PET plastic molecular structure is highly symmetrical, and has a certain ability to crystallize orientation, so it has a high film formation and quality. PET plastics have good optical properties and weather resistance, and amorphous PET plastics have good optical transparency.

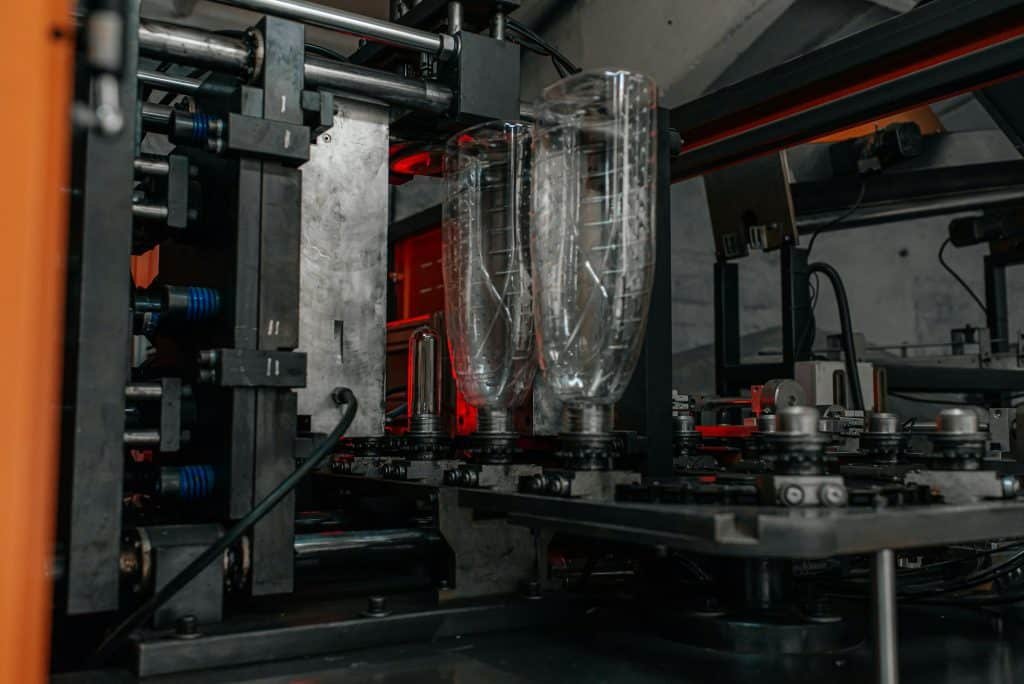

In addition, PET plastic has excellent abrasion resistance, dimensional stability, and electrical insulation. PET bottles have been widely used because of their high strength, good transparency, non-toxic, impermeable, lightweight, and high production efficiency.

PBT and PET molecular chain structure is similar, most of the properties are the same, but the main molecular chain from two methylene groups into four. Therefore, the molecules are more flexible and the processing properties are better.

PET is a milky white or light yellow highly crystalline polymer with a smooth and glossy surface. Creep resistance, fatigue resistance, good friction resistance, small wear, and high hardness, with the greatest toughness of thermoplastics; Good electrical insulation performance, little affected by temperature, but poor corona resistance. Non-toxic, weather resistant, chemical resistant, good stability, high moisture absorption, drying before forming is a must. Resistant to weak acids and organic solvents, but not heat resistant to water immersion, not alkali.

PET resin has a high glass transition temperature, slow crystallization rate, long molding cycle, long molding cycle, large molding shrinkage, poor dimensional stability, brittle crystallization molding, and low heat resistance.

Through the improvement of nucleating agents crystallizing agents and glass fiber reinforcement, PET has the following characteristics in addition to the properties of PBT:

Good Stability

The thermal deformation temperature and long-term service temperature are the highest in thermoplastic general engineering plastics.

Strong Heat Resistance

Because of the high heat resistance, the enhanced PET is impregnated for 10s in the solder bath at 250℃, almost without deformation or discoloration, which is especially suitable for the preparation of electronic and electrical parts of tin welding;

High surface hardness

The bending strength is 200MPa, the elastic modulus is 4000MPa, and the creep resistance and fatigue are also very good. The surface hardness is high, and the mechanical properties are similar to thermosetting plastics.

High-Cost performance

The price of ethylene glycol used to produce PET is almost half that of butanediol used to produce PBT. Therefore, PET resin and reinforced PET are the lowest price in engineering plastics, and have a high cost performance.

Waterproof material for adhesion

PET resin after curing is an elastomer with excellent waterproof, shock-proof adhesive, and resistance to high and low temperatures, so it is specially used for bonding engineering plastics.