Introduction

In today’s highly competitive global market, speed is critical for business success. Companies in the United States are increasingly turning to China for plastic injection molding services, benefiting from cost-effective production, rapid turnaround times, and high-quality manufacturing. This partnership enables businesses to innovate faster, meet demand efficiently, and maintain their competitive edge.

In this blog post, we’ll explore how US businesses gain speed and efficiency by leveraging Chinese plastic injection molding services. We’ll also highlight key benefits, considerations, and how to maximize this global collaboration.

Why US Businesses Choose China for Plastic Injection Molding

1. Cost-Effectiveness Without Compromising Quality

One of the primary reasons US businesses outsource injection molding services to China is the significant cost advantage. The lower labor, materials, and infrastructure costs in China make it possible to produce high-quality parts at a fraction of the cost compared to domestic manufacturing.

Chinese manufacturers, like BFY Mold, leverage advanced technology and skilled labor to ensure quality standards comparable to those of US and European factories. As a result, they provide businesses with reliable and durable components.

2. Faster Turnaround Times

Speed is crucial for product development and market launches. China’s highly developed supply chain and manufacturing ecosystem enable quick production cycles. Plastic injection molding services offered by Chinese companies streamline processes such as:

- Prototype creation

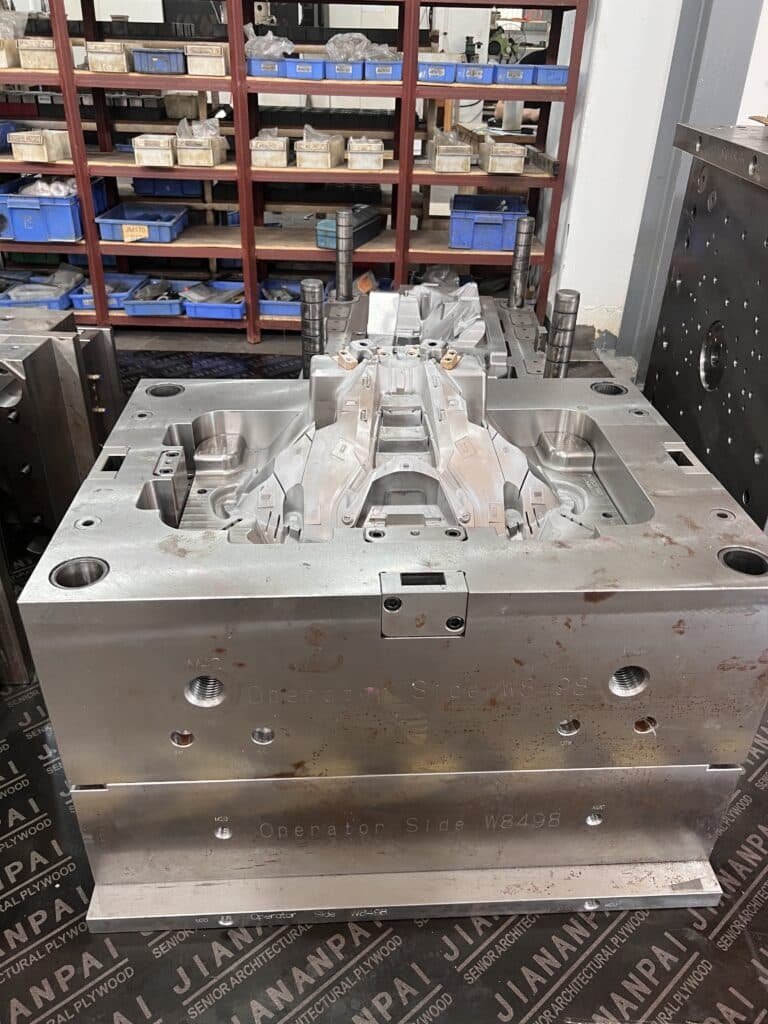

- Tooling and mold manufacturing

- Mass production

By outsourcing to China, US companies can drastically reduce lead times, accelerating the time it takes for products to reach the market.

3. Access to Advanced Manufacturing Capabilities

China’s injection molding and mold manufacturing facilities are equipped with cutting-edge technologies, including:

- CNC machining for precision parts.

- Mirror spark technology for ultra-smooth mold surfaces.

- Efficient on-demand production systems for flexible manufacturing.

These advanced capabilities allow businesses to produce complex designs, maintain consistent quality, and meet strict tolerances.

4. Scalability for High-Volume Production

Chinese injection molding companies excel at scaling up operations that require large-scale production while maintaining cost-effectiveness and quality. Extensive resource availability ensures that even large orders can be completed on time without compromising delivery times or standards.

Benefits of Partnering with Chinese Injection Molding Services

Streamlined Supply Chains

China’s mature manufacturing network supports a streamlined supply chain, minimizing delays caused by raw material shortages or logistical challenges. US companies benefit from a seamless flow of materials, production, and delivery.

Customization and Flexibility

Chinese manufacturers offer flexibility to cater to specific business needs, from custom mold designs to tailored production schedules. This adaptability is especially beneficial for industries requiring specialized solutions, such as medical devices, automotive components, and consumer goods.

Global Competitiveness

By reducing production costs and speeding up delivery times, US businesses can stay competitive in the global market. Lower expenses also enable companies to invest more in innovation and marketing, further strengthening their market position.

Considerations When Sourcing Plastic Injection Molding Services from China

1. Supplier Selection

Partnering with a reputable manufacturer is essential for ensuring quality and reliability. Look for companies with proven expertise in injection molding, CNC machining, and mass production, like BFY Mold.

2. Communication and Collaboration

Effective communication ensures that specifications, timelines, and quality standards are met. Many Chinese manufacturers provide English-speaking project managers and transparent processes to facilitate smooth collaboration.

3. Compliance with Standards

Ensure that the manufacturer adheres to international quality standards, such as ISO certifications, and is capable of meeting regulatory requirements for your industry.

4. Logistics and Shipping

Though China offers rapid production, shipping times can vary. Working with manufacturers that have experience in exporting to the US can help mitigate potential delays and ensure timely delivery.

How to Maximize the Benefits of Injection Molding Services

Start with Clear Specifications

Detailed designs and specifications help manufacturers deliver precise results. Use CAD files and prototypes to convey your requirements accurately.

Leverage Expertise

Partnering with experienced manufacturers like BFY Mold ensures access to expert advice on material selection, design optimization, and production methods.

Focus on Long-Term Relationships

Building a strong relationship with a reliable supplier fosters better collaboration, quality consistency, and trust over time.

Plan for Scalability

As your business grows, having a partner capable of scaling production ensures you can meet increasing demand without disruptions.

Why BFY Mold is Your Trusted Partner

At BFY Mold, we specialize in providing high-quality plastic injection molding services to businesses worldwide, including the United States. With a focus on precision, speed, and cost-effectiveness, we help companies bring their products to market faster and more efficiently.

Our main services include:

- Injection molding and mold manufacturing for various industries.

- Mass production for high-demand projects.

- On-demand production to meet customized needs.

- CNC machining and mirror spark technology for superior results.

With our state-of-the-art factory and a dedicated team of professionals, BFY Mold is committed to delivering excellence at every stage of the manufacturing process.

Conclusion

By leveraging plastic injection molding services from China, US businesses gain a competitive edge through cost savings, faster production times, and access to advanced manufacturing technologies. A trusted partner like BFY Mold can ensure quality, reliability, and efficiency, empowering your business to stay ahead in the global market.

If you’re ready to accelerate your growth with world-class manufacturing solutions, contact BFY Mold today.