Introduction

Choosing between ABS and PVC plastics for manufacturing or DIY Projects can be difficult. Each has a different role due to their unique differences in strength, cost, safety, and applications, but at the same time, they are both common thermoplastics. This guide thoroughly examines ABS vs. PVC to help you choose the best material for your project.

What is ABS Plastic?

ABS (Acrylonitrile Butadiene Styrene) is a lightweight, impact-resistant thermoplastic known for its versatility.

Key Properties of ABS Plastic

| Property | Description |

| Durability | High impact resistance, even at low temperatures. |

| Heat Resistance | Softens at approximately 221°F (105°C). |

| Machinability | Easy to cut, sand, or glue. |

| Safety | Generally food-safe but may release fumes when melted. |

Common Uses of ABS Plastic

- Automotive parts (dashboards, trim)

- Consumer goods (LEGO bricks, electronics housings)

- 3D printing filaments

What is PVC Plastic?

PVC (Polyvinyl Chloride) is a rigid or flexible thermoplastic known for its chemical resistance and affordability.

Key Properties of PVC Plastic

| Property | Description |

| Chemical Resistance | Withstands acids, oils, and alkalis. |

| Flame Retardancy | Self-extinguishing properties. |

| Safety Concerns | Contains phthalates in flexible forms; rigid PVC is BPA-free. |

Common Uses of PVC Plastic

- Plumbing pipes and fittings

- Medical tubing and IV bags

- Electrical cable insulation

ABS vs. PVC: Head-to-Head Comparison

Strength and Durability

| Feature | ABS | PVC |

| Impact Resistance | High | Moderate |

| Tensile Strength | Moderate | High |

| Flexibility | Rigid but impact-resistant | Can be rigid or flexible |

Choose ABS for mechanical parts and PVC for chemical-heavy settings.

Temperature Tolerance

| Feature | ABS | PVC |

| Maximum Heat Resistance | 221°F (105°C) | 140°F (60°C) |

| Performance in Cold Temperatures | Good | Moderate |

PVC suits moderate-heat scenarios; ABS is better for low-temperature durability.

Cost and Availability

| Feature | ABS | PVC |

| Material Cost | Slightly higher | More affordable |

| Availability | Widely available | Common in bulk orders |

PVC wins for budget-friendly bulk orders.

Safety and Environmental Impact

| Feature | ABS | PVC |

| Recyclability | Recyclable (#7 plastic) | Difficult to recycle |

| Fume Release When Burned | Moderate | High (toxic fumes) |

ABS is safer for indoor use; PVC demands careful handling.

Case Study: ABS vs. PVC in Automotive Manufacturing

A leading auto parts manufacturer tested both ABS and PVC for interior trim components:

| Feature | ABS | PVC |

| Breakage Rate | 30% lower | Higher |

| Crash Test Performance | Passed | Failed (brittle) |

| Final Choice | ABS | Rejected |

Takeaway: ABS’s durability makes it ideal for automotive applications.

How to Choose Between ABS and PVC

Ask these questions:

| Question | Best Choice |

| Will the part face impacts or vibrations? | ABS |

| Is chemical resistance critical? | PVC |

| Is the project budget-sensitive? | PVC |

| Are there safety or recycling concerns? | ABS |

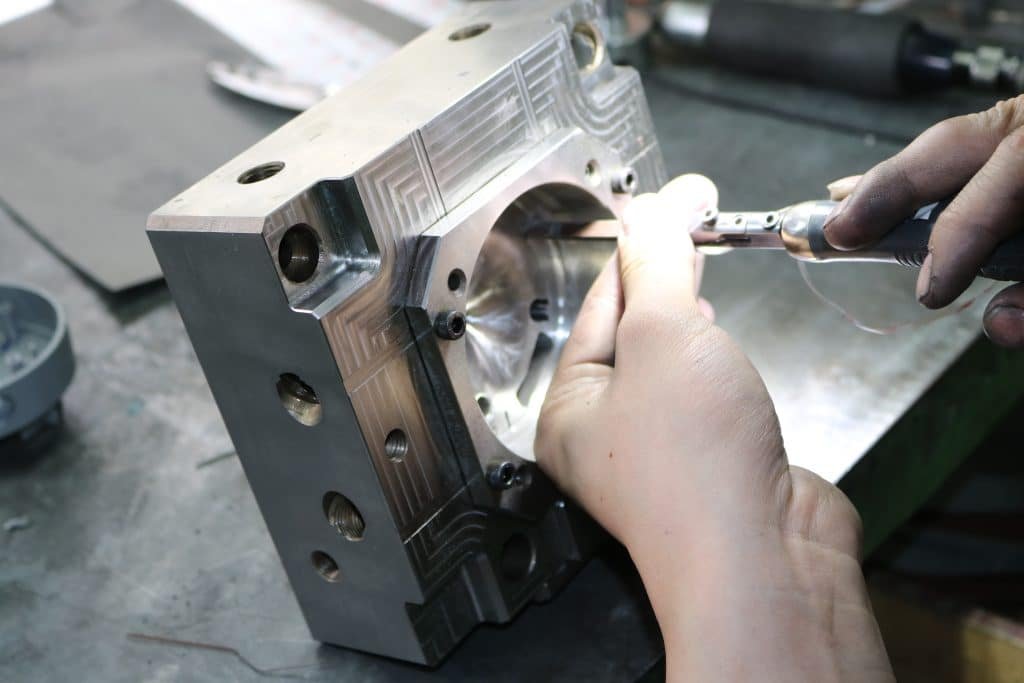

About BFY Mold: Your Partner in Precision Plastic Manufacturing

At BFY Mold, we specialize in custom ABS plastic injection molding solutions tailored to your project’s needs. With over 20 years of expertise, we offer:

Our Services

- Material Consulting: Expert guidance on choosing ABS, PVC, or advanced polymers.

- High-Precision Tooling: CNC-machined molds for complex geometries.

- Eco-Friendly Practices: Recycling programs for ABS and PVC waste.

Why Choose BFY Mold?

| Feature | Benefit |

| ISO 9001-Certified Quality | Consistent, high-quality manufacturing |

| Fast Turnaround | Prototyping to mass production in 4–6 weeks |

| Global Clientele | Trusted by automotive, medical, and consumer goods industries |

Contact Us today to discuss your project and request a free quote!