Injection molding is a manufacturing process that has become a cornerstone of modern production across numerous industries. Its ability to produce complex shapes with high precision and repeatability makes it an invaluable technique for manufacturers. So, how injection molding is utilized in various sectors, including automotive, medical, electronics, and consumer goods, highlighting its unique benefits to each industry?

Automotive Industry

Precision and Durability

The automotive industry relies heavily on injection molding to produce various components. From dashboard panels to engine components, it ensures that parts are made with precision and durability. The high repeatability of the process guarantees that each part meets the stringent quality standards required for automotive applications.

Cost Efficiency

Injection molding also provides cost benefits. The ability to produce large volumes of parts quickly and with minimal waste reduces production costs. This is particularly important in the automotive industry, where maintaining a balance between cost and quality is crucial.

Lightweight Components

Modern vehicles demand lightweight components to improve fuel efficiency and reduce emissions. It allows for the use of advanced plastic materials that are both strong and lightweight, contributing to the overall performance and efficiency of vehicles.

Medical Industry

High Precision and Cleanliness

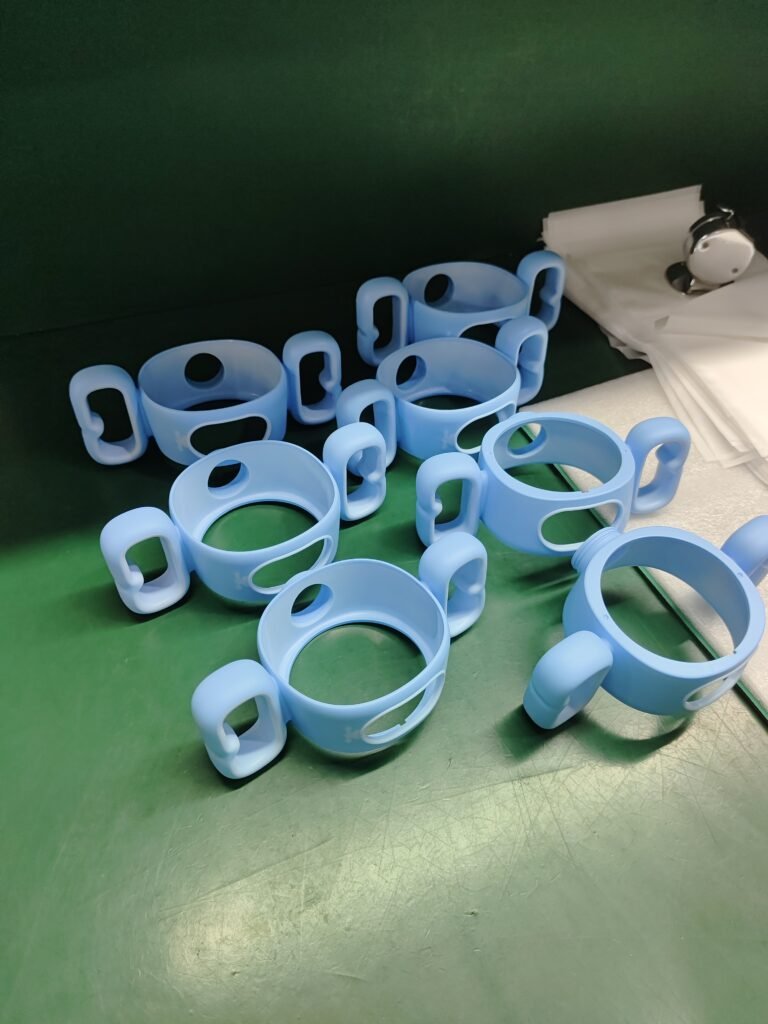

In the medical field, the precision and cleanliness of components are paramount. Injection molding offers the ability to produce highly intricate parts with tight tolerances, essential for medical devices and equipment. The process also supports the use of medical-grade plastics that meet stringent regulatory standards.

Sterilization Compatibility

Many medical components produced through injection molding are compatible with various sterilization methods, including autoclaving and gamma radiation. This compatibility ensures that the components can be safely used in sterile environments, such as hospitals and laboratories.

Customization and Innovation

The medical industry often requires customized solutions for specific applications. Injection molding allows for the rapid prototyping and production of custom parts, enabling medical device manufacturers to innovate and bring new products to market quickly.

Electronics Industry

Complex Geometries

The electronics industry benefits from injection molding’s ability to create parts with complex geometries. From housings for electronic devices to intricate connectors, the process can produce components that meet the exact specifications required for modern electronics.

Heat and Electrical Resistance

The molding materials can be selected for their specific properties, such as heat resistance and electrical insulation. This is crucial for electronic components that need to withstand high temperatures and prevent electrical interference.

Miniaturization

As electronic devices continue to shrink in size, the need for small, precise components grows. Injection molding supports the production of miniaturized parts without compromising on quality or performance, enabling the advancement of compact and efficient electronic products.

Consumer Goods Industry

Versatility and Design Freedom

The consumer goods industry is marked by a diverse range of products, from household items to toys. Injection molding provides the versatility needed to produce a wide variety of products with different shapes, sizes, and functionalities. The design freedom offered by the process allows manufacturers to create innovative and appealing products that meet consumer demands.

High-Volume Production

Consumer goods often require high-volume production to meet market demands. Injection molding is ideal for mass production, providing a cost-effective solution that maintains consistent quality across large quantities of products.

Sustainable Production

With growing awareness of environmental issues, the consumer goods industry is increasingly seeking sustainable production methods. It supports the use of recycled and biodegradable plastics, contributing to more environmentally friendly manufacturing practices.

Conclusion

Injection molding is a versatile and efficient manufacturing process that is critical in various industries, from automotive and medical to electronics and consumer goods. Its ability to produce high-quality, precise, and durable components makes it indispensable for modern production. At BFY Mold, we provide top-notch injection molding and mold manufacturing services, mass production, on-demand production, CNC machining, and mirror spark. With our factory and a commitment to excellence, we are ready to meet the diverse needs of our clients across different industries.

For more information about our services and how we can support your manufacturing needs, you can visit our website or contact us directly.

FAQs on the advantages of injection molding in common industries

1. How does injection molding benefit the automotive industry?

Injection molding produces lightweight, heat-resistant components (e.g., dashboards, connectors) with ±0.05mm precision, reducing vehicle weight by 15–20% for improved fuel efficiency.

2. Why is injection molding critical for medical devices?

ISO 13485-certified molding ensures sterile, biocompatible parts (e.g., syringe bodies, IV housings) using USP Class VI materials like PEEK and COC.

3. What makes injection molding ideal for electronics?

It creates ESD-safe, flame-retardant enclosures (UL 94 V-0) with tight tolerances (±0.02mm) for PCBs and connectors, ensuring EMI/RFI shielding.

4. How does injection molding optimize consumer goods production?

High-volume molding (50k+ units/day) delivers cost-effective, durable products (e.g., kitchenware, toys) in materials like PP and ABS at <$0.10/unit.

5. Which materials are best for automotive injection molding?

Glass-filled nylon (30% GF) for under-hood parts, ABS for interiors, and TPE for seals.

6. How to reduce costs in electronics molding?

Multi-cavity molds cut per-unit costs by 40%, while overmolding eliminates assembly steps.

7. What surface finishes are available for consumer goods?

Options include SPI-A2 (glossy), textured finishes (VDI 3400), and custom Pantone color matching.

8. How fast can BFY Mold deliver molded auto parts?

Prototype tooling in 10 days, mass production in 4–6 weeks with aluminum/steel molds.

About BFY Mold

BFY Mold is a leading provider of injection molding and mold manufacturing services. With our factory and a team of skilled professionals, we offer a range of services including mass production, on-demand production, CNC machining, and mirror spark. Our commitment to quality and customer satisfaction ensures that we deliver exceptional products that meet the highest standards. Contact us today to learn how we can support your manufacturing needs.