Enhancing US Businesses Production Efficiency with Injection Molding from China

In today’s competitive global marketplace, businesses must find innovative ways to improve production efficiency, reduce costs, and maintain high-quality standards. For many US businesses, injection molding from China has emerged as a strategic solution for achieving these goals. By leveraging China’s advanced manufacturing capabilities, skilled workforce, and cost advantages, companies can enhance their production processes and gain a competitive edge.

The Growing Demand for Injection Molding in the US

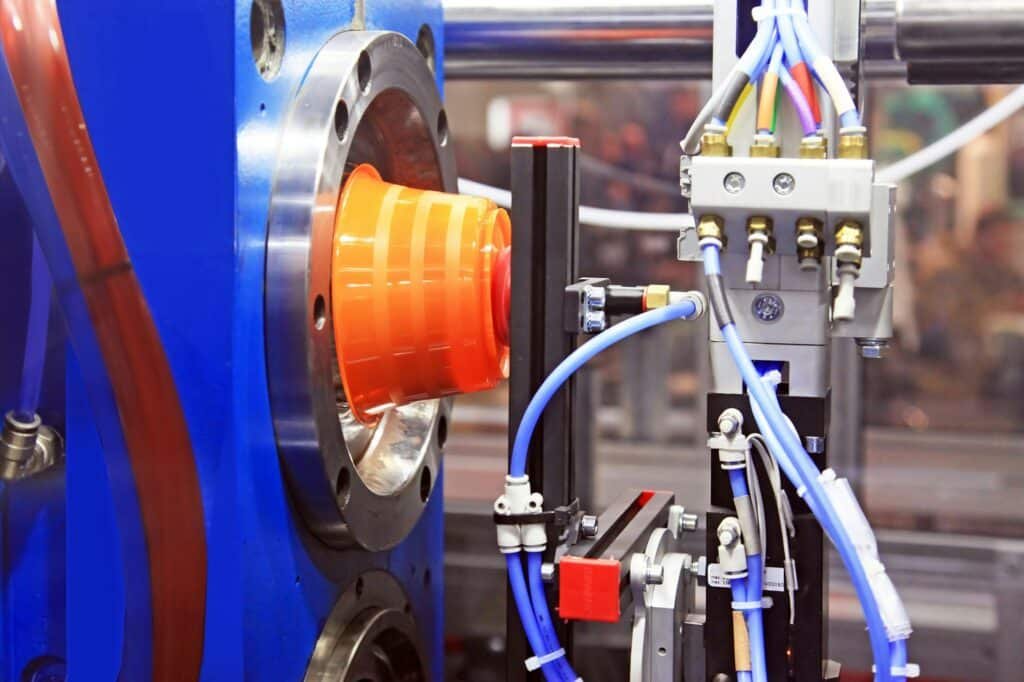

Injection molding has become a cornerstone for the automotive, medical devices, consumer goods, and electronics industries. This process offers unparalleled precision, scalability, and speed, making it essential for producing everything from intricate components to large-scale products. However, the rising production costs in the US have pushed businesses to explore offshore options, particularly in China.

China has become a global leader in injection molding, offering a unique blend of advanced technology and cost-effective solutions. The country’s robust infrastructure and expertise in mold manufacturing make it an attractive choice for US companies looking to optimize production.

Why Choose Injection Molding from China?

- Cost-Effectiveness

One of the primary reasons US businesses turn to China for injection molding is cost savings. Labor costs, material sourcing, and operational expenses are significantly lower in China, allowing companies to produce high-quality parts at a fraction of the price. - Access to Advanced Technology

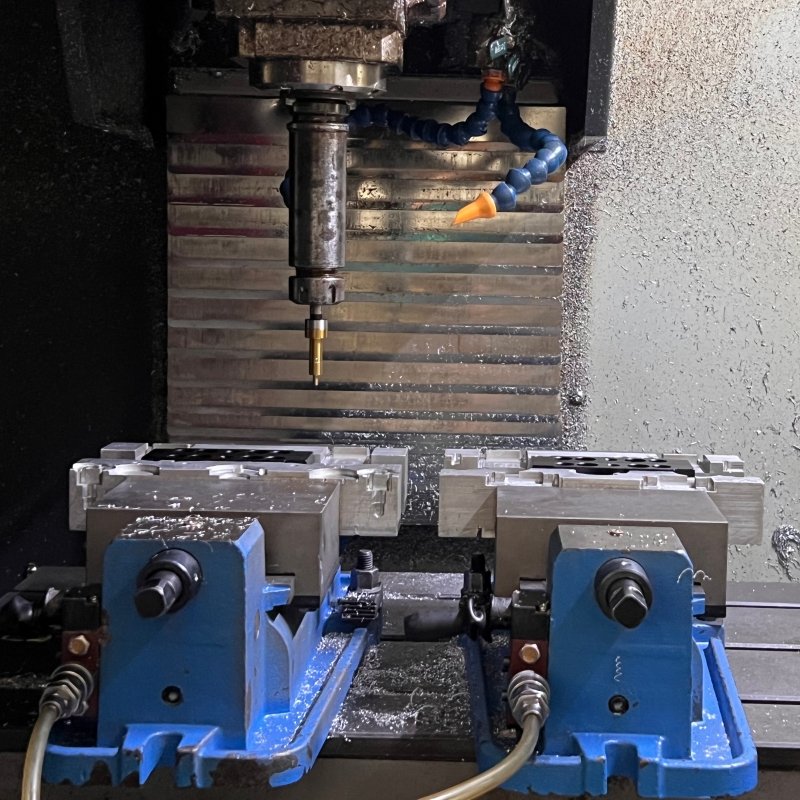

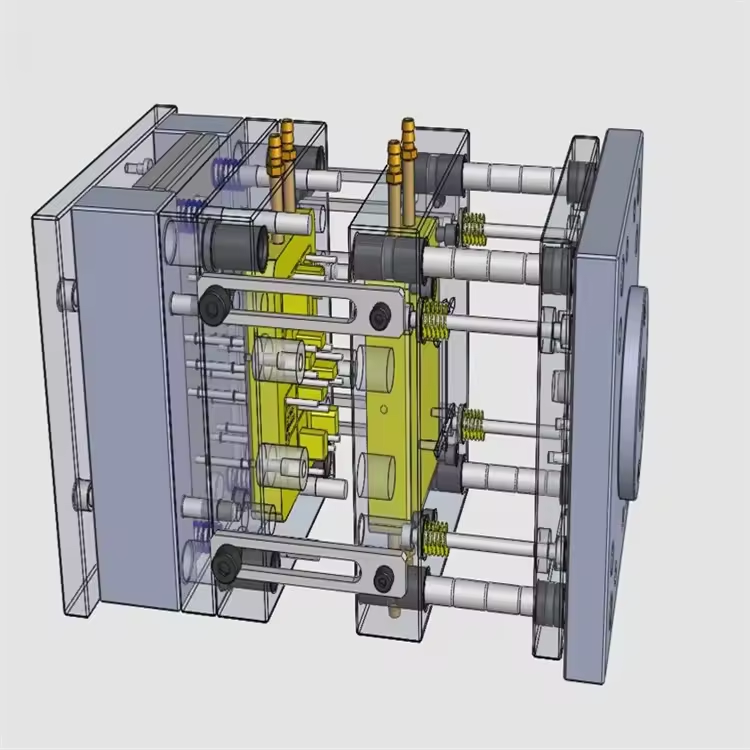

Chinese manufacturers like BFY Mold utilize state-of-the-art equipment, including CNC machining and mirror spark technology, to deliver precision and consistency. This ensures that products meet stringent quality standards, even for the most complex designs. - Scalability for Mass Production

Whether a business requires thousands or millions of units, Chinese injection molding facilities can handle large-scale production without compromising quality. - Faster Time-to-Market

With efficient manufacturing processes and streamlined logistics, Chinese manufacturers can produce and deliver products quickly, helping US companies reduce lead times and stay competitive in their industries. - Customizable Solutions

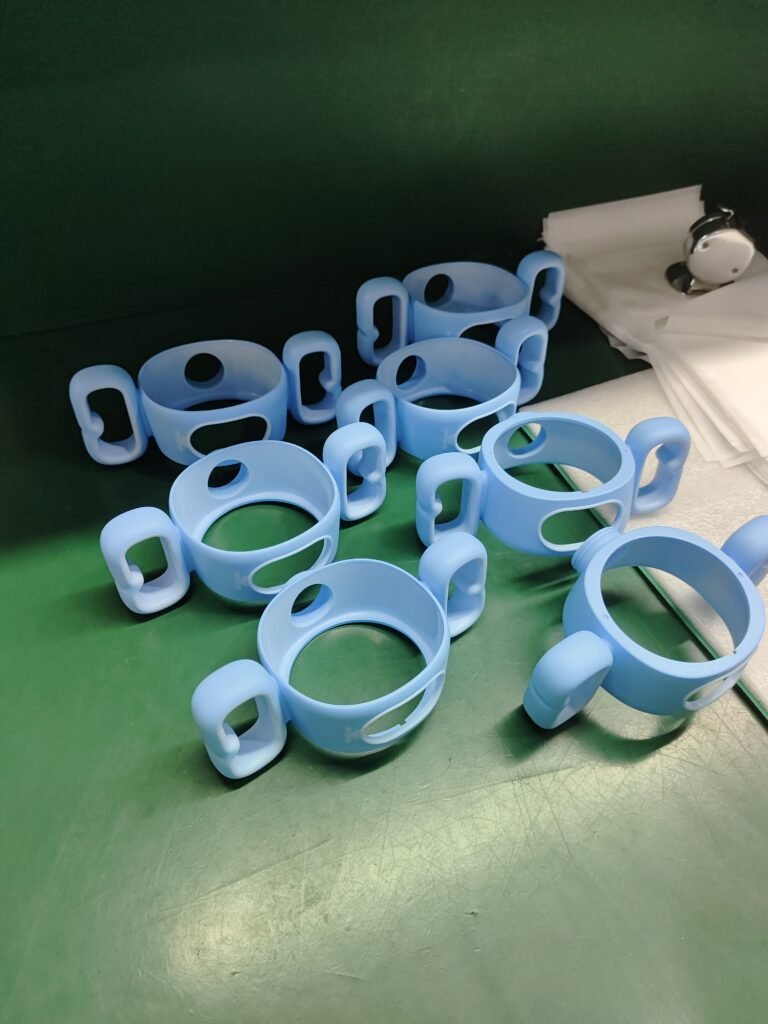

Custom injection molding allows businesses to create tailored products that meet specific design requirements. Chinese manufacturers offer comprehensive solutions to meet diverse needs from prototypes to final production.

How Injection Molding from China Boosts US Business Efficiency

- Streamlined Supply Chain

Collaborating with Chinese manufacturers simplifies the supply chain by combining multiple production processes under one roof. This reduces the need for coordinating with multiple vendors, saving time and resources. - Improved Resource Allocation

By outsourcing injection molding to China, US companies can focus on their core competencies such as design, marketing, and distribution, while leaving the manufacturing to experts. - Enhanced Product Quality

Advanced inspection techniques and stringent quality control measures ensure that products manufactured in China meet global standards, enhancing customer satisfaction and brand reputation. - Flexibility for On-Demand Production

For businesses with fluctuating production needs, Chinese manufacturers offer on-demand production services, enabling them to scale production up or down as required without incurring excessive costs.

Key Considerations for Partnering with Chinese Injection Molding Providers

While injection molding from China offers numerous benefits, businesses should consider the following factors to ensure a successful partnership:

- Quality Assurance

Ensure the manufacturer adheres to international quality standards such as ISO certifications. Partnering with companies like BFY Mold guarantees precision and reliability. - Communication and Transparency

Clear communication is essential for avoiding misunderstandings and ensuring that the final product aligns with expectations. Work with manufacturers who provide regular updates and transparent pricing. - Intellectual Property Protection

Protecting proprietary designs is crucial. Choose reputable manufacturers who prioritize intellectual property security and comply with legal agreements. - Logistics and Shipping

Factor in shipping times and costs to ensure timely delivery. Many Chinese manufacturers have established logistics networks to facilitate smooth international shipping.

Industries Benefiting from Injection Molding in China

- Automotive

From engine components to interior trims, Chinese injection molding supports the automotive industry with durable and precision-engineered parts. - Medical Devices

The high standards of Chinese manufacturers make them ideal for producing medical devices and components, ensuring safety and compliance. - Consumer Goods

Mass production capabilities and cost efficiency make injection molding in China a preferred choice for producing household items, packaging, and electronics. - Electronics

Injection molding is essential for creating casings, connectors, and other intricate components in the electronics sector, where precision is paramount.

Future Trends in Injection Molding from China

The injection molding industry continues to evolve, with innovations such as:

- Sustainable Practices

Many Chinese manufacturers are adopting eco-friendly practices, such as using recycled materials and energy-efficient processes, to align with global sustainability goals. - Automation and AI Integration

Advanced robotics and AI are improving production efficiency, reducing errors, and lowering costs further. - Rapid Prototyping

Enhanced prototyping capabilities allow businesses to test designs and bring products to market faster.

10 FAQs to Improve Production Efficiency

1. How can suppliers help reduce production downtime?

Reliable suppliers offer predictive maintenance programs, real-time equipment monitoring, and rapid spare parts delivery. Partnering with a vendor that provides IoT-enabled machinery can reduce unplanned downtime by 20–30%.

2. What technologies do suppliers use to optimize production workflows?

Top suppliers leverage:

- AI-driven process control to minimize defects.

- Automated material handling systems to reduce human error.

- Digital twins for simulating and refining production lines.

3. How do you ensure consistent raw material quality to improve output?

Suppliers should provide:

- Certificates of Analysis (CoA) for every batch.

- ISO 9001 certification for quality management.

- Supplier audits to verify material traceability and compliance.

4. What strategies do suppliers employ to reduce production costs?

- Lean manufacturing to eliminate waste (e.g., Toyota Production System).

- Bulk purchasing agreements for discounted raw materials.

- Energy-efficient equipment cutting utility costs by 15–25%.

5. How can suppliers help scale production without compromising quality?

Look for partners offering:

- Modular production lines for flexible capacity adjustments.

- Multi-shift operations to handle demand spikes.

- Six Sigma or Kaizen methodologies to maintain quality at scale.

6. What certifications indicate a supplier’s ability to improve production sustainability?

- ISO 14001 (environmental management).

- R2/RIOS for responsible electronics recycling.

- Energy Star for energy-efficient machinery.

7. How do suppliers address supply chain disruptions to ensure uninterrupted production?

- Dual sourcing for critical components.

- Safety stock programs for high-demand materials.

- Blockchain tracking for real-time supply chain visibility.

8. What role does data analytics play in improving production outcomes?

Advanced suppliers use analytics to:

- Predict machine failures (85% accuracy with AI models).

- Optimize inventory turnover rates.

- Identify bottlenecks reducing throughput by 10–15%.

9. How do suppliers ensure compliance with industry-specific production standards?

- Automotive: IATF 16949 certification.

- Medical: ISO 13485 and FDA 21 CFR Part 820 compliance.

- Aerospace: AS9100 Rev D standards.

10. What post-production support do suppliers offer to maintain efficiency?

- Training programs for equipment operation and maintenance.

- Remote diagnostics to troubleshoot issues in real-time.

- Warranty extensions covering critical machinery components.

Conclusion

Injection molding from China offers US businesses a powerful way to improve production efficiency, reduce costs, and maintain high-quality standards. By leveraging the expertise and advanced capabilities of Chinese manufacturers, companies can streamline their processes and achieve greater profitability.

About BFY Mold

At BFY Mold, we specialize in providing high-quality injection molding and mold manufacturing solutions. With our one-stop production factory, we offer services tailored to meet diverse production needs, including mold manufacturing, mass production, on-demand production, CNC machining, and mirror spark finishing. Our commitment to precision and efficiency ensures that we deliver exceptional results for businesses across various industries. Partner with BFY Mold to elevate your production capabilities and achieve success in today’s competitive market.