Introduction to Double Injection Molding

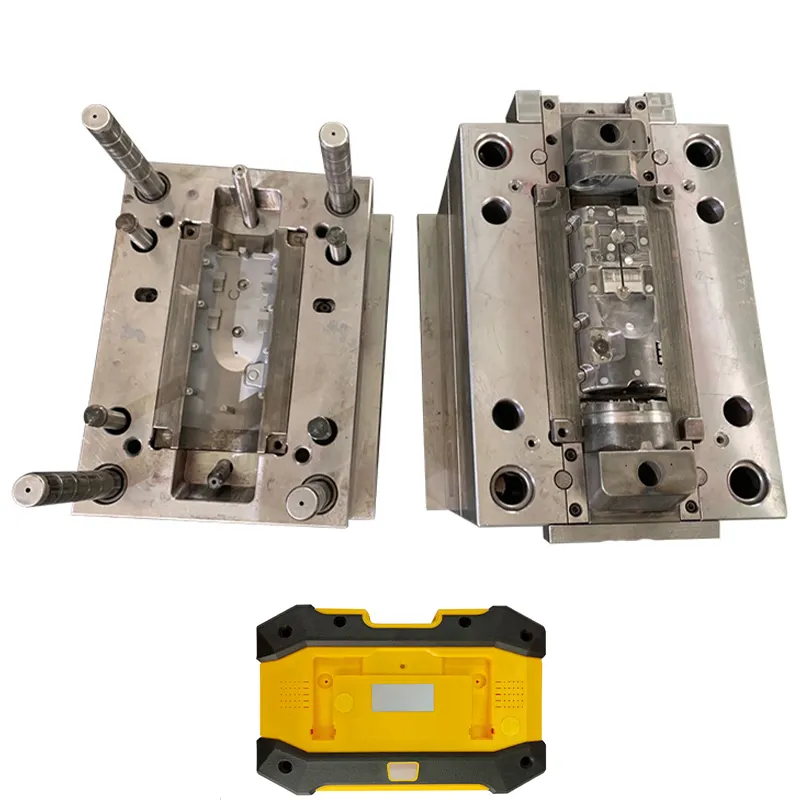

Double injection molding, also known as overmolding or two-shot molding, is a highly advanced injection molding process that allows two different materials to be injected into a single mold to create a multi-material, multi-colored component. This process involves the sequential injection of two separate materials into a mold cavity, which are then combined into one product, offering enhanced functionality and aesthetic appeal.

This innovative technique has found increasing applications across various industries, from automotive to medical devices, due to its ability to provide greater durability, improved ergonomics, and enhanced design versatility. If you’re looking for an efficient and cost-effective way to create complex parts with varied material properties, double injection molding is a process worth considering.

How Does Double Injection Molding Work?

The double injection molding process involves two distinct stages:

1. First Injection

The first material, usually a rigid plastic, is injected into the mold cavity. This material forms the base of the part or product. The mold is then cooled to solidify this first material.

2. Second Injection

After the first material has solidified, the mold is re-opened, and a second material—often a softer, more flexible polymer—is injected into the mold. The second material bonds with the first material, either by fusing with it or through mechanical interlocking, depending on the materials used.

The key to the success of this process is the compatibility of the materials being used, ensuring that they adhere to each other without delaminating.

Benefits of Double Injection Molding

1. Cost-Efficiency in Production

Although the initial setup for double injection molding can be more expensive due to the need for specialized molds and equipment, it can significantly reduce overall manufacturing costs in the long run. Since two materials are processed in a single molding cycle, this reduces the need for additional assembly steps and labor, thus lowering the overall production costs.

2. Improved Product Performance

By combining two different materials in a single part, manufacturers can leverage the unique properties of each material. For instance, a rigid outer layer can provide strength and durability, while a soft inner layer can offer flexibility or improve ergonomics. This dual-material approach is especially useful in applications like automotive parts, medical devices, and consumer goods, where both functionality and user comfort are important.

3. Enhanced Aesthetic and Design Flexibility

Double injection molding allows manufacturers to incorporate multiple colors or textures into a single part without the need for additional coating or painting processes. This not only saves time but also enhances the product’s aesthetic appeal. Additionally, the two-shot process provides more design freedom, enabling more intricate shapes and features than traditional single-material molding.

4. Improved Durability and Ergonomics

Parts made with double injection molding are often more durable and reliable due to the enhanced bonding between the two materials. For example, in the case of automotive parts, the combination of rigid and soft materials can result in components that are both strong and comfortable to handle. Similarly, medical devices such as syringes and handles can benefit from the ergonomic design afforded by the use of two different materials.

Key Applications of Double Injection Molding

Double injection molding is widely used across several industries due to its versatility. Some of the primary applications include:

- Automotive Industry: The automotive sector uses double injection molding to produce parts that require both strength and flexibility, such as dashboard components, handles, and seals. The ability to combine hard and soft materials in one part leads to lighter and more durable products.

- Medical Industry: Double injection molding is frequently used in the manufacturing of medical devices such as handles, casings, and surgical tools. By using two different materials, manufacturers can create ergonomic, comfortable, and durable products while meeting strict regulatory requirements.

- Consumer Goods: From kitchen gadgets to electronics, double injection molding is used to produce items that are both aesthetically pleasing and functional. By using two different materials, products can achieve a unique design or texture while enhancing user experience.

- Sports and Fitness: Sports equipment such as grips, handles, and protective gear benefits from the dual-material structure, providing a balance of toughness and comfort.

- Packaging: In packaging, particularly for cosmetics and pharmaceuticals, double injection molding helps create protective and visually appealing packaging that enhances both the safety and appearance of the product.

The Double Injection Molding Process: Step-by-Step

Step 1: Mold Design and Preparation Before the injection process begins, the mold is designed to accommodate two separate materials. The mold must be able to handle the complex injection process, which may include multiple injection gates, cooling systems, and an efficient ejection system. The precision of the mold design is critical to ensure a smooth production run.

Step 2: First Injection In the first phase of the process, the rigid material is injected into the mold cavity, forming the first part of the product. The mold is then cooled to allow the first material to solidify.

Step 3: Second Injection After the mold is re-opened, the second material is injected into the cavity. The second material bonds with the first material, either chemically or through mechanical interlocking, depending on the materials used. This bonding process is key to the success of double injection molding.

Step 4: Cooling and Ejection Once both materials have been injected and bonded, the mold is cooled, allowing the final product to solidify. The part is then ejected from the mold, completing the process.

Considerations and Challenges in Double Injection Molding

While double injection molding offers many advantages, it does come with some challenges. The process requires precise control over the injection temperature, pressure, and timing to ensure that the two materials bond properly without causing defects. Additionally, choosing the right combination of materials is crucial to ensure compatibility and optimal performance.

The complexity of the molding process also requires specialized equipment and tooling, which can increase the upfront investment. However, these challenges are often outweighed by the long-term benefits of reduced production time and enhanced product quality.

Why Choose BFY Mold for Your Injection Molding Needs?

At BFY Mold, we specialize in providing high-quality injection molding solutions, including double injection molding, for a variety of industries. With years of experience in mold manufacturing and processing, we are committed to delivering precision and efficiency in every project.

Our state-of-the-art facility enables us to handle both mass production and on-demand production, ensuring flexibility and scalability for your specific needs.

Our services include:

- Injection Molding Processing: Expertly crafted to meet the exact specifications of your project.

- Mold Manufacturing: High-quality molds for consistent and reliable production runs.

- Mass Production: Efficient production for large quantities of parts.

- On-Demand Production: Tailored solutions for small-scale or prototype production.

- CNC Machining and Mirror Spark: Precision tooling and finishing for high-quality surface finishes.

With our factory, we ensure that every project is handled with the utmost care and attention to detail. Let us help you bring your ideas to life with advanced injection molding techniques.

Conclusion

Double injection molding is a versatile and highly efficient process that combines the benefits of two materials into a single part. It offers numerous advantages, including cost savings, improved performance, and enhanced design flexibility, making it ideal for a wide range of industries. Whether you’re looking to create durable automotive parts, ergonomic medical devices, or innovative consumer goods, double injection molding can provide the perfect solution.

For expert molding services and customized solutions, trust BFY Mold to meet your production needs with precision and quality.