In manufacturing, efficiency, and scalability have long been the guiding principles. However, the traditional mass production model, while effective for large-scale operations, sometimes falls short regarding flexibility, customization, and cost-effectiveness for smaller batches. This is where low-volume manufacturing steps in as a pivotal solution.

Defining Low-volume Manufacturing:

Low-volume manufacturing refers to producing goods in small quantities, typically ranging from tens to a few thousand units, as opposed to the massive quantities associated with mass production. It stands at the intersection of customization and efficiency, offering a viable alternative to traditional manufacturing methods for businesses seeking flexibility, reduced inventory costs, and quicker time-to-market.

In today’s dynamic market landscape, where consumer preferences evolve rapidly, the ability to adapt and respond swiftly is paramount. Low-volume manufacturing facilitates this agility by allowing companies to test new products, iterate designs, and cater to niche markets without committing to large-scale production runs. This flexibility minimizes the risks associated with inventory surplus and obsolescence, enabling businesses to optimize resource allocation and maximize profitability.

Advantages of Low-volume Manufacturing

1. Flexibility:

It allows for greater flexibility in production processes compared to traditional mass production methods. It enables businesses to quickly adapt to changing market demands, customize products to meet specific requirements, and introduce new designs or variations without significant retooling or setup costs. This agility is particularly beneficial for industries where product lifecycles are short or where customers value customization.

2. Cost-effectiveness:

While mass production often requires large capital investments in machinery, tooling, and infrastructure, it can be more cost-effective, especially for smaller production runs. By producing smaller quantities, businesses can minimize inventory holding costs, reduce the risk of overproduction, and avoid excess waste. Additionally, it allows for more efficient use of resources, as production processes can be tailored to match demand more closely.

3. Faster Time-to-Market:

Low-volume manufacturing enables faster time-to-market for new products or product iterations. With shorter setup times and less complex production processes, businesses can rapidly prototype, test, and refine designs before scaling up production. This speed-to-market advantage is crucial for staying ahead of competitors, capturing market opportunities, and meeting evolving customer needs promptly.

Applications Across Various Industries:

The versatility of low-volume manufacturing transcends industry boundaries, finding applications in sectors ranging from automotive and electronics to healthcare and consumer goods. In the automotive industry, for instance, it enables the production of specialty vehicles, prototypes, and custom parts tailored to individual preferences. Similarly, in the electronics sector, it facilitates the development of prototype circuit boards, small-batch production of innovative gadgets, and customization of electronic components to meet specific requirements.

In the realm of healthcare, low-volume manufacturing plays a pivotal role in the production of medical devices, prosthetics, and personalized pharmaceuticals. By catering to the unique needs of patients and healthcare professionals, it fosters innovation and enhances patient care. Moreover, in the consumer goods industry, it empowers brands to offer limited edition products, bespoke items, and niche market offerings, thereby fostering customer engagement and brand loyalty.

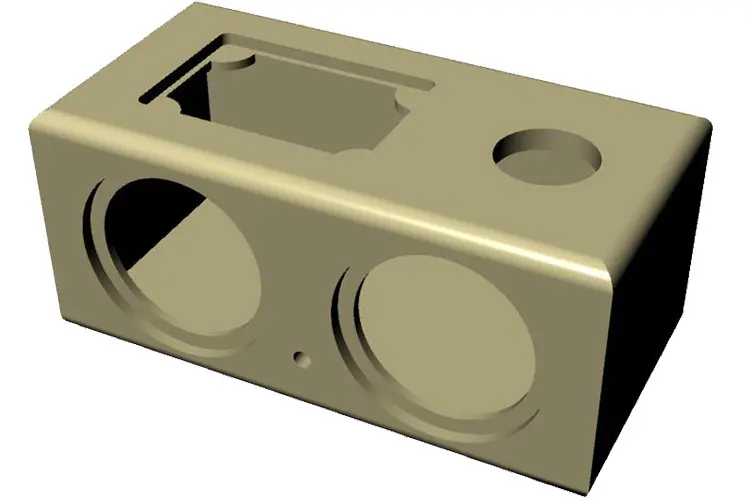

Future Prospects and Emerging Trends: As technology continues to advance and market dynamics evolve, the future of low-volume manufacturing appears promising. Additive manufacturing technologies, such as 3D printing, have revolutionized the landscape by enabling cost-effective production of complex geometries and customized components with minimal setup time. This transformative capability opens new avenues for innovation and creativity, driving the adoption across diverse industries.

Furthermore, advancements in digital manufacturing, automation, and supply chain management are enhancing the efficiency and scalability of low-volume production processes. By leveraging data analytics, artificial intelligence, and machine learning algorithms, manufacturers can optimize production schedules, predict demand fluctuations, and streamline logistics operations, thereby reducing lead times and enhancing overall competitiveness.

Moreover, the growing emphasis on sustainability and environmental stewardship is reshaping the manufacturing paradigm, prompting companies to explore eco-friendly materials, energy-efficient processes, and waste reduction strategies. It aligns well with these sustainability objectives by minimizing material waste, energy consumption, and carbon emissions associated with traditional mass production methods.

FAQs on Low-Volume Manufacturing

1. Is low-volume manufacturing more expensive than mass production? How can costs be optimized?

Low-volume manufacturing typically has higher per-unit costs due to fixed expenses (e.g., tooling, setup) being spread across fewer units. However, you can optimize costs by:

- Simplifying designs to reduce tooling complexity.

- Using standard materials (e.g., ABS, PP) to avoid speciality sourcing.

- Leveraging flexible techniques like 3D printing or silicone molds to lower upfront investments.

- Batch combining multiple designs in a single production run to share resources.

2. What is the typical lead time for low-volume production? Can orders be expedited?

Lead times range from 2–6 weeks, depending on complexity (e.g., CNC machining: 1–2 weeks; injection molding with tooling: 3–6 weeks). Expedited services are available (10–30% surcharge) through:

- Pre-certified materials to accelerate procurement.

- Modular molds for rapid design changes.

- Parallel workflows (e.g., concurrent quality checks and packaging).

3. What materials are supported for low-volume production? Are there limitations?

We work with a wide range of materials, including:

- Plastics: ABS, PC, nylon, PEEK (for high-temperature applications).

- Metals: Aluminum, stainless steel, titanium.

- Elastomers: TPU, silicone.

Limitations:

- High-performance materials (e.g., carbon fiber composites) may require minimum order quantities (MOQs).

- Custom colors or additives may extend lead times.

4. How do you ensure quality consistency in low-volume production?

Quality is ensured through:

- First Article Inspection (FAI): 100% inspection of initial samples for dimensional and functional accuracy.

- Process controls: Real-time monitoring of parameters (e.g., ±2°C injection molding temperature).

- Certifications: Compliance with ISO 9001/13485 (medical) standards.

- Traceability: Batch-specific test reports and production logs.

5. How can we transition from low-volume to mass production smoothly?

To scale efficiently:

- Design for Manufacturability (DFM): Optimize part geometry for high-volume tooling (e.g., simplify undercuts).

- Prototype validation: Test production samples under real-world conditions.

- Partner early: Collaborate with manufacturers to align tooling (e.g., multi-cavity molds) and material supply chains.

- Phased scaling: Gradually increase volumes while monitoring quality and costs.

Conclusion:

Low-volume manufacturing represents a paradigm shift in modern production dynamics, offering a compelling blend of flexibility, customization, and cost-effectiveness. Its significance spans across various industries, empowering businesses to innovate, adapt, and thrive in an increasingly competitive marketplace. As technology continues to advance and consumer expectations evolve, the future of low-volume manufacturing holds immense potential for driving innovation, sustainability, and economic growth on a global scale.