Hot runner systems in mold design are essential for efficient and cost-effective injection molding, improving product quality, and minimizing material waste. By carefully selecting and using the right hot runner in mold applications, manufacturers can achieve consistent results, reduced cycle times, and lower costs.

This guide delves into the key factors for choosing hot runner systems, from design considerations to material compatibility, ensuring your mold setup meets production demands.

Selection and use of hot runner

The hot runner system is a relatively complex technology in the field of injection molding. When mold designers and mold users choose and purchase hot runner systems, there are many issues to consider and pay attention to. Industry experts have given us a list of tips, which BFY Mold shares with you:

Choice of Hot Runner Supplier

When the mold manufacturing company designs and makes a hot runner mold, it is not simply to buy a hot runner system from the supplier and install it on the mold. But from the conceptual design stage of the hot runner mold to the actual production process of the mold, to the use of the final mold, there are many meticulous and close coordination and cooperation in technology and trade between the mold manufacturing company and the hot runner supplier.

How to choose a hot runner supplier?

When choosing a hot runner supplier, it is necessary to focus on two basic aspects:

1. Number and quality of hot runner components

There are three types of hot runner systems: hot tip, SPRUEGATING, and VALVE GATING. Each type can be subdivided into many product families. NOZZLE, for example, nozzle section diameter can range from 4 mm to 12 mm. Nozzle is also shaped into a range of different sizes. Nozzle gate inserts are also available in many variants to meet different application requirements, so the richer the product range of hot runner suppliers, the better.

In this way, the user can have a greater selectivity of hot runner components, and the type, size, weight, and application range of plastic parts produced with hot runner are wider, which is more conducive to optimizing the injection molding production process and product quality.

When plastic products are processed by injection molding, the hot runner system and hot runner mold work under high temperatures and high-pressure loads. Many factors lead to the failure of hot runner system components, and injection molding is mainly used in the production of large quantities of plastic parts. If there is any shutdown, the economic loss is very serious.

Therefore, the quality and reliability of the hot runner system are very important. Customers should have a deep understanding of the quality and application history of hot runner components produced by hot runner suppliers. Some of the more excellent hot runner manufacturers have been certified by international organizations with ISO quality standards.

2. Technical support and after-sales service

When using the hot runner mold, in addition to first choosing a reliable hot runner system, users should also consider whether they can get timely and effective technical support and after-sales service in case of hot runner problems.

Many suppliers have a strong technical support and service network in the countries and regions where their company is headquartered, and are equipped with full-time service staff who can visit customers at any time for troubleshooting. However, these manufacturers in other countries and regions apart from their company headquarters, often only set up some focus on product sales offices, technical support is relatively inferior, and users should pay attention to this factor.

How to choose a hot runner with technical details?

Users in the selection and purchase of the hot runner system will involve a lot of specific technical links. If the user has good hot runner-related technical knowledge, you can easily choose and buy, ensure that the injection molding production process is smooth, and improve product quality.

1. Correct selection of Hot Runner product series

Hot runner suppliers often make their hot runner components into product series according to the size and weight of processed plastic parts. For example, large plastic parts are processed with large-size nozzles, and small plastic parts are processed with small-size nozzles. Therefore, after the user correctly chooses the hot runner type (both the hot tip type and the valve type system), it is the choice of the hot runner product series; And thus determines the mold structure size and design and manufacture.

If the selection of the hot runner product series is not correct, it is found in the later stage of mold processing or the production of plastic parts, and the error is very serious and difficult to save. To help with the correct selection of the Hot Runner product series, each Hot Runner supplier has several guiding technical documents for reference. The user should work closely with the hot runner supplier to choose a good hot runner product series.

2. Injection pressure loss in the hot runner system

The injection pressure loss in the hot runner system cannot be ignored. Many hot runner mold users have a misunderstanding that the injection pressure loss of hot runner is much smaller than that of cold runner. The reason is that the plastic solution in the hot runner is always hot during the entire injection process.

Many times the situation is just the opposite: in the hot runner mold, due to the needs of the mold structure design, the activity interval of the solution in the hot runner system will be greatly increased. Therefore, the injection pressure loss in the hot runner system is often large. In practical applications, there are many difficulties in injection molding due to excessive pressure loss in the hot runner system. Therefore, for plastics with poor processing activity (such as PC, POM, etc.), the activity interval of the solution in the hot runner system is large, or the weight of the parts is large, etc., CAE software should be used for flow path analysis and calculation.

3. Selection of standard and non-standard hot runner systems

Each hot runner manufacturers provide both standard and non-standard hot runner systems. If possible, users should try to choose a standard hot runner system.

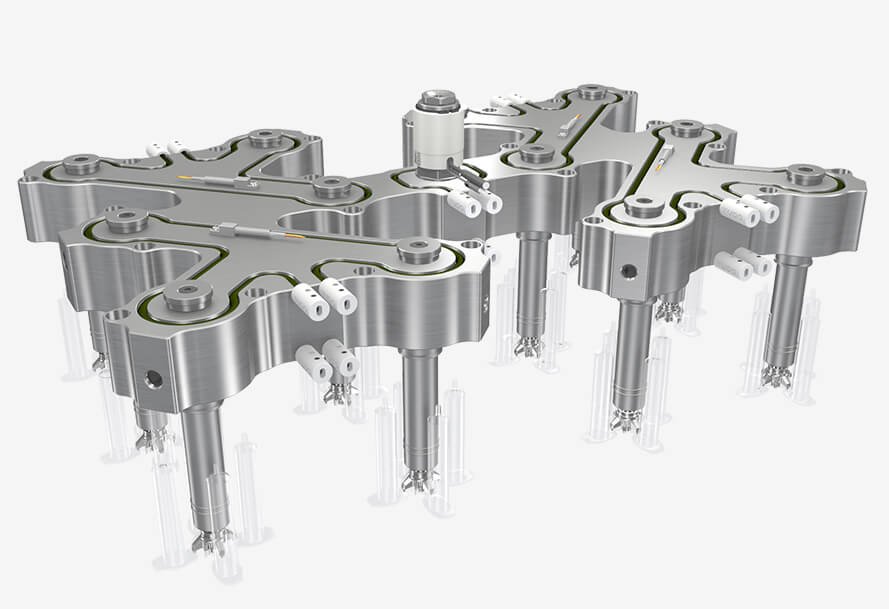

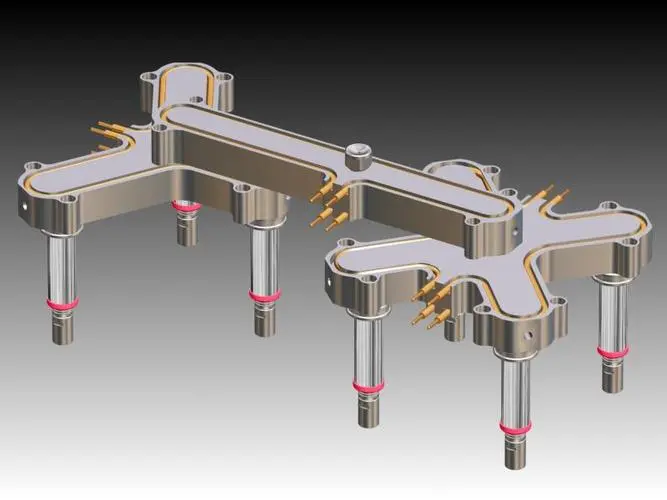

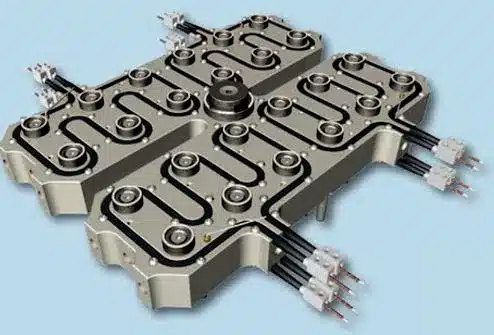

The advantage is that the standard hot runner system is lower than the non-standard hot runner system, and the delivery time is much shorter. The parts have interchangeability, which is conducive to future use and maintenance. Once a part is broken, buy another standard part and put it on. The shape of the common standard hot runner plate has a 2-cavity column, a 4-cavity column, an 8-cavity column, a 4-cavity X shape, and an 8-cavity XX shape.

4. Selection of cavity number and layout on the mold

When the user chooses the number of cavities in the design of the hot runner mold, in addition to increasing the production efficiency by putting as many cavities as possible, the design of the hot runner should also be considered. The choice of cavity number and layout on the mold should be conducive to the balance of plastic solution activity in the hot runner system.

For example, if several cavities of the same shape are arranged in a column, it is recommended that the number of cavities be 2 or 4, rather than 3. Because of the mold in a row of 2 or 4 cavities, its hot runner can be designed into a completely natural balance system. On the contrary, the 3-cavity mold needs to balance the human activity of the hot runner shunt plate.

The balance of activity depends on the quality of the work of the specific hot runner design staff, so the user should try to choose the number of cavities conducive to the balance of activity (such as choosing 16 cavities instead of 15 cavities, etc.) to eliminate any mistakes caused by the balance of human design activities.

5. Limitation of minimum cavity spacing

When designing molds for the production of small parts, people generally want to arrange the cavity spacing as close as possible, so that the mold can be compact and possibly put more cavities. However, the minimum cavity spacing is limited by the size of the minimum spacing between hot runner elements such as nozzles. Therefore, when designing a mold with a very close cavity interval, users should pay attention to checking the minimum nozzle interval to avoid rework in the mold design.

6. Types of processed plastics

The type of processed plastic is a very important consideration. If glass-reinforced plastics (such as glass-reinforced nylon materials, etc.) are processed, gate inserts with good wear resistance should be selected. If the processing of easy thermal decomposition of plastics (such as PVC) should be selected runner smooth, no active dead Angle of the hot runner system. If the processing of plastics with poor activity (such as PC) should consider the selection of a larger nozzle series and the use of a larger runner section size in the hot runner plate.

7. Maturity of hot runner products

A new hot runner product needs a long time to gradually improve. Hot runner manufacturers continue to introduce new products at the same time, which will also eliminate the practice proved unsuitable hot runner products. Therefore, users should try to choose good mature, relatively popular, hot runner products with a long history of application. For this kind of product, whether it is a hot runner manufacturer or other hot runner users, there are more experienced and successful cases for new users with little experience.

8. Status of the hot runner system before delivery

Some suppliers will perform certain tests on their hot runner systems before shipping them to users. For very important applications, actual injection molding experiments are even carried out. However, the test range of each hot runner supplier is not the same before the hot runner system is shipped. Users should be understood, so that they know what is in mind.

9. Selection of multi-zone temperature control for hot runner

If the user needs to purchase a large size and complex hot runner system, or process plastics that are sensitive to temperature and have a narrow processing parameter range, the hot runner design scheme with multiple areas of temperature control should be selected. This allows users to locally adjust and control the temperature distribution as needed.

An ideal hot runner system should have a uniform and consistent temperature distribution, but there will be many reasons for the temperature of the hot runner, such as the quality of the hot runner heating element, the excessive loss of heat at the combination of the hot runner system and the mold, and the different shear heat of the plastic solution in the hot runner. The larger the size of the hot runner system, the more complicated it is to choose the hot runner system with multi-zone temperature control.

10. What should I do if I have a color change request?

Some users use the same mold to produce the same variety of plastic parts with different colors, which is the application project with color change requirements.

When ordering a hot runner, try to choose a hot runner system with a small runner volume to speed up the color-changing process and reduce waste. At the same time, any runner turning point in the hot runner system must be rounded and smooth, without active dead corners. If the valve hot runner system is used to produce plastic parts with color change requirements, there is often a DEAD SPOT behind the valve needle, which must be paid special attention to!

11. A mold multi-cavity mold

The balance of activity must be considered when designing a mold with different shapes and cavities.

If the difference in size and weight of the parts is too large, and the difference in injection pressure of each cavity is more than 200-300 bar, it is difficult to achieve active balance by changing the size of the runner in the hot runner system. If the activity is unbalanced in a mold special-shaped multi-cavity mold, some parts will not be enough to maintain the pressure, and other parts will be overfilled, with large flash, and high residual stress. At this time, the valve hot runner system should be considered, or the overall design scheme of the mold should be changed. The valve system can close the early cavity gate at the right time to avoid the problem of excessive filling of these cavities.

12. Proportional relationship between the cavity and hot runner volume

Compared with the cavity volume, the runner volume of the hot runner system should not be too large. Otherwise, the plastic solution stays in the hot runner system for too long, which will produce thermal decomposition. Unable to produce qualified plastic parts.

If the weight of the plastic parts is too small, the scheme of cold and hot runners should be used. Because the injection volume increases after the use of a cold runner, it helps to improve the proportional relationship between the cavity and the volume of hot runner and shorten the residence time of plastic solution in the hot runner system.

13. Use trial molds

Hot runner molds are more precious, especially hot runner molds with high cavity numbers (such as 96,128 cavities, etc.), and the price is higher.

If you want to open up a new application field, lack experience, or try to use newer hot runner elements (such as nozzles or new gates), you should consider making a simple, single-cavity trial mold to carry out feasibility studies to verify the program. After gaining enough experience, we can make formal working molds with precious prices.

14. Drawing of hot runner elements on the mold drawing

Hot runner suppliers generally make their hot runner components into electronic galleries for users to use. When designing and drawing mold drawings, mold design staff can select the required nozzle and other component drawings from the electronic library of hot runner components and place them in the appropriate mold position. Because hot runner suppliers will often update their hot runner products, users should pay attention to the hot runner manufacturers constantly requesting the latest gallery.

Although people have begun to use 3D methods to design molds, at present, most of the hot runner suppliers of hot runner components’ electronic galleries are still 2D. Some manufacturers have begun to establish a 3D hot runner components library to meet the needs of the development of 3D mold design.

15. Warranty period

Hot runner suppliers will provide some warranty period for their hot runner products. The warranty period ranges from one to five years, depending on the hot runner manufacturer and the specific hot runner product item purchased by the user. During the warranty period, if the hot runner product occurs under the user’s normal operation and use, the hot runner supplier will give a free replacement.

The longer the warranty period, the better for the user. To guarantee the validity of the quality warranty, the user should respect the hot runner.