1. What Does Prototyping in Injection Molding Mean?

Injection molding prototyping refers to the process of producing an initial representation of a product using injection molding techniques. To test the design, functionality, and viability of a product, these prototypes are important. The main purpose is to create rapid prototypes that can be tested and validated, so engineers and designers can catch any potential issues early in the process.

Prototyping tools, unlike regular production tools, we are not operating at a commissioned level(Far in more quantity) and It’s mainly for testing purposes. This process helps speed up the product development timeline and minimize the possibility of costly design mistakes in mass-produced products.

Advantages of Prototyping in Injection Molding:

- Quicker Product Development: Prototyping accelerates the whole design process from a quick approach to testing.

- Economic: Prototyping is cost-efficient compared to complete production as it utilizes affordable materials and tools.

- Design Validation: Allowing designers to verify the form, fit, and function of the product before going to mass production prototypes can reduce time wastage.

2. What is an Injection Molding Prototyping Tool?

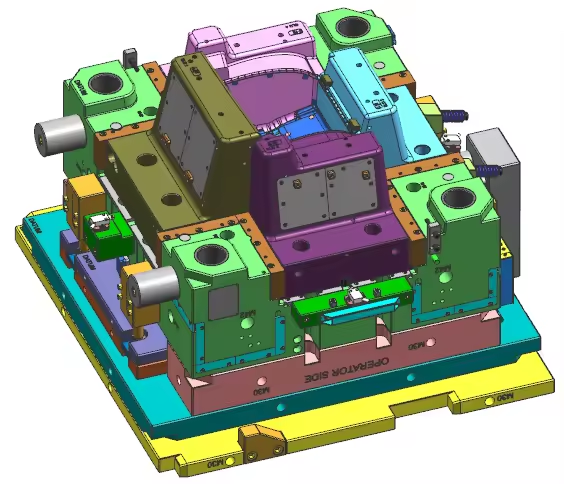

One type of prototyping tool in injection molding is the prototype mold. These tools are generally more lightweight and significantly less expensive than production molds because they are designed with small production runs in mind instead of mass production. Prototyping tools are primarily intended to confirm product design, evaluate functionality, and highlight any design issues before ramping up to full production.

Prototyping tools tend to have simpler designs, helping to speed fabrication and reduce costs. They are made of less expensive materials since these are meant for testing rather than surviving impact. They do have to conform to some specifications so that they can accurately simulate the features of the product being tested.

3. Prototyping Tools vs. Production Tools in Injection Molding

Before we discover one or the other, it is critical to figure out and consider the differences between prototyping tools and production tools to choose wisely as per the phases of the product development cycle. Here’s how they stack up against each other:

| Feature | Prototyping Tool | Production Tool |

| Purpose | Testing and design validation | Mass production and long-term use |

| Material | Typically lower-cost materials | High-quality, durable materials for high-volume production |

| Tool Design | Simpler, faster to manufacture | Complex, designed for high precision and longevity |

| Cost | Lower cost, more affordable | Higher cost due to complexity and material choice |

| Production Volume | Small-scale production (few hundred parts) | Large-scale production (thousands to millions of parts) |

| Turnaround Time | Fast turnaround for rapid prototyping | Longer turnaround time due to complexity and precision requirements |

Production tools are built for robustness and precision, creating high-quality parts at scale, while prototyping tools are built for speed and cost. Which one to use will depend on the stage of the project and the anticipated production volume.

4. When To Use A Prototyping Tool

Prototyping tools come in handy while developing products during the starting phase. They enable designers and engineers to:

- Confirm Product Fit and Function: Prototypes can be tested before dedicating the factory to more mass production to ensure the product meets all specifications.

- Validate Design Changes: If there are modifications in design, prototyping tools enable quick updates and iterations to validate changes.

- Test with Users: Prototypes allow companies to test their ideas with users to see how they hold up in practice, get feedback, and adapt and improve designs based on real-world use.

Prototyping tools are generally utilized whenever:

- You have a design concept to test with a physical model.

- It is still very much a work in progress, and full-scale production is premature.

- You have to functional test in a live, real-world environment.

In such instances, prototyping tools are useful, being more affordable, flexible, and capable of flagging issues before incurring the high costs of production tooling.

5. The Impact of Prototyping Injection Molding on Design

Prototyping injection molding has a significant impact on product design by enabling rapid iterations and testing of various features and functions. Here’s how:

- Design Improvements: Prototyping enables designers to easily adjust dimensions, proportions, and features based on test results. If a prototype reveals weaknesses, it can be quickly tweaked — saving time and money.

- Prototype Materials: In production parts, materials are often stressed more than in prototypes, so different material characteristics may be found in prototypes. Testing prototypes under various conditions (heat, pressure, or stress) helps determine the best material choices.

- Precision Testing: While prototyping tools aren’t as complex as production molds, they still provide insights into how parts will perform once produced at scale. Testing a prototype’s tolerance levels can ensure the final design meets functional specifications.

- Cost-Effective Design: Early design validation can prevent costly redesigns during the production phase.

Prototyping is a feedback loop that enables designers to improve products based on real-world data. It allows for rapid iterations and design testing, resulting in better products at lower costs.

6. Rapid Prototyping in Injection Molding FAQs

1. What is the typical lead time for rapid prototyping in injection molding?

Lead times range from 5–15 business days, depending on design complexity, material availability, and surface finish requirements. For urgent projects, expedited services (3–7 days) may be available with a 20–30% surcharge.

2. How does rapid prototyping in injection molding differ from traditional prototyping?

Rapid prototyping uses soft tooling (e.g., aluminum molds) and advanced techniques like 3D-printed inserts to produce functional prototypes in days, while traditional methods involve costly steel molds and weeks of lead time. This reduces upfront costs by 40–60%.

3. What materials can be used for rapid injection molding prototypes?

Common materials include:

- Plastics: ABS, PP, PC, Nylon, PEEK.

- Specialty resins: Flame-retardant, glass-filled, or FDA-compliant grades.

Note: High-temp materials (e.g., PEEK) may require longer cycle times.

4. How many prototype units can be produced with rapid tooling?

Aluminum molds typically support 50–500 units, ideal for functional testing or small-batch production. For higher volumes (>1,000 units), transition to steel molds is recommended.

5. What design limitations exist for rapid injection molding prototypes?

- Avoid undercuts unless sliding cores are added (increases cost).

- Wall thickness should stay between 1–4mm to prevent warping.

- Draft angles ≥1° are required for easy part ejection.

6. How do you ensure prototype accuracy compared to final production parts?

- Mold flow analysis to predict shrinkage/warping.

- Tolerance control: ±0.1mm for critical dimensions.

- Post-process inspections (CMM, 3D scanning) to validate specs.

7. Can rapid prototypes be used for functional testing (e.g., load-bearing, heat resistance)?

Yes. Prototypes made from engineering-grade resins (e.g., PC/ABS, PEEK) can undergo:

- Mechanical stress tests (up to 100 MPa).

- Thermal cycling (-40°C to 150°C).

- Chemical exposure trials.

8. What surface finishes are available for rapid prototypes?

Options include:

- SPI standards: Glossy (SPI-A1), textured (SPI-C1), or matte (SPI-D1).

- Custom finishes: EDM textures, laser etching, or post-polishing (Ra ≤0.4μm).

9. How much does rapid injection molding prototyping cost?

Costs start at 1,500–5,000 for tooling + $0.5–20/unit, depending on:

- Mold complexity (e.g., side actions, insert molding).

- Material type (standard vs. specialty resins).

- Surface finish requirements.

10. Can rapid prototyping tooling be reused for mass production?

Aluminum molds are ideal for prototypes but wear faster than steel. For mass production (>10k units), we recommend:

- Bridge tooling: Hybrid molds with steel cores for critical areas.

- Design adjustments: Optimize gate locations and cooling channels for high-volume runs.

7. Summary

Rapid prototyping in injection molding is crucial for creating high-quality, cost-efficient product designs. Prototyping tools help companies validate designs and identify potential issues before mass production. Unlike production molds, these tools are made from different materials, have simpler designs, cost less, and serve different purposes. Production tools are used for large-scale manufacturing, while prototyping tools enable quick design iterations and product testing at a fraction of the cost.

If you want to bring your product from concept to launch quickly, leveraging rapid prototyping in injection molding is the way to go. It accelerates design validation, enhances the final product, and is both cost-effective and low-risk.

8. About BFY Mold

BFY Mold specializes in plastic and metal injection molding and OEM manufacturing, with expertise in mold design and mechanical processing. We provide high-quality mold tools and reliable injection molding solutions tailored to each project. Our in-house factory and experienced team ensure timely, cost-effective manufacturing services.