Introduction

PVC is one of the most widely used plastics in the world, prized for its versatility, durability, and cost-effectiveness. This blog post will delve into the world of PVC, exploring what it is, the different types of PVC plastics, the various manufacturing processes, and the environmental impact and recycling of PVC materials.

What Is PVC Materials?

Polyvinyl Chloride, commonly known as PVC, is a synthetic plastic polymer made from the polymerization of vinyl chloride. PVC is known for its durability, chemical resistance, and versatility, making it suitable for a wide range of applications, from construction materials to medical devices.

PVC can be produced in two basic forms:

- Rigid PVC: Used for pipes, windows, and doors.

- Flexible PVC: Used for cables, flooring, and soft products through the addition of plasticizers.

Its ability to be mixed with various additives gives it unique properties, making PVC a preferred choice in numerous industries.

The Different Types Of PVC Plastic Materials

PVC plastics can be broadly classified into three types based on their formulation and properties:

| Type of PVC | Characteristics | Common Applications |

| Rigid PVC (uPVC) | High strength, rigid, excellent chemical resistance, low cost | Pipes, window frames, profiles, credit cards |

| Flexible PVC | Soft, flexible, good insulation properties, resistant to abrasion | Cable insulation, flooring, medical tubing, seals |

| CPVC (Chlorinated PVC) | Improved thermal stability, better chemical resistance | Hot water pipes, industrial liquid handling, fire sprinkler systems |

Rigid PVC (uPVC) is unplasticized PVC, which means it does not contain added plasticizers. It is hard and durable, making it ideal for structural applications.

Flexible PVC is made by adding plasticizers, which make the material more flexible and softer. This type is used in applications where flexibility is required, such as in tubing, insulation, and certain fabrics.

Chlorinated PVC (CPVC) is PVC that has been chlorinated via a chlorination reaction. The added chlorine content in CPVC makes it more heat-resistant and suitable for hot water pipes and industrial fluid handling.

Different Types Of PVC Plastic Materials Manufacturing Processes

Several manufacturing processes are used to produce PVC products, each tailored to the specific type of PVC and its application:

| Manufacturing Process | Description | Suitable for |

| Extrusion | PVC resin is melted and formed into a continuous profile. | Pipes, window frames, cable insulation, siding |

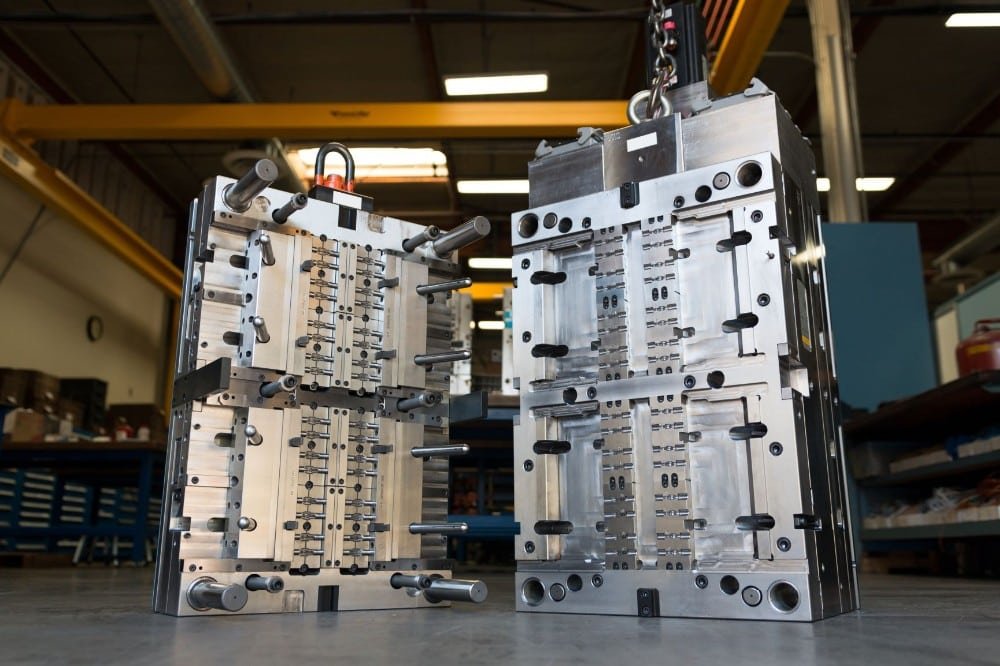

| Injection Molding | Molten PVC is injected into a mold to form intricate shapes. | Fittings, valves, toys, containers |

| Blow Molding | PVC is melted and extruded into a parison, which is then blown into a mold. | Bottles, hollow containers, automotive parts |

| Calendaring | PVC is rolled into thin sheets or films. | Floor coverings, wall coverings, synthetic leather |

| Coating and Dipping | PVC is dissolved or melted and then applied to a surface or dipped to form a coating. | Gloves, tool handles, fabric coatings |

- Extrusion: In this process, PVC resin is heated and melted, then pushed through a die to create continuous shapes like pipes, tubes, or window frames. This method is particularly suited for products that require long lengths and uniform cross-sections.

- Injection Molding: This process involves injecting molten PVC into a mold cavity to form complex shapes and designs. Injection molding is ideal for producing items like pipe fittings, containers, and various automotive parts.

- Blow Molding: PVC is heated and extruded into a parison (a tube-like piece), which is then inflated into a mold to create hollow objects such as bottles and tanks.

- Calendaring: In this process, PVC is passed through heated rollers to create thin sheets or films. Calendaring is commonly used to make products like vinyl flooring, shower curtains, and synthetic leather.

- Coating and Dipping: PVC can be melted or dissolved and then applied as a coating on other materials. This process is used to make products like protective gloves and coated fabrics.

Environmental Impact and Recycling of PVC Materials

PVC’s production, use, and disposal raise significant environmental concerns due to its chemical composition and additives. However, the recycling of PVC can help mitigate some of these impacts:

- Production Impact: The production of PVC involves chlorine, which can produce toxic byproducts like dioxins. The presence of plasticizers and stabilizers (like lead or cadmium) in some PVC materials can also be hazardous.

- Usage Impact: During use, PVC products are generally stable and safe. However, when burned or exposed to high temperatures, PVC can release toxic fumes.

- Recycling: PVC is highly recyclable and can be mechanically recycled to produce new products. Here’s a comparison of different recycling methods:

| Recycling Method | Description | Advantages | Challenges |

| Mechanical Recycling | Physical reprocessing of PVC waste into new products. | Reduces landfill waste, conserves resources | Requires separation and sorting of PVC types |

| Feedstock Recycling | Chemical breakdown of PVC into its basic chemicals for reuse. | Can handle mixed plastic waste, produces raw materials | Releases harmful emissions requires strict controls |

| Energy Recovery | Incineration of PVC waste to generate energy. | Reduces waste volume, generates energy | Releases harmful emissions, requires strict controls |

- Mechanical Recycling: This is the most common form of recycling for PVC, where waste material is collected, sorted, cleaned, and then reprocessed into granules that can be used to manufacture new products.

- Feedstock Recycling: This method involves breaking down PVC into its constituent chemicals, which can then be used as feedstock for new PVC production or other chemical processes.

- Energy Recovery: PVC waste can be incinerated to produce energy. However, this process must be carefully managed to control emissions of toxic substances.

Top 10 FAQs About PVC Materials

1. What are the key types of PVC materials used in industrial applications?

PVC materials are categorized into rigid PVC (uPVC) for pipes/window frames and flexible PVC for cables/hoses. Specialty types include chlorinated PVC (CPVC) for high-temperature resistance and PVC foam for lightweight structural applications.

2. What certifications should PVC materials suppliers comply with?

Ensure suppliers meet ISO 9001 (quality), UL 94 (flammability), RoHS/REACH (chemical safety), and NSF/ANSI 61 (potable water compliance) for critical applications like plumbing or medical devices.

3. How does the PVC manufacturing process impact material performance?

PVC production involves suspension polymerization (most common), emulsion polymerization (fine powders), or bulk polymerization. The process affects properties like tensile strength (10–50 MPa) and heat resistance (60–93°C).

4. What additives are critical for enhancing PVC materials properties?

- Plasticizers: DINP or DEHP for flexibility.

- Stabilizers: Calcium-zinc or lead-based (phasing out) for thermal stability.

- Flame retardants: Antimony trioxide for UL 94 V-0 compliance.

5. What are the cost drivers for PVC materials production?

- Raw materials: Ethylene and chlorine prices fluctuate with oil markets.

- Energy consumption: 8–12 kWh per kg of PVC produced.

- Additives: Specialty stabilizers or plasticizers add 15–30% to costs.

6. How do I evaluate PVC suppliers for consistent quality?

- Request batch test reports (melt flow index, tensile strength).

- Audit traceability systems for raw materials.

- Verify in-house compounding capabilities to ensure additive uniformity.

7. Can recycled PVC materials meet industrial performance standards?

Yes, post-consumer recycled PVC (rPVC) can achieve 80–90% of virgin material properties when blended with stabilizers. Ensure suppliers comply with ASTM D6868 or EN 15343 recycling standards.

8. What environmental regulations impact PVC material selection?

- EU PVC Waste Directive: Requires 70%+ recycling rates for construction PVC.

- California Prop 65: Limits phthalate content (<0.1%).

- Green Building Certifications: LEED or BREEAM prefer low-VOC PVC formulations.

9. How do temperature and UV exposure affect PVC material lifespan?

- Heat aging: PVC loses 10–20% tensile strength after 1,000 hours at 70°C.

- UV degradation: Additives like titanium dioxide extend outdoor lifespan to 20–30 years.

10. What customization options do PVC suppliers offer?

- Color matching: Pantone or RAL standards with ±2% tolerance.

- Sheet/rod fabrication: Thicknesses from 0.5mm to 50mm.

- Anti-static/conductive grades: Surface resistivity down to 10³–10⁶ Ω/sq.

Conclusion

PVC is a versatile material that serves a broad range of applications due to its customizable properties. Understanding the different types of PVC, the manufacturing processes involved, and the environmental impact can help manufacturers and consumers make more informed decisions about using PVC.

About BFY Mold

PVC Plastic Injection Molding

At BFY Mold, we specialize in delivering high-quality injection molding and mold manufacturing services. With a strong commitment to precision and efficiency, we offer mass production, low-volume manufacturing, CNC machining, and mirror spark finishing—all from our state-of-the-art factory. Our expertise in using various materials, including PVC, ensures that we can meet your specific requirements with innovative solutions. Choose BFY Mold for your next project and experience manufacturing excellence.