What is Injection Molding?

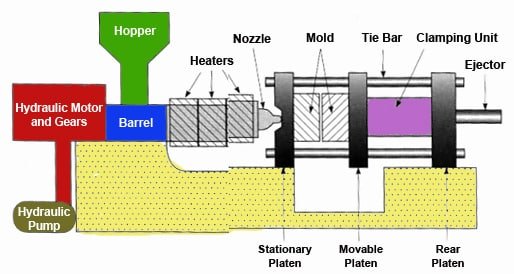

Injection molding, the traditional manufacturing method, has been around for quite some time. It involves melting a plastic material and injecting it into a mold cavity. Once the material cools and solidifies, the mold is opened to reveal the finished product.

Injection Molding Process

What is 3D Printing?

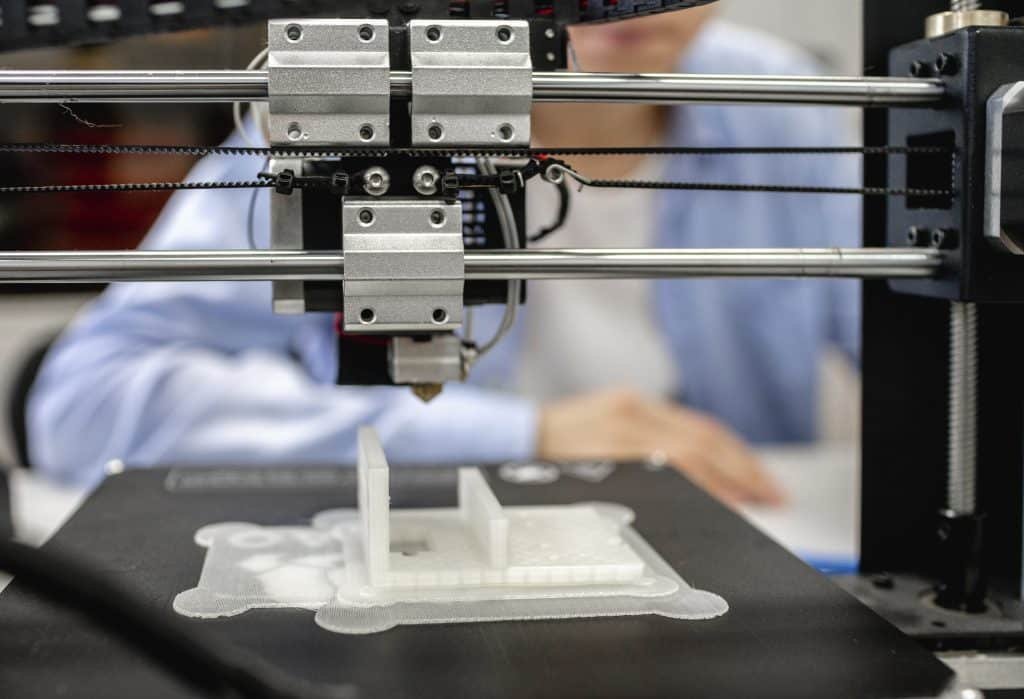

Also known as additive manufacturing, it builds up a product layer by layer from a digital model. Different technologies exist, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

3D Printing Process

Difference between Injection Molding and 3D printing

Here’s a comparison of injection molding and 3D printing in tabular form:

| Criteria | Injection Molding | 3D Printing |

| Volume of Production | Ideal for high-volume production. | Suitable for low to moderate production volumes. |

| Cost | Higher initial tooling costs, and lower per-unit costs for large quantities. | Lower initial setup costs, and higher per-unit costs. |

| Lead Time | Longer setup time due to mold creation. | Faster setup; suitable for rapid prototyping. |

| Material Selection | Wide range of materials, including plastics and some metals. | Limited material options; suitable for prototyping. |

| Complexity and Design Freedom | Well-suited for complex designs with some constraints. | Greater design freedom and flexibility for complex geometries. |

| Surface Finish | Smooth and polished surface finish. | Surface finish may vary, may require post-processing. |

| Tolerance and Precision | Higher precision and tighter tolerances. | Tolerances may vary depending on the printing technology. |

| Environmental Impact | May generate more waste during setup and material changes. | Can be more environmentally friendly for small-batch production. |

Conclusion

Keep in mind that the choice between these techniques should be based on your specific project requirements and priorities.

By considering these factors, you can gain a better understanding of which manufacturing method is more suitable for your specific project requirements. It’s often helpful to consult with experts or professionals in the field for tailored advice.

As a core technology in plastic manufacturing, the intricate injection molding process has strict requirements for both equipment and process parameters.

Injection Mold Company

A high-quality injection-molded product necessitates adherence to the steps of injection molding and precise control of the injection molding process parameters. So, what are you waiting for? Embark on your injection molding journey with BFY Mold now!