In modern manufacturing, metal stamping and plastic molding are important production processes these key components efficiently and effectively are crucial to ensure product quality and production efficiency. Effective plastic mold maintenance is critical to ensuring consistent production quality and minimizing costly downtime in manufacturing.

From automotive components to consumer electronics, molds endure wear, temperature fluctuations, and mechanical stress, making proactive care essential. The following mainly introduces various methods and techniques for maintaining metal stamping parts and plastic molds to help industrial practitioners improve production efficiency and extend the service life of equipment.

Pre-Assembly Inspection for Mold Longevity

1. According to the size of the punching shear force of the mold, the press with enough tonnage is correctly used. (The cargo of the general machine tool must be greater than the punching shear force of the mold)

2. Before the die is put on the machine, the gap of the blade edge of the die must be checked and adjusted to prevent the blade gap from being out of shape during the loading and unloading of the die during transportation. The adjustment can be made before the machine.

3. Before setting up the mold, clean the upper and lower surfaces of the mold to ensure that the mold mounting surface and the working table of the punching machine are crushed and the parallelism of the upper and lower mounting surface of the mold in the production.

4. The working table of the punching machine and the bottom surface of the slider must be parallel, and the deviation of the parallelism should be less than 0.03.

5. After the mold is ready, open the mold and clean all parts of the mold. Especially the guiding mechanism. For the surface parts (appearance parts) of the mold, the mold surface is clean and clean to ensure the quality of the parts. Lubricate each sliding part of the mold and inspect each part of the mold. Especially safety parts (such as punching waste holes, etc.).

6. After the sample is washed out, it must be immediately confirmed whether it conforms with the product specifications.

Real-Time Monitoring During Production Cycles

1. When the mold is used, the guide column and guide sleeve should be regularly lubricated.

2. Lubricating oil or stamping oil should be added to the corresponding parts and cutting edges of the mold regularly during production.

3. Double punching and cutting is strictly prohibited. Other items except stamping materials and lubricating oil should be kept away from the working area.

4. The iron powder in the cutting edge can not lag too much, should be handled in time, and regularly clean the waste, after the end of production to the mold for a comprehensive inspection, and a comprehensive cleaning of sassafras, to ensure the cleanliness of the mold.

Post-Use Cleaning & Preservation Protocols

1. The cutting edge of the mold must be ground after long-term use, and the cutting edge surface must be demagnetized after grinding, and it cannot be magnetic. Otherwise, it is easy to block material.

2. Spring and other elastic parts in the use of the spring are the most vulnerable to damage, usually fracture and deformation phenomena. The way to do this is to replace, in the replacement process must pay attention to the specifications and models of the spring, the specifications and models of the spring through the color, outer diameter, and length three to confirm, only in the case of the same three can be replaced.

3. The punch is easy to break, bend, and chew during the use of the mold, and the punch sleeve is generally chewed. Punch and punch sleeve damage are generally replaced with the same specification parts. The punch parameters mainly include the size of the working part, the size of the installation part, the length size, etc.

4. Tighten the parts and check whether the fastening parts are loose and damaged and the way is to replace the parts with the same specifications.

5. Press parts such as press plate, good force glue, etc., and discharge parts such as stripper plate, pneumatic jacking, etc. During maintenance, check the relationship between the parts of each part and whether there is damage. Repair the damaged part. Check whether there is a gas leakage phenomenon and take measures for the specific situation. Replace the air pipe if it is damaged.

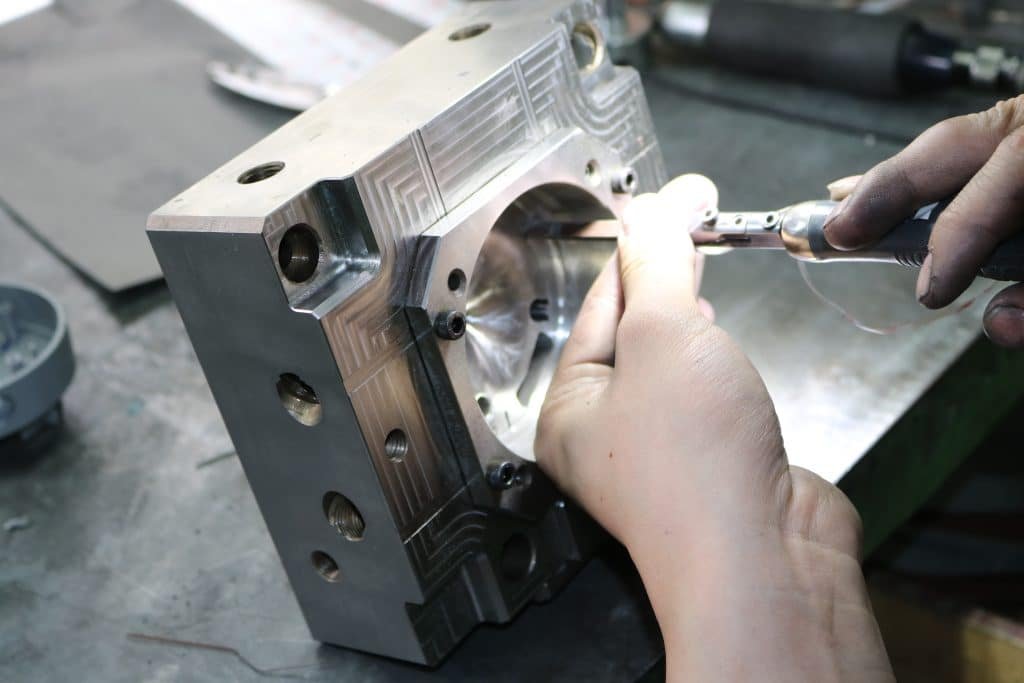

Enhancing Plastic Mold Accuracy & Durability

After producing plastic molds, pay attention to cleaning and maintenance to ensure the accuracy and life of the mold. The following points need to be noted:

1. Clean mold surface and cavity.

2. Clean the exhaust tank.

3. Clean the cooling water channel of the mold and check its sealing condition.

4. Check the seal of the hydraulic system.

5. Disassemble and pull the core, clean and lubricate.

6. Disassemble the slider and clean and lubricate it.

7. Disassemble the ejector block and clean and lubricate it.

8. Overhaul the mold ejector mechanism.

9. Check the fit of the parting surface of the mold.

10. Check whether the guide is loose and lubricated.

11. Clean the water channel with the cleaning agent, and then use an air gun to clean the impurities in the cooling channel. Dry with hot air.

12. If the mold is not used for a long time, the mold should be dried after the above maintenance. And coated with anti-embroider oil, the final mold should be stored in a dry place.

The effective maintenance of metal stamping parts and plastic molds requires the comprehensive use of a variety of methods and technologies, through the development of a reasonable maintenance plan, regular inspection and maintenance, record maintenance data, training staff, and other means, not only can improve production efficiency, but also extend the service life of the equipment, to ensure product quality.