Introduction:

In the world of plastic injection molding, the demand for lightweight, durable, and cost-effective products has led to the rise of thin wall molding. This innovative technique allows manufacturers to produce parts with walls as thin as 0.5 mm, which is significantly thinner than traditional injection molding methods. Thin wall molding is widely used in the production of consumer electronics, medical devices, and packaging solutions. This comprehensive guide will delve into what it is, why it’s chosen over traditional methods, the materials used, its advantages and functions, and how to make the right choice for your project.

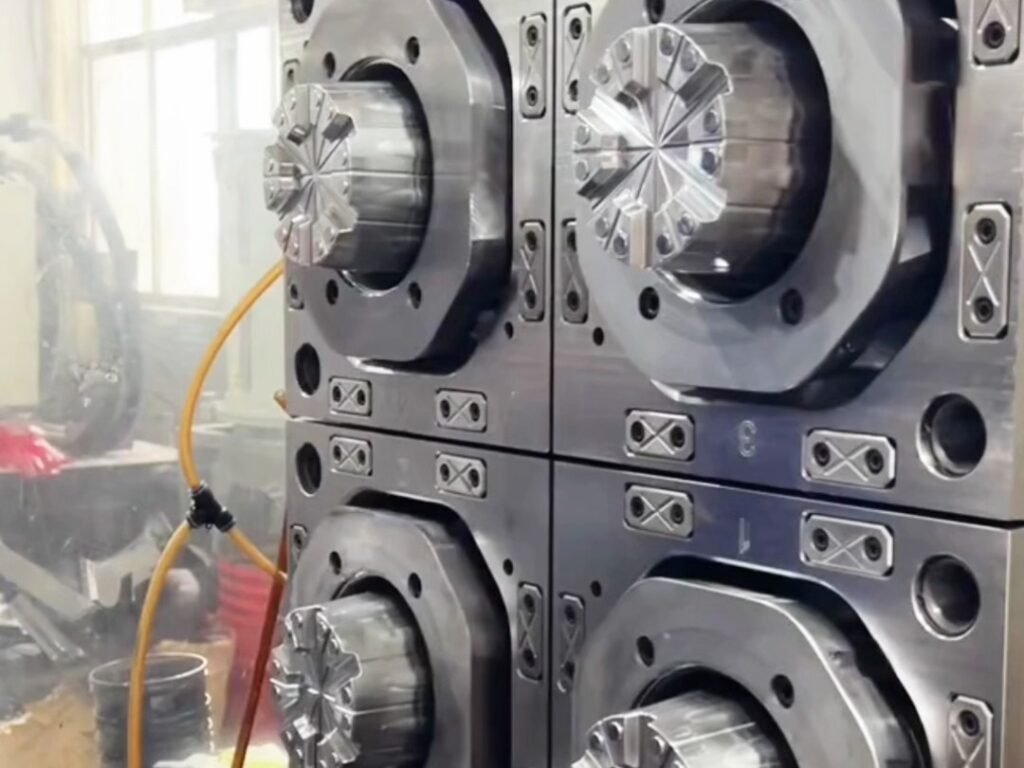

What Is Thin Wall Mold?

Thin wall molding is a specialized injection molding process designed to produce parts with walls much thinner than those made using conventional methods. The term “thin wall” typically refers to a wall thickness of less than 1 mm. This process requires precise machinery and expertise to ensure that the molten plastic flows quickly and evenly into the mold before it cools and solidifies.

Why Choose Thin Wall Molds?

Thin wall molds are chosen for several compelling reasons:

- Material Savings: Thinner walls mean less material is used, reducing costs and making the process more environmentally friendly.

- Faster Cycle Times: The reduced wall thickness allows for quicker cooling and ejection of parts, leading to higher production rates.

- Improved Strength-to-Weight Ratio: Thin wall parts are surprisingly strong and durable, making them ideal for applications where weight is a critical factor.

- Enhanced Aesthetics: Thin wall molding can produce parts with sleek, modern lines that are perfect for consumer electronics and other design-conscious products.

Which Materials Can Make Thin-Walled Molds?

The materials used for the mold must have excellent flow characteristics to fill the mold cavity quickly. Common materials include:

- Polypropylene (PP): Known for its excellent flow properties and high strength-to-weight ratio.

- High-Density Polyethylene (HDPE): Offers good chemical resistance and stiffness.

- Polyethylene Terephthalate (PET): Ideal for clear, strong, and lightweight parts.

- Acrylonitrile Butadiene Styrene (ABS): Provides good impact resistance and is easy to paint and glue.

Advantages and Functions

Thin wall molding offers numerous advantages and serves various functions:

Advantages:

- Cost-Effective: Reduced material usage and faster cycle times lower production costs.

- Lightweight: Thin wall parts are ideal for applications where weight reduction is essential.

- High Production Rates: Faster cycle times enable higher output, perfect for mass production.

- Versatility: Suitable for a wide range of applications, from packaging to automotive parts.

Functions:

- Protective Packaging: Thin wall molding is widely used for producing packaging that is both lightweight and robust.

- Consumer Electronics: The process is ideal for creating sleek and durable components for electronic devices.

- Medical Devices: The ability to produce thin, strong parts makes it suitable for medical applications.

How to Choose?

When selecting the mold manufacturers, consider the following factors:

- Material Compatibility: Ensure the mold material is compatible with the plastic you intend to use.

- Mold Complexity: More complex designs may require advanced mold-making techniques.

- Production Volume: High-volume production may justify the investment in a more expensive, high-performance mold.

- Wall Thickness: The desired wall thickness will dictate the type of mold and machinery required.

Comparison Sections

| Comparison Factor | Thin Wall Mold | Traditional Mold |

| Wall Thickness | < 1 mm | > 1 mm |

| Material Usage | Less | More |

| Cycle Time | Faster | Slower |

| Production Rate | Higher | Lower |

| Strength-to-Weight | Higher | Lower |

| Aesthetics | Sleek | Bulkier |

Top 10 FAQs for Supplier Selection

1. What defines a thin wall mold, and how does it differ from standard molds?

Thin wall molds are designed for parts with wall thickness ≤1mm (vs. 2–4mm for standard molds). They require high-speed injection (cycle times <10 seconds) and precision cooling to prevent warping or sink marks.

2. What industries commonly use thin wall molding?

- Packaging: Food containers, lids (e.g., 0.3mm yogurt cups).

- Electronics: Smartphone casings, micro connectors.

- Medical: Disposable syringes and blister packs.

3. What materials are best suited for thin wall molding?

- Polypropylene (PP): Low viscosity, ideal for high-speed filling.

- PET: For transparent, rigid packaging (e.g., 0.25mm trays).

- LCP (Liquid Crystal Polymer): High-flow grades for microelectronic components.

4. How much does the mold cost compared to traditional molds?

- Aluminum thin wall molds: 15,000–50,000 (prototyping/low-volume).

- Steel molds: 50,000–200,000+ (mass production). Costs rise with multi-cavity designs (e.g., 64-cavity systems for packaging).

5. What injection molding machines are optimal for thin wall applications?

High-speed machines with:

- Clamping force: 100–300 tons (for small parts).

- Injection speed: ≥500 mm/sec.

- Hybrid/electric drives: For energy efficiency (±5% shot consistency).

6. How do you prevent defects like short shots or warping in thin wall molding?

- Mold design: Conformal cooling channels (±1°C uniformity).

- Process control: Melt temp ±2°C, hold pressure ≥1,500 psi.

- Material drying: Moisture content <0.02% for hygroscopic resins.

7. What certifications should suppliers have?

- ISO 9001: Quality management.

- ISO 13485: For medical device molds.

- SPI-A1: Surface finish certification for glossy packaging.

8. How does part design impact mold costs?

- Rib-to-wall ratio: ≤50% to avoid sink marks.

- Draft angles: ≥0.5° for ejection.

- Gate design: Hot runners (needle gates) reduce cycle time by 20–30%.

9. Can recycled materials be used in thin wall molding?

Yes, but:

- Post-consumer PP: Requires MFI ≥30g/10min for flowability.

- Contamination limits: ≤0.1% for food-grade applications.

10. How do I evaluate a supplier’s expertise in thin wall molding?

- Portfolio: Case studies for parts <0.5mm.

- Tooling validation: Mold flow analysis reports.

- Cycle time guarantees: e.g., ≤8 seconds for 0.3mm walls.

Conclusion:

Thin wall molding is a cutting-edge technology that offers numerous benefits over traditional molding methods. Its ability to produce lightweight, durable, and cost-effective parts makes it an excellent choice for a wide range of applications. When choosing a thin wall mold, consider the material compatibility, mold complexity, production volume, and desired wall thickness. With the right mold and expertise, thin wall molding can significantly enhance your product’s performance and appeal.

About BFY Mold:

At BFY Mold, we are dedicated to providing top-notch injection molding and mold manufacturing services. With our state-of-the-art factory, we specialize in mass production, on-demand production, CNC machining, and mirror spark processes. Our commitment to quality and innovation ensures that our clients receive the best possible solutions for their plastic molding needs. Contact us today to learn more about how we can help bring your product ideas to life.