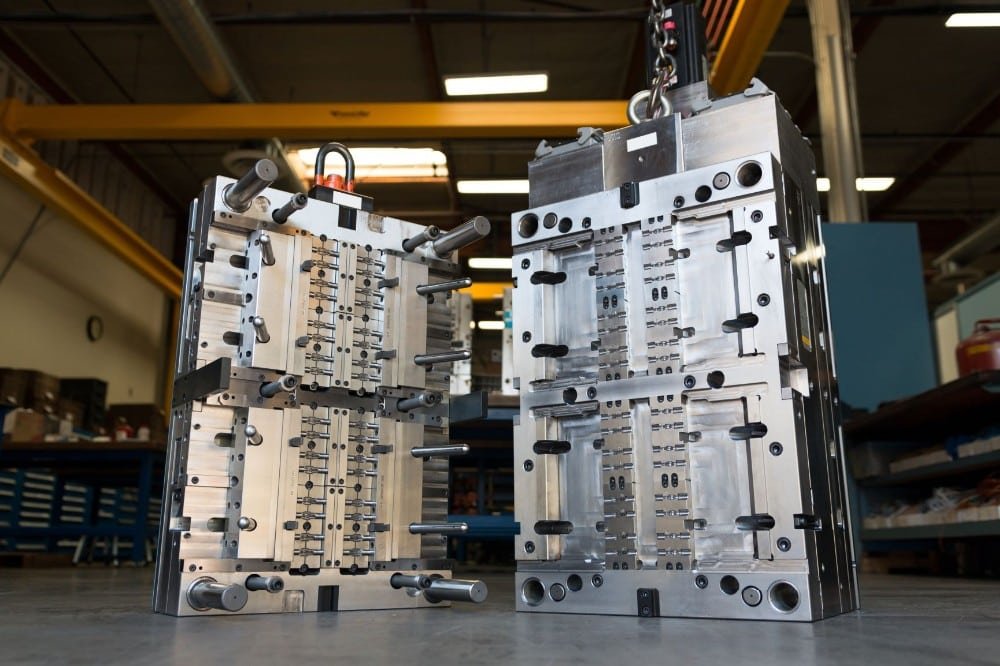

Single Cavity vs Multi Cavity Molds

In injection molding, choosing the right mold type is crucial to your project’s success. The decision between single-cavity and multi-cavity molds can significantly impact production efficiency, cost, and the quality of the final product. Now delves into the key differences between single-cavity and multi-cavity molds, exploring their structures, advantages, functions, and how to choose the right one for your specific needs.

What is the Single Cavity Mold?

A single cavity mold is designed to produce one part per injection cycle. This type of mold is often used in scenarios where precision is critical, or where the production volume does not justify the complexity and cost of a multi-cavity mold. Single cavity molds are simpler in design, with fewer moving parts, making them easier to manage and maintain.

One of the primary advantages of single cavity molds is their ability to produce high-quality, consistent parts. Since only one cavity is involved, variations or inconsistencies between parts are less likely. This is particularly important for industries where precision and quality control are paramount, such as medical or aerospace applications.

What is the Multi-Cavity Mold?

In contrast, a multi-cavity mold is designed to produce multiple identical parts in a single injection cycle. The number of cavities can vary widely, with some molds containing two, four, eight, or even more cavities. This design is ideal for high-volume production where the goal is to maximize output and minimize cycle time.

Multi-cavity molds are commonly used in industries where large quantities of parts are required in a short period, such as in consumer goods or automotive manufacturing. The ability to produce multiple parts simultaneously leads to significant cost savings on a per-part basis, as well as increased efficiency in the production process.

Structure Comparison: Single Cavity vs Multi Cavity Mold

The basic structure of both single-cavity and multi-cavity molds includes similar components: a mold base, cavity, core, cooling channels, and a runner system. However, the design complexity increases with multi-cavity molds.

- Single Cavity Mold Structure: The single cavity mold consists of one cavity and one core. The cavity forms the shape of the part, while the core is the part that shapes the interior surfaces. The cooling channels are strategically placed to ensure even cooling of the molded part, reducing the likelihood of defects. The runner system in a single cavity mold is simpler, as it only needs to deliver molten material to one cavity.

- Multi-Cavity Mold Structure: Multi-cavity molds, while based on the same principles, are more complex. Multiple cavities and cores are arranged within the same mold base, each requiring precise alignment to ensure uniform production. The runner system must be designed to deliver molten material evenly to each cavity, which can be challenging to achieve. Additionally, cooling channels must be carefully designed to ensure that all parts cool at the same rate, preventing variations in quality.

The complexity of multi-cavity molds also extends to the mold base, which must be robust enough to withstand the increased clamping force required to hold multiple cavities together during the injection process. This often necessitates the use of higher-grade materials and more precise machining, leading to higher initial costs compared to single cavity molds.

Advantages of Single Cavity Molds

- Precision and Quality: With only one cavity, the risk of variation between parts is minimized, ensuring consistent quality.

- Simpler Design: The straightforward design of single cavity molds makes them easier to manufacture, maintain, and troubleshoot.

- Lower Initial Cost: The simpler structure of single cavity molds typically results in lower tooling costs, making them a cost-effective option for low to medium production volumes.

- Faster Setup Times: With fewer components to align and manage, single cavity molds often require less setup time, leading to quicker turnaround for small batch productions.

Advantages of Multi-Cavity Molds

- Higher Production Efficiency: Multi-cavity molds can produce multiple parts in a single cycle, significantly increasing production output and reducing overall cycle time.

- Lower Cost per Part: While the initial cost of a multi-cavity mold is higher, the cost per part decreases as production volume increases, making it a cost-effective solution for large-scale production.

- Consistent Quality Across Multiple Parts: When properly designed and maintained, multi-cavity molds can produce parts with consistent quality across all cavities, ensuring uniformity in mass production.

- Optimized Use of Materials: Multi-cavity molds can lead to better material utilization, reducing waste and improving overall production efficiency.

Function of Single and Multi-Cavity Molds

The primary function of both single and multi-cavity molds is to shape molten material into a finished part. However, their specific functions and applications can vary based on production needs:

Single Cavity Molds:

Best suited for small production runs, prototype development, or situations where part precision and quality are critical. They are also ideal for larger parts that require a simpler mold design.

Multi Cavity Molds:

Ideal for high-volume production where efficiency and output are the primary concerns. Multi-cavity molds are commonly used in industries like automotive, consumer electronics, and packaging, where thousands or even millions of parts need to be produced quickly and consistently.

How to Choose Between Single and Multi-Cavity Molds

Choosing the right mold type depends on several key factors:

- Production Volume: If your project requires many parts, a multi-cavity mold may be the most cost-effective and efficient choice. A single cavity mold may be more appropriate for smaller runs or specialized parts.

- Part Complexity and Size: Complex or large parts may be better suited for single cavity molds, allowing for more precise control and quality assurance. Smaller, simpler parts can often be produced more efficiently with a multi-cavity mold.

- Budget: Consider both the initial tooling cost and the long-term production cost. While multi-cavity molds have a higher upfront cost, they can lead to significant savings in high-volume production. Conversely, single cavity molds may be more economical for lower-volume projects.

- Lead Time: If your project has a tight deadline, multi-cavity molds can help speed up production by producing multiple parts simultaneously. However, the longer lead time required to design and manufacture a multi-cavity mold may offset this advantage.

- Quality Requirements: If your project demands the highest level of quality and precision, a single cavity mold may be the better choice, as it allows for more meticulous control over the molding process.

10 Key FAQs for Optimal Supplier Selection

1. What are the main differences between single-cavity and multi-cavity molds?

Single-cavity molds produce one part per cycle, ideal for prototypes or low-volume orders. Multi-cavity molds produce 2–128+ identical parts per cycle, optimized for mass production.

2. How do costs compare between single and multi-cavity molds?

- Single cavity molds: 5,000–20,000 (simpler tooling).

- Multi cavity molds: 30,000–100,000+ (complex designs, hardened steel).

Cost per part drops by 40–70% with multi-cavity molds for high-volume orders.

3. When should I choose a single cavity mold?

Choose a single cavity for:

- Prototyping: Test designs before mass production.

- Low-volume orders: 50–1,000 units.

- Complex geometries: Focus on precision for intricate parts.

4. What industries benefit most from multi cavity molds?

- Packaging: High-volume lids, caps (e.g., 64-cavity systems).

- Electronics: Small connectors, housings.

- Medical: Disposable syringes, IV components.

5. How does mold material choice impact single vs multi cavity performance?

- Single cavity: Aluminum (lower cost, faster turnaround).

- Multi cavity: Hardened steel (H13, NAK80) for durability (500k+ cycles).

6. What are the quality risks with multi cavity molds?

- Cavity imbalance: Uneven filling causes dimensional variation (±0.1mm).

- Wear consistency: High-volume runs risk uneven tooling degradation.

Mitigate with mold flow analysis and SPC monitoring.

7. How do cycle times differ between single and multi cavity molds?

- Single cavity: 30–60 seconds/cycle (varies with part size).

- Multi cavity: 10–30 seconds/cycle (concurrent part production).

8. Can multi cavity molds handle different part designs in one tool?

Yes. Family molds produce multiple unique parts in one cycle but increase complexity and cost by 20–40%.

9. What certifications should suppliers have for multi cavity molds?

- ISO 9001: Quality management.

- IATF 16949: For automotive components.

- Mold flow analysis reports: Validate cavity balancing.

10. How do I evaluate a supplier’s expertise in multi cavity mold production?

- Portfolio: Case studies for molds with 16+ cavities.

- Precision guarantees: ±0.05mm tolerances.

- Maintenance support: Post-production tooling inspections.

Conclusion

Deciding between single-cavity and multi-cavity molds involves a careful assessment of your production needs, budget, timeline, and quality requirements. Both types of molds have their unique advantages, and the right choice depends on the specific demands of your project.

At BFY Mold, we specialize in providing tailored injection molding solutions to meet your unique production requirements. Whether you need a single-cavity mold for precision parts or a multi-cavity mold for high-volume production, our expert team can guide you through the process. With a focus on injection molding and mold manufacturing, mass production, on-demand production, CNC machining, and mirror spark, our in-house factory ensures high-quality results customized to your specifications. Let us help you achieve your production goals with the right molding solution.