Introduction

The demand for injection molding in smart home products is rapidly increasing as consumers seek greater convenience, security, and energy efficiency. From smart lighting to advanced security systems, these devices are transforming our daily lives. Central to the production of these innovative products is injection molding, a manufacturing process that enables the creation of intricate plastic components.

Growing Demand for Smart Home Products

Trends in ConsumeIntegrating electronics within plastic components demands advanced design capabilities to ensure r Preferences

- Convenience: Automation technologies are increasingly appealing to consumers who prioritize time-saving solutions.

- Security: Smart devices enhance home safety, offering real-time monitoring and alerts.

- Energy Efficiency: Products designed to optimize energy use are becoming essential in modern households.

Key Smart Home Products and Their Features

| Product Type | Key Features | Popular Brands |

| Smart Thermostats | Remote control, adaptive scheduling | Nest, Ecobee |

| Smart Lights | Voice control, customizable ambiance | Philips Hue, LIFX |

| Security Cameras | HD video, motion detection | Ring, Arlo |

| Smart Speakers | Voice commands, integration with devices | Amazon Echo, Google Nest |

The Role of Injection Molding

Advantages of Injection Molding in Smart Home Products

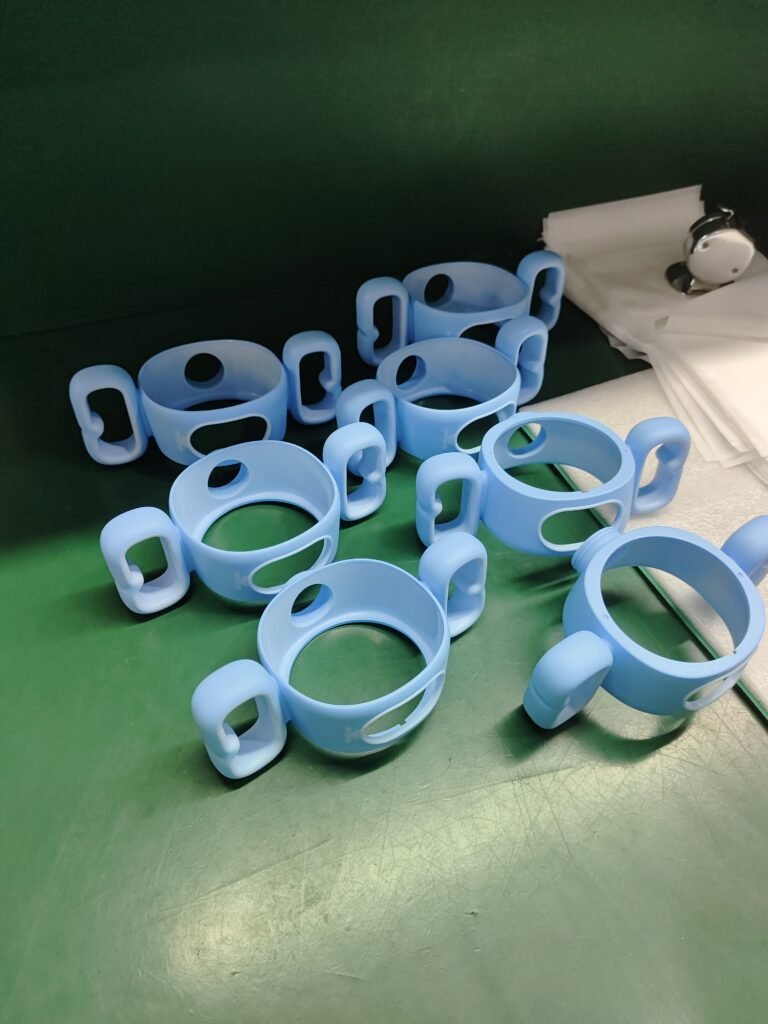

Injection molding is pivotal in producing smart home products due to several key benefits:

- Cost-Effectiveness: Once molds are created, producing large quantities becomes efficient, reducing costs per unit significantly.

- Versatility: Manufacturers can easily switch between different materials and designs, allowing for rapid adaptation to market trends.

- Detailing: The ability to create intricate shapes and fine features enhances product aesthetics and functionality.

Challenges in Design and Production

While injection molding offers numerous advantages for the production of smart home products, it also presents several challenges that manufacturers must navigate to ensure successful outcomes.

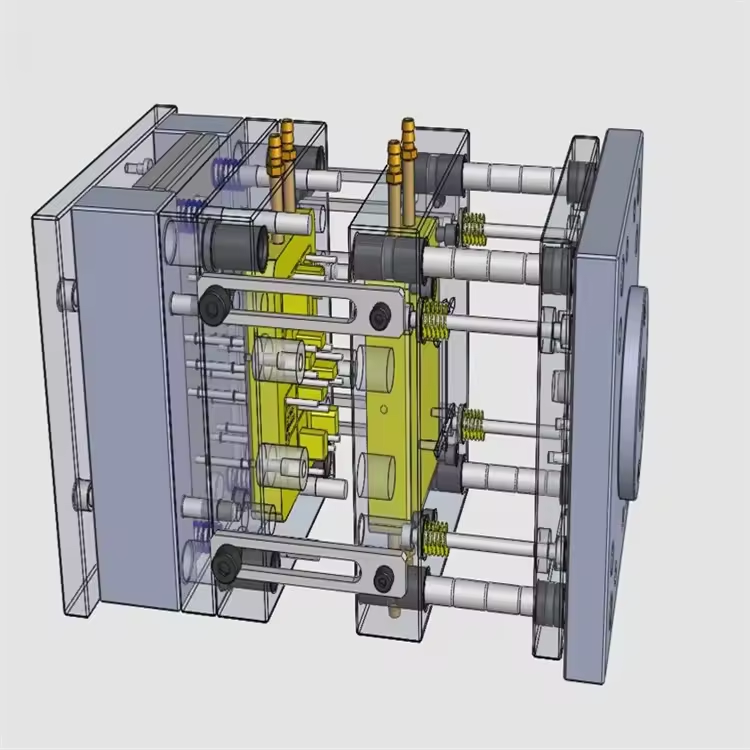

Design Complexity

The integration of electronics within plastic components demands advanced design capabilities. Designers must create molds that not only accommodate the intricate shapes and features of smart devices but also allow for the seamless integration of electronic components. This complexity often requires iterative design processes, which can be time-consuming and costly. Additionally, the need for aesthetics—ensuring that the final product is visually appealing—complicates the design process further.

Material Selection

Choosing the right materials is crucial for the performance and durability of smart home devices. Manufacturers must balance factors such as strength, flexibility, and thermal resistance, while also considering the visual aspects of the material. The growing demand for sustainable options adds another layer of complexity to material selection, requiring manufacturers to explore eco-friendly alternatives without compromising quality.

Quality Control Measures

Maintaining high-quality standards is essential, especially with the precision required for electronic components. The manufacturing process must include rigorous testing protocols to ensure that each component meets specific tolerances and performance criteria. Any deviation in quality can lead to failures in the final product, affecting both reliability and customer satisfaction. Establishing effective quality control measures is crucial to minimizing defects and ensuring that products perform as intended.

Benefits of Injection Molding in Smart Home Products

Cost Efficiency

The initial investment in mold creation is offset by the high efficiency of mass production. This not only lowers costs but also enables competitive pricing for consumers.

Versatility and Adaptability

Manufacturers can respond quickly to changing consumer demands by altering designs and materials, enhancing their market agility.

Aesthetic Enhancements

Injection molding facilitates the production of visually appealing products, with detailed features that can influence consumer purchasing decisions.

Why Choose BFY Mold?

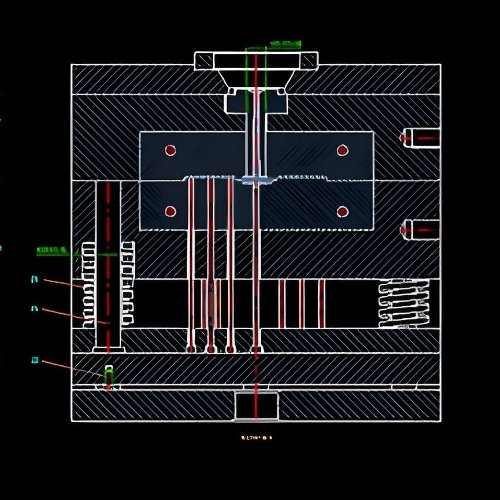

Expertise in Mold Design

At BFY Mold, we specialize in providing comprehensive services, from mold design to production, ensuring that each product meets the highest standards of quality.

Commitment to Quality

Our rigorous quality control processes guarantee that every component produced is durable and reliable, meeting the exact specifications required for smart home devices.

Collaborative Approach

We pride ourselves on working closely with clients to understand their specific needs and providing ongoing support throughout the manufacturing process.

BFY Mold Manufacturing Services

| Service | Description |

| Mold Design | Customized designs tailored to client specifications |

| Prototyping | Rapid prototyping for testing and validation |

| Mass Production | Efficient production of high-quality components |

| Quality Assurance | Thorough testing and inspection processes |

Conclusion

The intersection of smart home products and injection molding presents significant opportunities for innovation and growth in the manufacturing sector. By effectively addressing the challenges and harnessing the advantages of injection molding, businesses can thrive in this dynamic market. Partnering with BFY Mold ensures access to expertise, quality, and a commitment to customer satisfaction, empowering clients to focus on creating cutting-edge products that enhance modern living.