Requirements for two-shot injection molding materials

Two-shot injection molding industry is developing rapidly, and the current market is hot. The two-shot injection molding process can make the product look more beautiful, and it is easy to change color without spraying. However, the price is expensive and the technical requirements are high. Matching materials for two-shot injection molding must meet two basic compatibility conditions: adhesive compatibility and process compatibility. In addition, the following requirements must be met:

(a) The injection unit is a single cylinder injection structure with the parallel and same direction, parallel and reverse direction, horizontal and vertical L-shape, and Y-shape.

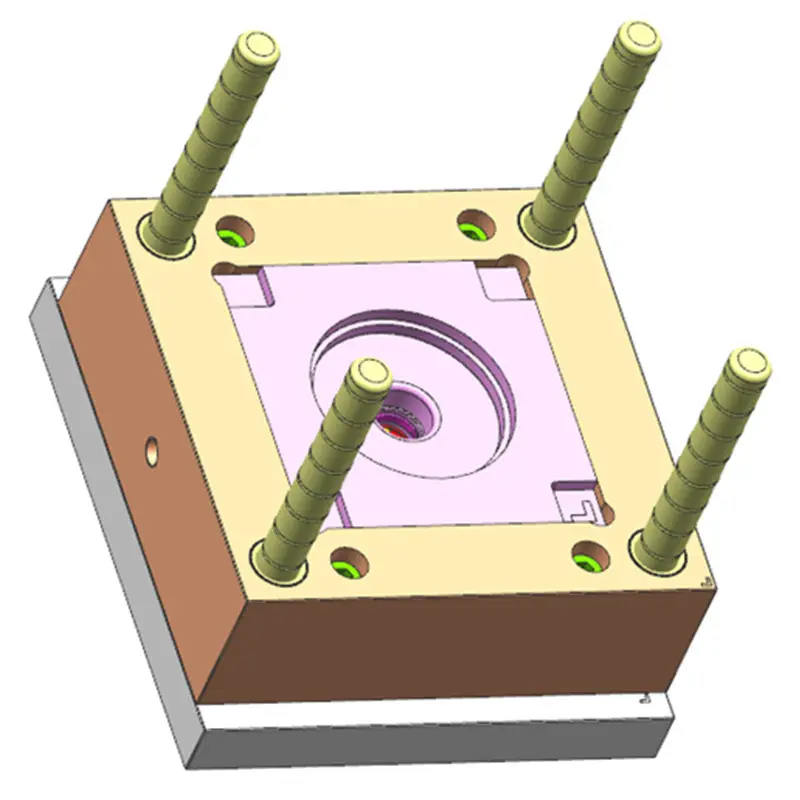

(b) clamping die, standard parts, vertical turntable, horizontal turntable, rotating shaft, manipulator rotating mechanism, etc.

(c) in addition to the standard hydraulic motor drive, there is an ESD(ElectricScrewDrive) electric feeding structure.

(d) Mixing special nozzles with patterns, waves, flow marks, gradients, and interlayers.

(e) The oil circuit adopts ACC storage, high-speed injection, and closed circuit design.

Two-shot injection molding for high responsiveness and repeatability and increased speed stability. Two raw materials or two colors can be formed at the same time, greatly reducing the process and manpower, and achieving cost savings. Parameters are set, and the system is tuned to very simple digital operations.

Pressure control during two-shot injection molding

Two-shot injection molding has two important processes: filling and pressure retention, so how should we control the injection pressure when forming two-shot injection molds?

a. Inject pressure

At present, the injection pressure of almost all injection molding machines is based on the pressure exerted on the plastic by the plunger or screw top (converted from oil pressure), and the role of injection pressure in injection molding is to overcome the flow resistance of the plastic from the barrel to the cavity, giving the melt filling rate and compacting the melt.

b. Plasticizing pressure

In the injection, the plasticizing pressure varies with the design of the screw, the requirements of the product quality, and the type of plastic, if these conditions and the screw speed are unchanged, increasing the plasticizing pressure will strengthen the shear, that is, it will increase the melt temperature, but it will reduce the plasticizing efficiency, increase the countercurrent and leakage, and increase the drive power.

In addition, increasing the plasticizing pressure can often make the melt temperature uniform, the color mixture uniform, and the gas discharged from the melt, under normal circumstances, under the premise of ensuring good product quality, the plasticizing pressure should be determined as low as possible, the specific value varies according to the variety of plastic two-shot mold used, but usually rarely more than 20kg/cm².