What is Deep Hole Drilling?

Deep hole drilling is a machining process used to create holes significantly deeper than their diameters. This process is characterized by its ability to produce holes with a depth-to-diameter ratio greater than 10:1, although ratios as high as 100:1 are possible. Deep hole drilling is essential in industries where precision and accuracy in deep hole creation are critical. The process employs specialized drilling tools and techniques to achieve the desired depth and quality of the holes.

Part Manufacturing Process

It can be applied to a wide range of parts across various industries. Some of the most common parts that benefit from this process include:

Aerospace Components:

- Aircraft landing gear

- Hydraulic systems

- Fuel system components

Automotive Parts:

- Crankshafts

- Camshafts

- Connecting rods

- Transmission shafts

Medical Devices:

- Surgical instruments

- Implants

- Hypodermic needles

Oil and Gas Equipment:

- Drill collars

- Downhole tools

- Tubing and casing components

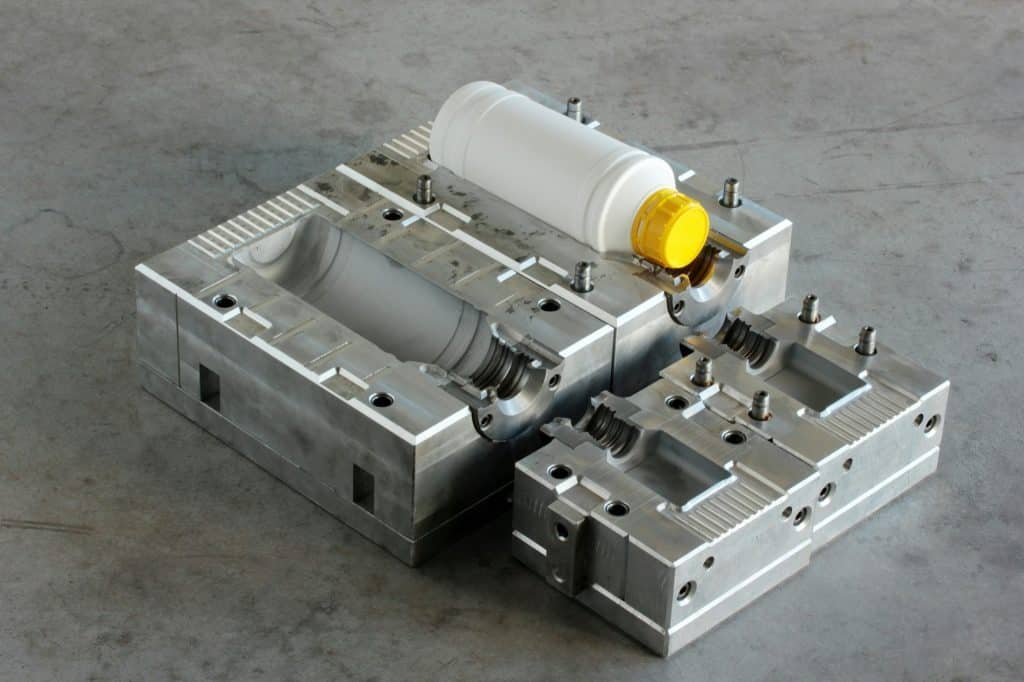

Mold and Die Components:

- Cooling channels in molds

- Ejector pins

- Core pins

Industrial Machinery:

- Machine tool spindles

- Hydraulic cylinders

- Pneumatic actuators

Advantages of Deep Hole Drilling

The process offers several advantages, making it the preferred choice for specific applications:

Precision and Accuracy:

Deep hole drilling ensures high precision and accuracy, with tight tolerances and minimal deviation from the intended path. This is crucial for parts requiring exact specifications and alignment.

Surface Finish:

The process produces excellent surface finishes, reducing the need for secondary operations such as reaming or honing. This is particularly beneficial for hydraulic and pneumatic systems where smooth surfaces are essential for proper functioning.

Efficiency:

It is an efficient process that allows for high material removal rates, reducing production time. Specialized tools and techniques enable faster drilling without compromising quality.

Versatility:

This process can be applied to various materials, including metals, alloys, and composites. The versatility makes it suitable for diverse industries with different material requirements.

Cost-Effectiveness:

By minimizing the need for multiple machining operations and ensuring high-quality finishes, deep-hole drilling can reduce overall production costs. The ability to produce deep holes in a single operation also contributes to cost savings.

Enhanced Mechanical Properties:

It can improve the mechanical properties of certain parts by introducing compressive residual stresses, which enhance fatigue resistance and strength.

Application Scenarios

It is utilized in various application scenarios requiring deep, precise holes. Some of the key application scenarios include:

- Aerospace Industry:

- Hydraulic and Fuel Systems: Deep hole drilling is critical in manufacturing hydraulic and fuel system components that require precise, deep holes for fluid transfer and structural integrity.

- Structural Components: Aircraft landing gear and structural supports often need deep holes for weight reduction without compromising strength.

- Engine Components: Crankshafts and camshafts require deep, precise holes for lubrication and cooling channels. Deep hole drilling ensures these components function efficiently and reliably.

- Transmission Systems: Deep holes in transmission shafts are necessary for optimal fluid flow and mechanical performance.

- Surgical Instruments: Precision and cleanliness are paramount in medical instruments. Sometimes provides the required accuracy for instruments like hypodermic needles and surgical drills.

- Implants: Medical implants often require deep holes for secure attachment and bodily integration.

- Oil and Gas Industry:

- Downhole Tools: Drilling equipment used in the oil and gas industry needs deep holes for effective operation in harsh environments. Deep hole drilling ensures the durability and functionality of these tools.

- Tubing and Casing: It is essential for producing tubing and casing components that can withstand high pressures and temperatures.

- Cooling Channels: Molds and dies used in plastic injection molding require deep cooling channels to regulate temperature and improve the quality of molded parts. Deep hole drilling provides the necessary precision for these channels.

- Ejector and Core Pins: These components need deep holes for secure placement and effective functioning in the molding process.

- Industrial Machinery:

- Hydraulic and Pneumatic Actuators: These actuators rely on deep holes for fluid passage and mechanical movement. Deep hole drilling ensures their reliability and performance.

- Machine Tool Spindles: Deep holes are required in spindles for the passage of coolant and lubrication. Precision in these holes ensures the efficient operation of machine tools.

Conclusion

Deep hole drilling is an indispensable machining process for creating precise, deep holes in a variety of materials and components. Its ability to produce high-quality holes with excellent surface finishes and tight tolerances makes it a preferred choice in aerospace, automotive, medical, oil and gas, mold and die-making, and industrial machinery. The advantages of deep hole drilling, including precision, efficiency, versatility, and cost-effectiveness, ensure its continued relevance in modern manufacturing. By understanding the parts that can be processed, the benefits offered, and the application scenarios, manufacturers can leverage deep-hole drilling to enhance the quality and performance of their products.