Introduction

Thermoplastic rubber (TPR materials) bridges the gap between rigid plastics and elastic rubbers, offering unmatched flexibility, durability, and recyclability. Widely used in automotive, consumer goods, and medical industries, TPR plastic materials outperform traditional elastomers like TPE, PVC, and silicone in cost, processing speed, and sustainability. This guide dives into TPR’s properties, comparative advantages, and innovative applications, empowering businesses to make informed material choices.

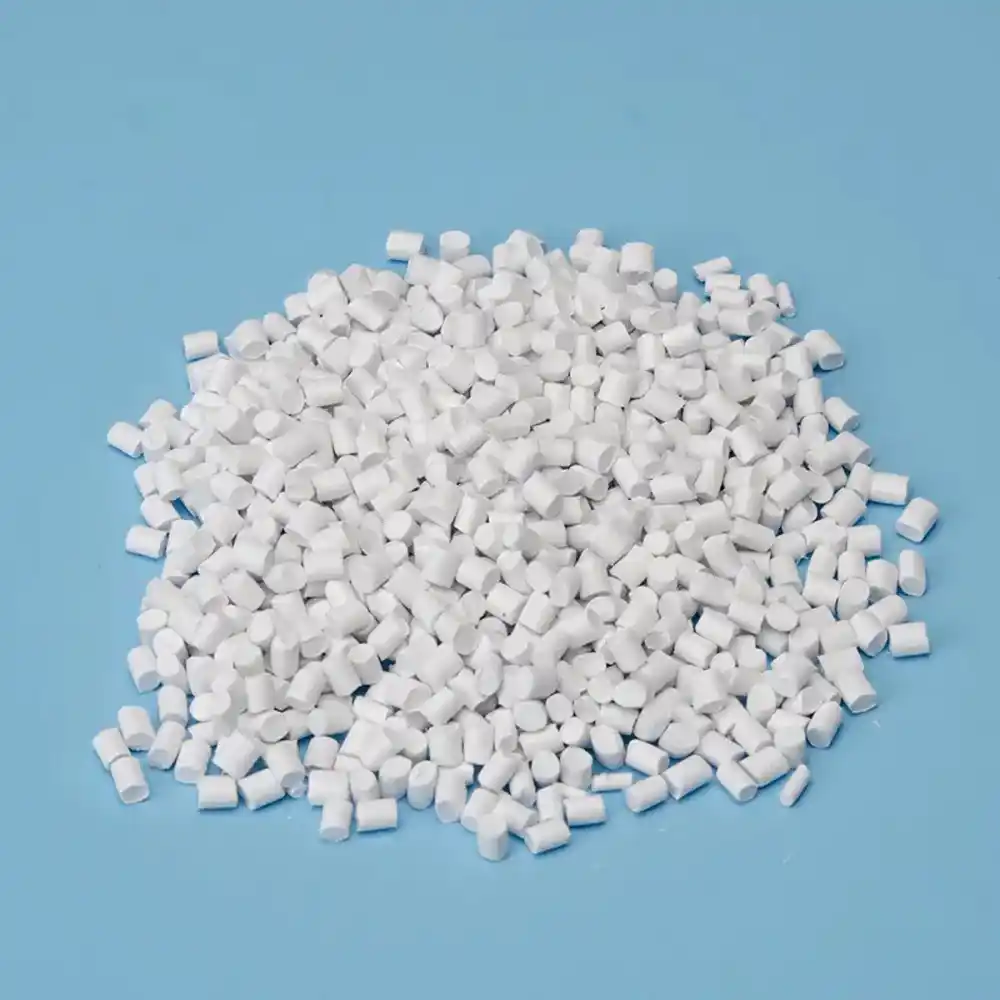

1. What is TPR Material?

TPR (thermoplastic elastomer) is a rubber and polypropylene (PP) or polyethylene (PE) mix, which adds the resilience of vulcanized rubber to the moldability. Some main features are as follows:

- Shore Hardness: 30A–90A (can be adjusted by modifying the polymer mix).

- Temperature Resistance: -40°C to 120°C.

- Recyclability: The performance of this material is, therefore, entirely sustainable and can be very well maintained in a closed-cycle system for future use.

Applications:

- Automotive seals, shoe soles, medical tubing (e.g., catheters), and soft-grip tool handles.

2. TPR vs. TPE: Flexibility vs. Cost Efficiency

2.1 Mechanical Properties Comparison

| Property | TPR Materials | TPE Materials | Advantage |

| Tensile Strength | 8–15 MPa | 10–25 MPa | TPE |

| Elongation at Break | 300–600% | 200–800% | TPE (Higher Elasticity) |

| Cost (USD/kg) | 2.5–4.0 | 3.0–6.0 | TPR |

| Processing Temperature | 180–220°C | 160–200°C | TPR (Wider Compatibility) |

| Recyclability | 100% Recyclable | Requires Multi-Layer Separation | TPR |

Source: Journal of Polymer Engineering (2024).

2.2 Best Use Cases

- TPR: High-volume automotive parts (e.g., weatherstripping).

- TPE: Overmolding electronics (e.g., smartphone cases).

3. TPR vs. PVC: Safety and Sustainability

| Property | TPR Materials | PVC Materials | Advantage |

| Chemical Composition | Chlorine-Free, Phthalate-Free | Contains Chlorine/Plasticizers | TPR |

| Heat Resistance | Up to 120°C | Up to 80°C | TPR |

| Medical Compliance | USP Class VI Certified | Limited to Non-Implant Use | TPR |

| Recycling Difficulty | Easy (Single Material) | Complex (Plasticizer Removal) | TPR |

| Typical Cost | 2.5–4.0/kg | 1.5–3.0/kg | PVC |

3.1 Environmental Impact

- TPR Plastic Materials: Phthalate-free, REACH-compliant.

- PVC: Contains chlorine and releases dioxins when incinerated.

3.2 Performance in Medical Applications

- TPR: USP Class VI-certified for implants.

- PVC: Limited to non-implant devices due to plasticizer leaching.

Case Study: MediFlex Solutions reduced hospital waste by 30%, switching from PVC to TPR IV tubes.

4. TPR vs. Silicone: Cost and Processing Speed

4.1 Cost Breakdown

| Property | TPR Materials | Silicone | Advantage |

| Cost (USD/kg) | 2.5–4.0 | 5.0–15.0 | TPR |

| Cycle Time | 20–40 seconds | 60–180 seconds | TPR |

| Temperature Range | -40°C to 120°C | -60°C to 230°C | Silicone (High Temp) |

| Hardness (Shore A) | 30A–90A | 20A–80A | Silicone (Softer) |

| Tooling Cost | Low (Aluminum Molds) | High (Steel Molds for HTV) | TPR |

4.2 High-Temperature Performance

- Silicone: Stable up to 230°C (HTV silicone).

- TPR: Limited to 120°C; ideal for consumer goods.

Trade-Off: Use silicone for aerospace and TPR for mass-produced goods.

5. Processing TPR Plastic Materials

5.1 Injection Molding Best Practices

- Melt Temperature: 180–220°C.

- Cooling Rate: Slow cooling to prevent warping.

- Mold Design: Polished surfaces to enhance gloss.

5.2 Extrusion and Blow Molding

- Extrusion: Ideal for seals and tubing (tolerance ±0.1mm).

- Blow Molding: Hollow products like squeezable bottles.

Tip: Add 1–3% lubricants (e.g., stearic acid) to reduce friction.

6. Eco-Friendly Advantages of TPR

- Recycling Rate: 95% regrind reuse in closed-loop systems.

- Carbon Footprint: 40% lower than silicone (per kg production).

- Biodegradable Blends: BASF’s ecoTPR® (30% plant-based content).

7. FAQs: Answering Key Industry Questions

1. Is TPR safe for baby products?

Yes, phthalate-free TPR complies with FDA 21 CFR 177.2600 for toys and pacifiers.

2. Can TPR replace latex in medical gloves?

Yes, TPR offers similar elasticity without allergy risks (e.g., SafeTouch MedGloves).

3. How does TPR handle UV exposure?

UV-stabilized TPR (e.g., Teknor Apex’s Elexar®) resists yellowing for 5+ years outdoors.

4. What’s the minimum order quantity (MOQ) for TPR?

Typically 500–1,000 kg, depending on compound customization.

5. Is TPR compatible with food-grade applications?

Yes, NSF-51-certified TPR is used in food packaging and kitchen utensils.

8. Future Trends in TPR Materials

- Self-Healing TPR: Microcapsule technology for automotive seals (Toyota’s 2025 prototype).

- Conductive TPR: Carbon nanotube-infused TPR for wearable electronics.

- 3D Printing Filaments: TPR-PLA blends for flexible prosthetics.

Conclusion

TPR materials dominate industries demanding elasticity, cost efficiency, and sustainability. By outperforming TPE in affordability, PVC in safety, and silicone in processing speed, TPR plastic materials are redefining modern manufacturing. Partner with suppliers offering customizable compounds to unlock their full potential.

Need a TPR Plastic Sample?

Contact BFY Mold for free material testing and technical support.