Introduction

In the dynamic manufacturing world, where precision and efficiency are paramount, injection molding stands out as a game-changing technology. This versatile and highly efficient process has revolutionized the production of countless products we use every day. Let’s learn that we delve into the myriad benefits of injection molding, exploring why it has become a cornerstone of modern manufacturing and how it can transform your production processes.

The Advantages of Injection Molding

1. High Efficiency and Speed

Injection molding is renowned for its ability to produce parts at high speeds with remarkable efficiency. Once the initial mold is created, the production process is speedy compared to other manufacturing methods. This speed is particularly beneficial for high-volume production runs, enabling companies to meet market demands promptly and cost-effectively.

2. Consistency and Repeatability

One of the standout features of injection molding is its unparalleled consistency. Each part produced is virtually identical to the last, ensuring uniformity and high quality across all units. This repeatability is essential for industries where precision and reliability are critical, such as automotive, medical, and consumer electronics.

3. Complex Geometries and Intricate Designs

Injection molding excels at producing complex geometries and intricate designs that would be challenging or impossible with other manufacturing techniques. The ability to create detailed and intricate parts with tight tolerances makes it an ideal choice for innovative product designs. This flexibility allows manufacturers to push the boundaries of creativity and functionality.

4. Material Versatility

The injection molding process is compatible with a wide range of materials, including various types of plastics, elastomers, and even metals. This versatility allows manufacturers to select the best material for their specific application, balancing factors such as strength, flexibility, and cost. The choice of material can significantly impact the performance and durability of the final product.

5. Cost-Effectiveness

While the initial investment in mold creation can be significant, the long-term cost benefits of injection molding are substantial. The high production speed and low labor costs associated with this process lead to significant cost savings over time. Additionally, the minimal waste generated during production contributes to its cost-effectiveness and environmental sustainability.

6. Reduced Waste and Environmental Impact

Injection molding is a highly efficient process with minimal material waste. Excess material from each cycle can often be recycled and reused, further reducing waste and promoting sustainability. This eco-friendly aspect of injection molding aligns with the growing emphasis on environmentally responsible manufacturing practices.

7. Automation and Reduced Labor Costs

The injection molding process is highly automated, requiring minimal human intervention. Advanced machinery and robotics handle most of the production tasks, leading to lower labor costs and reduced chances of human error. This automation also ensures consistent quality and higher production rates, making it an attractive option for large-scale manufacturing.

8. Scalability

Injection molding offers exceptional scalability, making it suitable for both small and large production runs. Whether you need a few hundred parts or millions, the process can be adjusted to meet your specific production requirements. This scalability is particularly advantageous for businesses looking to grow and adapt to changing market demands.

How BFY Mold Can Help You Harness the Power of Injection Molding

At BFY Mold, we specialize in leveraging the benefits of injection molding to provide top-tier manufacturing solutions. Our state-of-the-art facility is equipped with cutting-edge technology, enabling us to deliver high-quality, cost-effective, and efficient production services. Whether you require mass production or on-demand manufacturing, our team of experts is dedicated to meeting your unique needs.

Our comprehensive range of services includes:

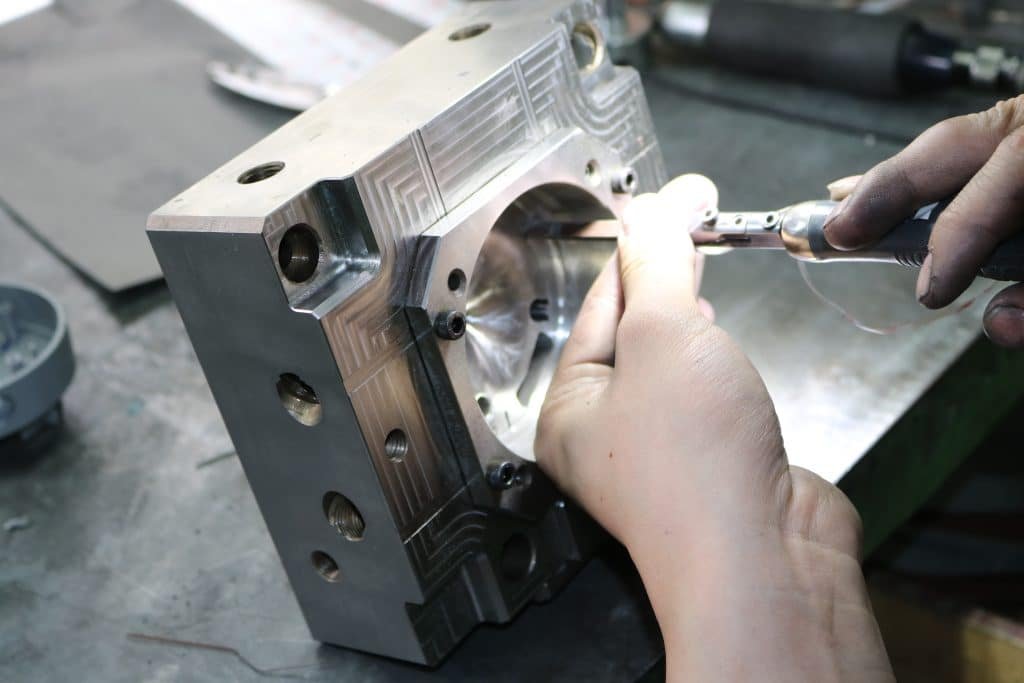

- Injection Molding and Mold Manufacturing: We design and produce custom molds to ensure precision and consistency in every part.

- Mass Production and On-Demand Production: Our flexible production capabilities cater to both large-scale orders and smaller, specialized runs.

- CNC Machining and Mirror Spark: We offer advanced CNC machining and mirror spark services for high-precision parts and intricate designs.

With our factory and a commitment to excellence, BFY Mold is your trusted partner in bringing innovative ideas to life. Contact us today to discover how our injection molding expertise can transform your manufacturing processes and help you stay ahead in a competitive market.

Summary

Injection molding is a powerful manufacturing technique that offers numerous advantages, from high efficiency and consistency to the ability to produce complex geometries. By partnering with a trusted provider like BFY Mold, you can unlock the full potential of this technology and achieve unparalleled precision and quality in your products. Embrace the future of manufacturing with injection molding and experience the benefits firsthand.