3D printing and injection molding are both valuable manufacturing techniques, but they serve different purposes and have distinct advantages and limitations. Whether 3D printing will replace injection molding depends on several factors, including the application, production volume, material requirements, and cost considerations.

Comparison of 3D Printing vs. Injection Molding

| Criteria | 3D Printing | Injection Molding |

| Production Volume | Low to Medium (ideal for small to moderate quantities) | High (best for mass production with thousands to millions of parts) |

| Setup Costs | Low (no need for molds, suitable for small batches) | High (requires expensive molds, economical for large runs) |

| Per-Unit Cost | High for large volumes (costs remain relatively constant per unit) | Low for large volumes (cost per unit decreases as production volume increases) |

| Material Variety | Limited (fewer materials with specific properties are available) | Wide Range (supports various plastics, metals, and other materials) |

| Design Flexibility | High (excellent for complex and custom designs) | Medium (designs are limited by mold constraints and need for draft angles) |

| Surface Finish | Variable (depends on printing technology, often requires post-processing) | Excellent (smooth, consistent finish with less need for post-processing) |

| Lead Time for Prototypes | Short (can produce prototypes in hours to days) | Long (time-consuming mold design and manufacturing process) |

| Complex Geometries | Excellent (can create intricate and detailed designs with ease) | Limited (complex designs may require more complicated or multi-part molds) |

| Material Waste | Low (additive process with minimal waste) | High (material waste from mold setup and potential scrap during production) |

| Durability of Parts | Varies (depends on the material and printing process used) | High (produces durable parts with consistent mechanical properties) |

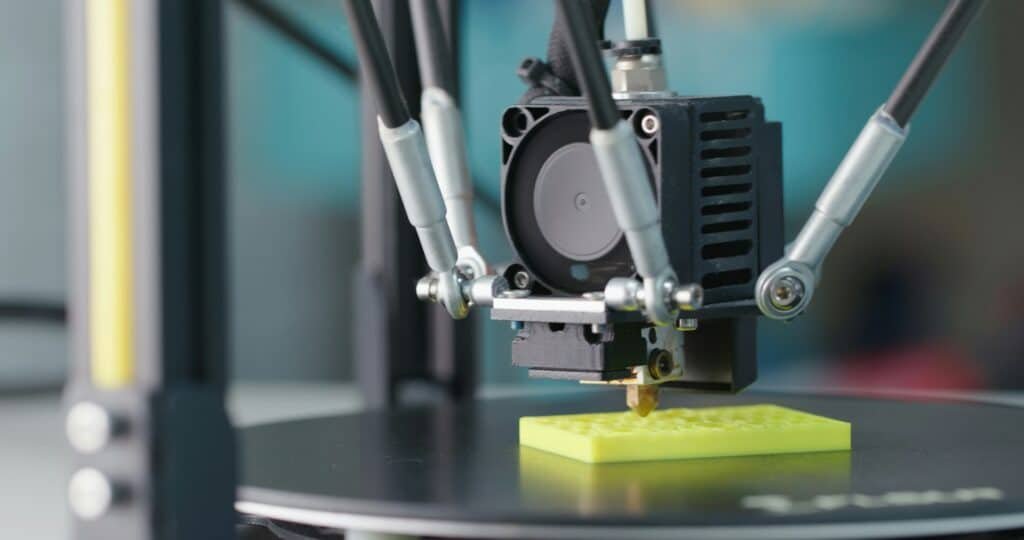

- 3D Printing is best for applications requiring rapid prototyping, custom parts, complex geometries, and low to medium production volumes. It excels in flexibility and is ideal for on-demand manufacturing.

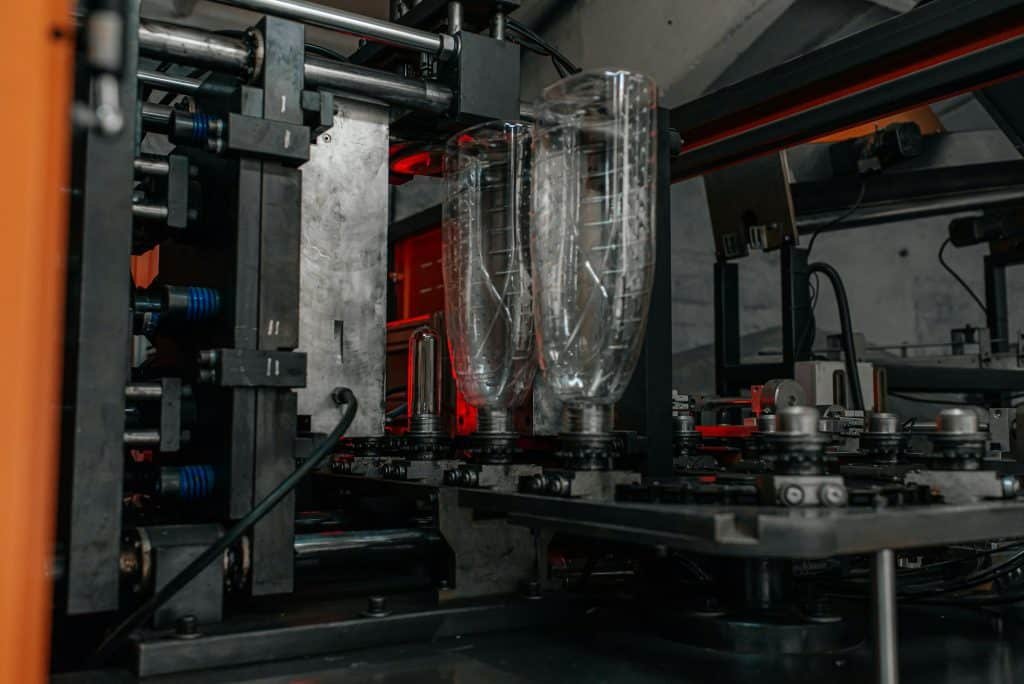

- Injection Molding is the preferred choice for high-volume production, especially when consistent quality, durability, and low per-unit costs are required. It is ideal for mass production, durable goods, and precision components.

Use Cases for 3D Printing vs. Injection Molding

| Use Case | 3D Printing | Injection Molding |

| Prototyping and Product Development | Rapidly creating prototypes, quick design iteration, and testing form and fit. | Not ideal due to high setup costs and longer lead times for mold creation. |

| Custom and Complex Geometries | Producing intricate designs and custom parts with high complexity. | Limited by mold design constraints; suitable for simpler geometries. |

| Low-Volume Production and Short Runs | Cost-effective for small batches or limited production runs. | Economically inefficient for low volumes due to high mold costs. |

| On-Demand Manufacturing and Spare Parts | Ideal for producing parts as needed, reducing inventory and storage costs. | Less flexible for on-demand production; better suited for planned mass production. |

| Educational and Research Purposes | Widely used in educational settings and research labs for experimental projects. | Rarely used for education due to high cost and complexity. |

| Mass Production of Plastic Parts | Not cost-effective for high volumes; slower production speed. | Ideal for mass production with low per-unit costs and high efficiency. |

| Medical Devices and High-Precision Components | Suitable for custom medical implants and prototypes with specific geometries. | Perfect for high-precision, sterile, and durable medical devices. |

| Durable Consumer Goods | Suitable for custom or short-run consumer goods with unique designs. | Best for high-volume, durable products like toys, kitchenware, and tools. |

| Packaging and Disposable Products | Not economical for high-volume packaging needs. | Highly efficient for mass-producing packaging materials and disposable products. |

| Automotive Parts and Components | Used for prototyping automotive parts or small custom components. | Best for large-scale production of durable, high-precision automotive components. |

Key Takeaways

- Production Volume: Injection molding is ideal for large-scale production due to its high speed and low cost per unit for large volumes. In contrast, 3D printing is more suitable for low to medium volumes.

- Cost Efficiency: The cost of 3D printing remains relatively constant per unit, making it more suitable for small batches or custom parts. Injection molding has high upfront costs but becomes more economical with larger production runs.

- Material and Part Properties: Injection molding offers a broader range of materials with better mechanical properties and finishes. 3D printing is improving but is still more limited in this regard.

- Design Flexibility: 3D printing excels in producing complex, customized designs without the need for molds, making it ideal for prototypes and unique parts.

- Waste and Sustainability: 3D printing generates less material waste as an additive process, while injection molding can produce more waste but often recycles excess materials.

Conclusion

3D printing and injection molding serve different purposes and are suited for distinct use cases. While 3D printing is ideal for low-volume, custom, and complex parts, injection molding is preferred for high-volume production with consistent quality and material properties. By understanding the strengths of each method, businesses can make more informed decisions about which technology to use based on their specific needs and production goals.