offering a wide range of services tailored to meet the specific needs of various industries.