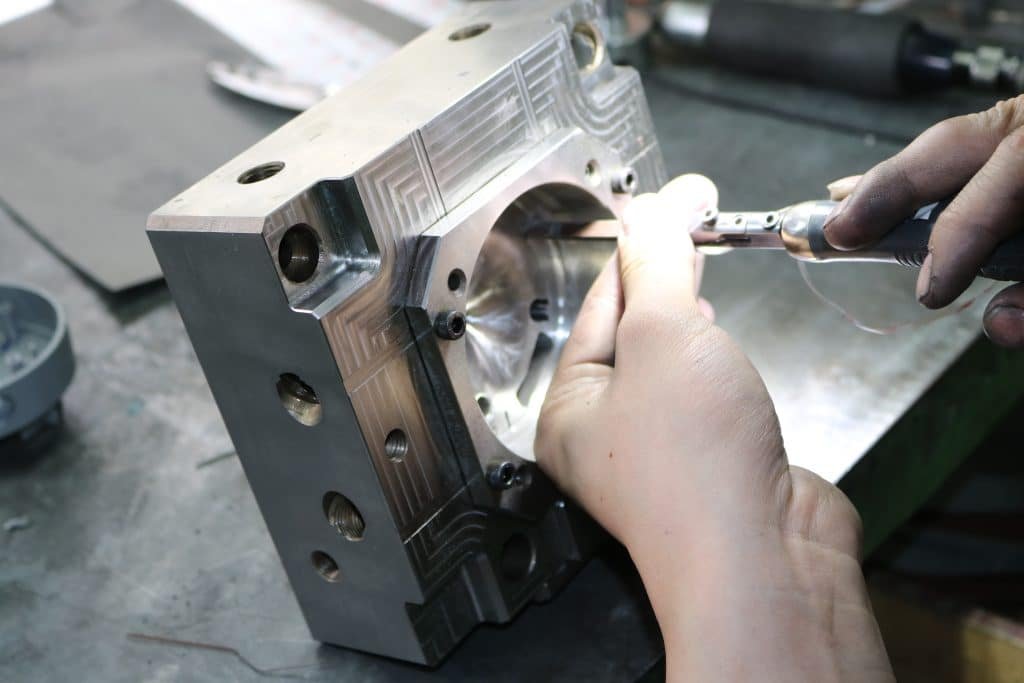

Injection mold surfaces are polished using various tools to achieve a mirror-like finish, a process known as polishing. The tools commonly used for injection mold polishing include whetstones, sandpaper, polishing pastes, wool wheels, etc. For achieving high-quality polishing results, it is advisable to opt for premium-grade polishing tools and auxiliary products such as whetstones, sandpaper, and diamond grinding paste.

The choice of polishing technique depends on the surface condition following initial processing steps such as machining, EDM, grinding, etc. So, how to polish injection molds? The general mechanical polishing process entails the following steps:

1. Rough Polishing

After milling, EDM, grinding, or similar processes, the surface can be polished using a rotating surface polishing machine or an ultrasonic grinder with a rotational speed of 35,000-40,000 rpm. A common method involves eliminating the white EDM layer using a wheel with a diameter of Φ3mm and WA #400. Subsequently, manual grinding with whetstones is performed using a strip of whetstone lubricated or cooled with kerosene. The typical sequence includes #180 ~ #240 ~ #320 ~ #400 ~ #600 ~ #800 ~ #1000. To save time, many mold manufacturers start directly with #400.

2. Semi-Finished Polishing

Semi-finished polishing primarily utilizes sandpaper and kerosene. The sandpaper sequence comprises #400 ~ #600 ~ #800 ~ #1000 ~ #1200 ~ #1500. However, it’s worth noting that #1500 sandpaper is suitable only for hardened die steel (52HRC and above), not for pre-hardened steel, as it may cause surface burns on the latter.

3. Fine Polishing

Fine polishing predominantly involves diamond grinding paste. When mixed with a polishing cloth wheel, the typical grinding sequence consists of 9μm (#1800) ~ 6μm (#3000) ~ 3μm (#8000). A 9μm diamond abrasive paste and polishing cloth wheel can effectively remove hallmarks left by #1200 and #1500 sandpaper. Subsequently, polishing with sticky felt and diamond grinding paste follows, with a sequence of 1μm (#14000) ~ 1/2μm (#60000) ~ 1/4μm (#100000).

Injection mold polishing processes requiring precision above 1μm (including 1μm) are conducted in a clean polishing room within the mold processing workshop. For utmost precision, an impeccably clean environment is indispensable. Dust, smoke, dandruff, or droplets can compromise the meticulously polished surface achieved after hours of labor.