Introduction

In low-volume manufacturing (1–10,000 units), choosing the right mold material is critical to balancing cost, speed, and quality. While steel molds dominate high-volume industries, aluminum molds are increasingly favored for prototypes and small batches.

BFY Mold’s analysis, backed by 50+ client projects, reveals how aluminum molds deliver 30–50% cost savings, 60% faster turnaround, and unmatched adaptability for iterative designs. Here’s why they outperform steel in low-volume scenarios.

1. Aluminum vs. Steel: Key Property Comparison

| Factor | Aluminum Molds | Steel Molds |

| Tooling Cost | 8,000–15,000 | 25,000–60,000 |

| Machining Time | 2–3 weeks | 6–12 weeks |

| Thermal Conductivity | 130–150 W/m·K | 15–50 W/m·K |

| Tool Life | 10,000–100,000 shots | 500,000–1M+ shots |

| Modification Cost | Low (soft material) | High (hardened steel) |

2. 4 Reasons Aluminum Dominates Low-Volume Production

① Faster Time-to-Market

- Rapid Machining: Aluminum’s softness allows CNC milling at 3x steel’s speed.

- Case: A consumer electronics customer used aluminum molds to complete a smart home shell trial production within 18 days, reducing the delivery cycle by 70% compared to steel molds.

② Lower Upfront Costs

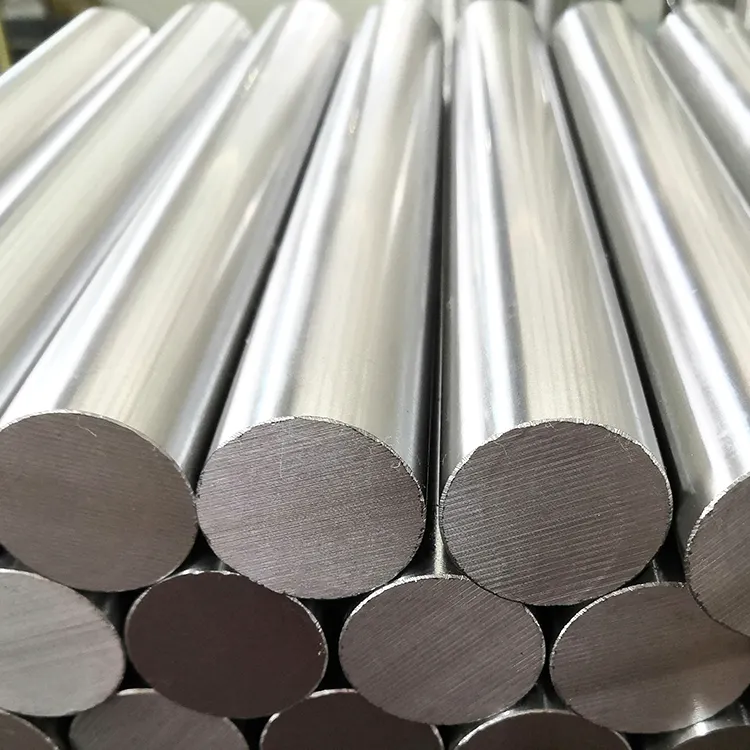

- Material Savings: 7075-T6 aluminum costs ~30/kg. P20steel’s 30/kg. P20 steel’s 5/kg (but steel requires 5x more material per mold).

- Hidden Savings: Eliminates post-machining hardening (steel molds need HRC 48–52 heat treatment).

③ Superior Cooling Efficiency

- Aluminum’s high thermal conductivity reduces cycle times by 15–25%:

- An auto parts customer produces PA66 sensor mounts with a cooling time of just 12 seconds for aluminum molds (16 seconds for steel molds), saving 1,200 hours per year for 5,000 units.

④ Design Flexibility

- Easy to modify for engineering changes (e.g., wall thickness adjustments, gate repositioning).

- Case in point: A medical startup iterated on version 3 of the design, and the aluminum mold modification cost totaled $2,100, only 10% of the steel mold.

3. When Steel Still Matters: Limitations of Aluminum

Aluminum isn’t a one-size-fits-all solution. Steel prevails in:

- High-Abrasion Scenarios: Glass-filled polymers (e.g., GF-Nylon) wear aluminum rapidly.

- Ultra-High Volumes: >50,000 shots require steel’s durability.

- Micro Features: Steel handles <0.2mm fine textures better.

4. Cost-Benefit Analysis: Aluminum’s ROI for 5,000 Units

| Expense | Aluminum Mold | Steel Mold |

| Tooling Cost | $12,000 | $40,000 |

| Per-Unit Cost* | $1.80 | $1.50 |

| Total Cost | (12,000+(5,000×1.80) = $21,000 | (40,000+(5,000×1.50) = $47,500 |

| Savings with Aluminum | $26,500 (55% lower) | / |

*Assume that the material is ABS, including machine time, labor, and energy consumption.

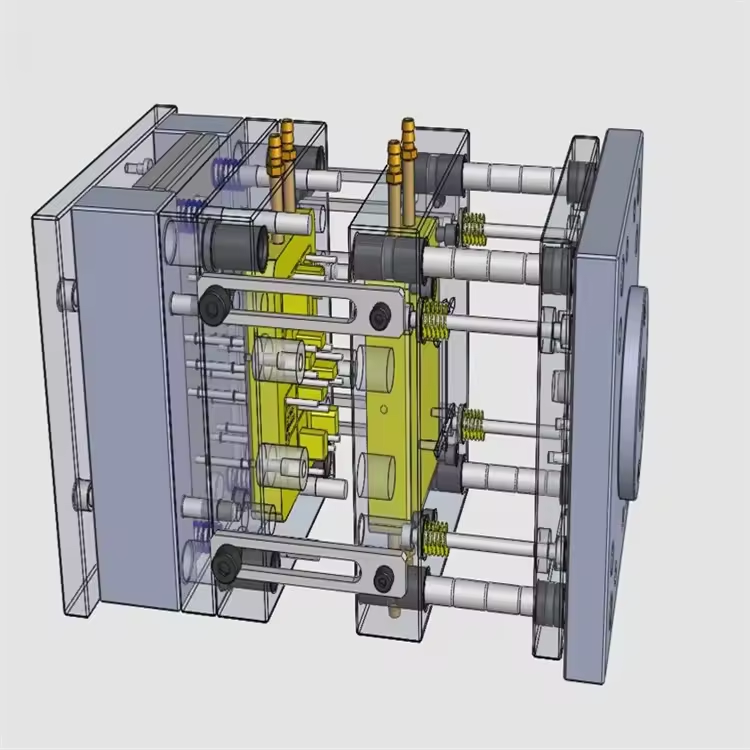

5. BFY Mold’s Aluminum Tooling Innovations

- Hybrid Molds: Steel inserts are embedded in key areas (e.g., gate, parting surface), and the life span is increased to 50,000+ shots.

- 3D-Printed Conformal Cooling: The aluminum mold is integrated with the shape water, increasing the cooling efficiency by 30%.

- AI-Driven Wear Monitoring: Real-time tracking of cavity wear, early warning replacement window, avoid unexpected downtime.

Customer Case:

A UAV manufacturer uses the BFY Mold aluminum + steel insert program to produce 10,000 carbon fiber reinforced PP parts, reducing mold costs by 42% and maintaining a 98% yield.

6. How to Decide on mold selection

a: Expected production?

- <10,000 pieces → Aluminum mold;>50,000 pieces →Steel molds.

b: Does the material contain abrasive filler?

- Glass fiber/carbon fiber >20% → Preferably steel mold or aluminum mold + steel inserts.

c. Is the design stable?

- Need to be modified several times → Aluminum mold flexibility and low-cost modification advantages.

Top 10 FAQs About Aluminum Molds

1. What are the key advantages of aluminum molds compared to steel molds?

Aluminum molds offer 30–50% lower costs, 2–4x faster lead times (3–6 weeks vs. 12+ weeks for steel), and lighter weight for easier handling. They are ideal for prototyping, low-volume production (50–10,000 units), and parts requiring rapid design iterations.

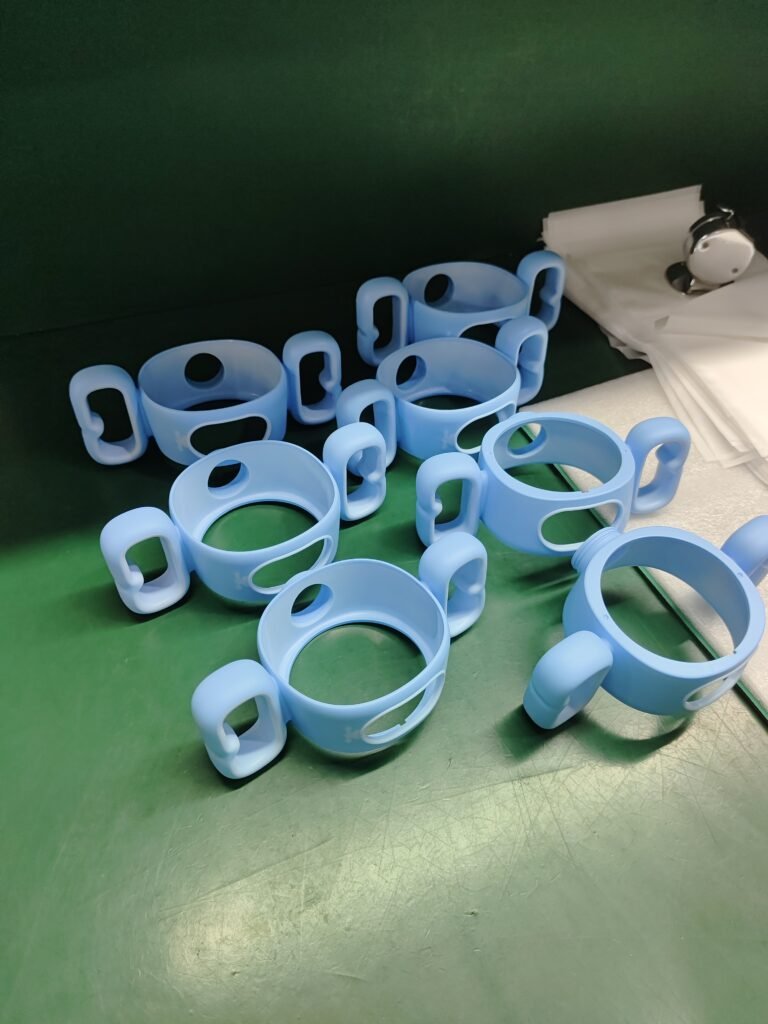

2. What industries commonly use aluminum molds?

- Consumer Electronics: Fast-turnaround casings for prototypes.

- Medical Devices: Low-volume production of surgical tool components.

- Automotive: Pre-production validation of interior trim parts.

3. What is the typical lifespan of an aluminum mold?

Aluminum molds last 5,000–20,000 cycles, depending on:

- Material: Abrasive resins (e.g., glass-filled nylon) reduce lifespan.

- Cooling: Efficient cooling systems extend longevity.

- Maintenance: Regular cleaning and polishing prevent wear.

4. How much does an aluminum mold cost?

Costs range from 1,500–1,500–30,000, influenced by:

- Complexity: Multi-cavity designs or side actions add 20–40%.

- Surface Finish: SPI-A1 (mirror finish) increases machining time.

- Size: Larger molds require more material and CNC hours.

5. What materials can be used?

- Plastics: ABS, PP, PC, and TPU (avoid glass-filled resins).

- Silicones: LSR for medical or food-grade applications.

- Limitations: High-temp materials (e.g., PEEK) may warp aluminum.

6. How precise are aluminum molds?

Aluminum molds achieve tolerances of ±0.05–0.1mm, suitable for most prototypes and non-critical parts. Steel molds are recommended for tighter tolerances (±0.01mm).

7. Can aluminum molds be modified for design changes?

Yes. Aluminum’s softness allows easier modifications:

- Minor changes (gate adjustments): 3–5 days, 300–300–1,000.

- Major revisions (cavity redesign): 1–2 weeks, 1,500–1,500–5,000.

8. How do I ensure quality when sourcing aluminum molds from overseas suppliers?

- Verify ISO 9001 certification and request T1 sample inspections.

- Use third-party QC services for dimensional checks (CMM reports).

- Ensure suppliers provide mold flow analysis to predict defects.

9. What maintenance is required for aluminum molds?

- Daily: Clean cavities with non-abrasive solvents.

- Weekly: Inspect and lubricate ejector pins.

- Post-Run: Polish surfaces to remove resin residue.

10. When should I transition from aluminum to steel molds?

Switch to steel when:

- Volume exceeds 10,000 units.

- Material abrasiveness demands higher durability.

- Tolerances need to be tighter than ±0.05mm.

Conclusion

“Aluminum molds offer unmatched cost and speed benefits for low-volume production. BFY Mold’s guide compares tooling costs, cycle times, and when to choose aluminum over steel. Optimize your project today.”