In the wave of modern industry, PVC plastic molds with their unique advantages have become an important force to promote industrial development. It has won the favor of many enterprises with its excellent performance characteristics and wide application fields. Today, let’s explore the magic of PVC plastic mold and see how it brings revolutionary change to all walks of life.

PVC Plastic Molds in Home Appliances: Durability & Cost Efficiency

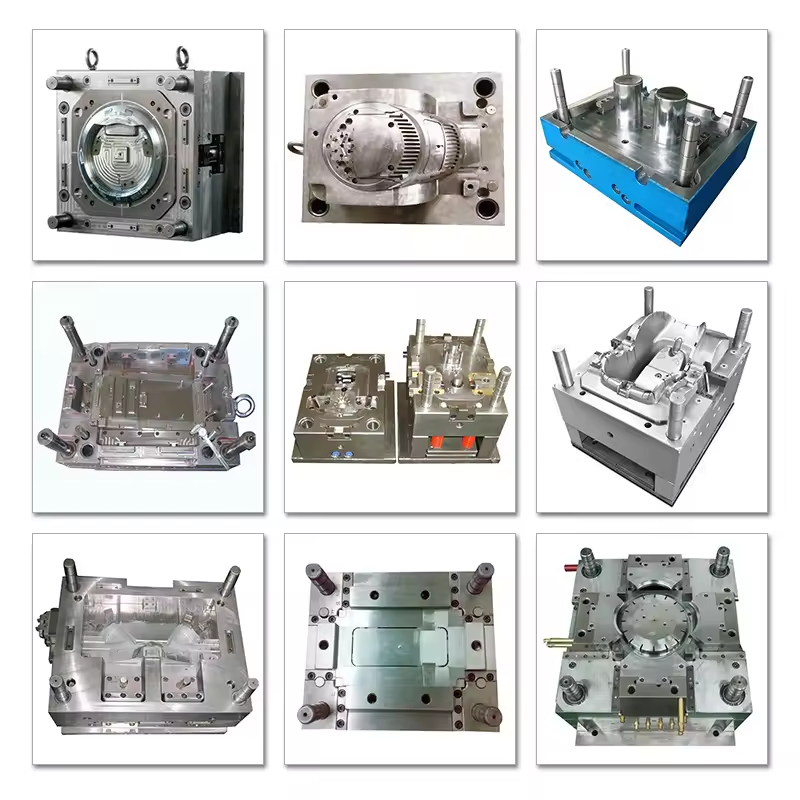

The application of PVC plastic mold in the home appliance industry can be described as pivotal. Whether it is a TV, refrigerator, or washing machine, these home appliances’ shells and internal structures are inseparable from the precise shaping of PVC plastic molds. It can ensure that the product looks beautiful, the structure is solid, and provides consumers with an excellent user experience. At the same time, due to its excellent corrosion and wear resistance, PVC plastic molds can resist various environmental challenges that may be encountered while using household appliances, ensuring the product’s long-term durability.

Automotive Manufacturing: High-Performance PVC Mold Solutions

PVC plastic molds also play a vital role in automotive manufacturing. They need to accurately form the body, interior parts, and car parts. Their high precision and stability ensure the quality and performance of automotive products. The lightweight characteristics of PVC plastic molds are also in line with the development trend of automotive lightweight, which helps to reduce vehicle fuel consumption and emissions and achieve green travel.

Medical, Toy & Packaging Sectors: Versatile PVC Mold Adaptability

In addition, it is also widely used in toys, packaging, medical equipment, and other industries. It can create different shapes and colorful toy products to meet children’s imagination and creativity; In the packaging industry, PVC plastic molds can quickly and efficiently produce a variety of packaging materials, improving the added value of products and market competitiveness; In the medical device industry, its hygiene and safety have been widely recognized, providing strong support for the development of the medical industry.

Advantages of PVC Molds: Chemical Resistance & Design Flexibility

The reason why PVC plastic molds can be widely used in many industries is inseparable from its excellent performance characteristics. It has the advantages of good corrosion resistance, wear resistance, temperature stability, and lightweight and easy handling. These advantages enable PVC plastic molds to maintain stable performance in a variety of harsh environments, extend service life, and improve production efficiency.