When it comes to producing high-quality plastic parts, choosing the right injection molding company is crucial. The expertise and capabilities of an injection molding provider can significantly impact product quality, production efficiency, and overall costs. In this guide, we’ll explore the key factors to consider when selecting an injection molding company, their services, and how to ensure they meet your specific production needs.

What is Injection Molding?

Injection molding is a manufacturing process used to produce plastic parts by injecting molten material into a mold. This process is widely used in various industries due to its ability to create high-precision parts in large volumes at a relatively low cost. A wide range of materials, including thermoplastics, thermosetting polymers, metals, and glass, can be used in the injection molding process.

Benefits of Injection Molding

Injection molding offers numerous advantages, including:

- Cost efficiency for mass production: Ideal for producing large quantities of parts quickly.

- Design flexibility: Complex designs can be easily molded with high precision.

- Material variety: A wide selection of materials can be used.

- Consistency: Uniform parts are produced with tight tolerances.

Key Factors to Consider When Choosing an Injection Molding Company

Choosing the right injection molding company is a critical decision. Here are some important factors to consider:

1. Experience and Expertise

The experience of an injection molding company plays a vital role in ensuring the success of your project. An experienced company will deeply understand the injection molding process, allowing them to produce parts with high precision, minimize production errors, and provide valuable insights during the design phase.

How to Assess Expertise:

- Years in business: Established companies have a proven track record of delivering quality.

- Industry specialization: Some companies specialize in specific industries like automotive, medical, or consumer products.

- Portfolio: Review the company’s past projects to ensure they have experience producing parts similar to yours.

2. Manufacturing Capabilities

Not all injection molding companies offer the same range of services or manufacturing capabilities. Ensure the company you choose can handle your production needs, from prototyping to large-scale manufacturing.

Consider the Following Capabilities:

- Production volume: Does the company offer both small and large batch production?

- Material selection: Does the company have experience with the type of material required for your parts?

- Machine capacity: Ensure they have the right equipment to handle the size and complexity of your product.

3. Quality Control Measures

A reliable injection molding company should have strict quality control measures in place to ensure that each part meets your specifications. Quality control protocols help to avoid defects, inconsistencies, and other issues that could compromise the integrity of your products.

Key Quality Control Practices:

- In-house testing and inspection: Does the company perform regular tests and inspections during production?

- ISO certification: Many top-tier injection molding companies are ISO certified, demonstrating their commitment to quality.

- Quality assurance protocols: Look for companies that follow industry best practices for quality assurance.

4. Cost Considerations

While cost shouldn’t be the sole factor in your decision-making process, it’s essential to understand the pricing structure of the injection molding company. Be sure to get a detailed breakdown of costs, including setup fees, material costs, and production costs.

Factors That Influence Cost:

- Material selection: Some materials are more expensive than others.

- Tooling costs: Initial mold creation can be costly but is a one-time investment.

- Production volume: Larger production runs often result in lower per-unit costs.

5. Lead Time and Production Speed

Time is a critical factor in manufacturing. If you’re working under a tight deadline, make sure the company can meet your production schedule. Ask about their average lead times and ensure they have the capacity to handle your order without delays.

Questions to Ask About Lead Time:

- What is the company’s average turnaround time?

- Do they offer expedited services for urgent projects?

- How do they manage production schedules to avoid delays?

6. Customer Support and Communication

Effective communication is essential throughout the injection molding process, from initial design to final delivery. A company that offers strong customer support will keep you updated on project progress, respond to inquiries promptly, and provide solutions to any challenges that arise.

How to Evaluate Customer Support:

- Availability: Is the company accessible and responsive to your questions?

- Collaboration: Do they offer design consultation and engineering support?

- Problem-solving: How do they handle issues such as production delays or defects?

7. Sustainability Practices

With growing concerns over environmental impact, it’s important to choose a company that follows sustainable practices. Many injection molding companies are adopting eco-friendly materials, energy-efficient production processes, and recycling programs to reduce their environmental footprint.

Sustainable Practices to Look For:

- Recycled materials: Does the company use recycled plastics in their production?

- Energy-efficient processes: Do they implement energy-saving techniques during manufacturing?

- Waste reduction: How do they minimize waste in the production process?

Services Offered by Injection Molding Companies

The services provided by injection molding companies can vary, so it’s important to choose one that offers a comprehensive range of solutions to meet your needs.

1. Injection Molding and Mold Manufacturing

Injection molding companies typically offer mold manufacturing services to create custom molds based on your product design. These molds are then used in the production process to create plastic parts.

2. Mass Production and On-Demand Production

Whether you need high-volume mass production or smaller on-demand batches, many companies offer flexible production options to accommodate different quantities and timelines.

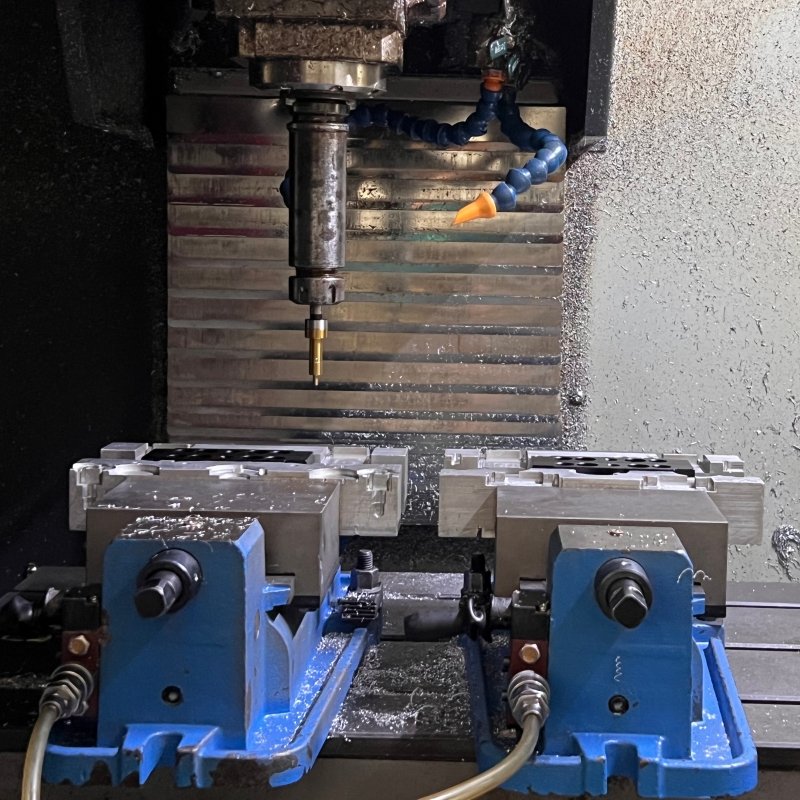

3. CNC Machining

Some injection molding companies also offer CNC machining services for creating prototypes, tooling, and complex components with high precision.

4. Mirror Spark

Mirror spark technology is used for polishing molds to achieve a high-gloss finish, ensuring smooth surfaces on the final plastic parts.

Conclusion

Choosing the right injection molding company requires careful consideration of various factors, including expertise, capabilities, quality control measures, cost, and sustainability practices. By evaluating these aspects, you can find a reliable partner that will help bring your product to life with high quality and efficiency.

About BFY Mold

BFY Mold is a leading provider of injection molding and mold manufacturing services, offering a wide range of solutions, including mass production, on-demand production, CNC machining, and mirror spark technology. With our factory and a team of experienced professionals, we are committed to delivering high-quality plastic parts that meet your specifications. Trust BFY Mold for your next project, whether you need prototypes, small batches, or large-scale production runs.